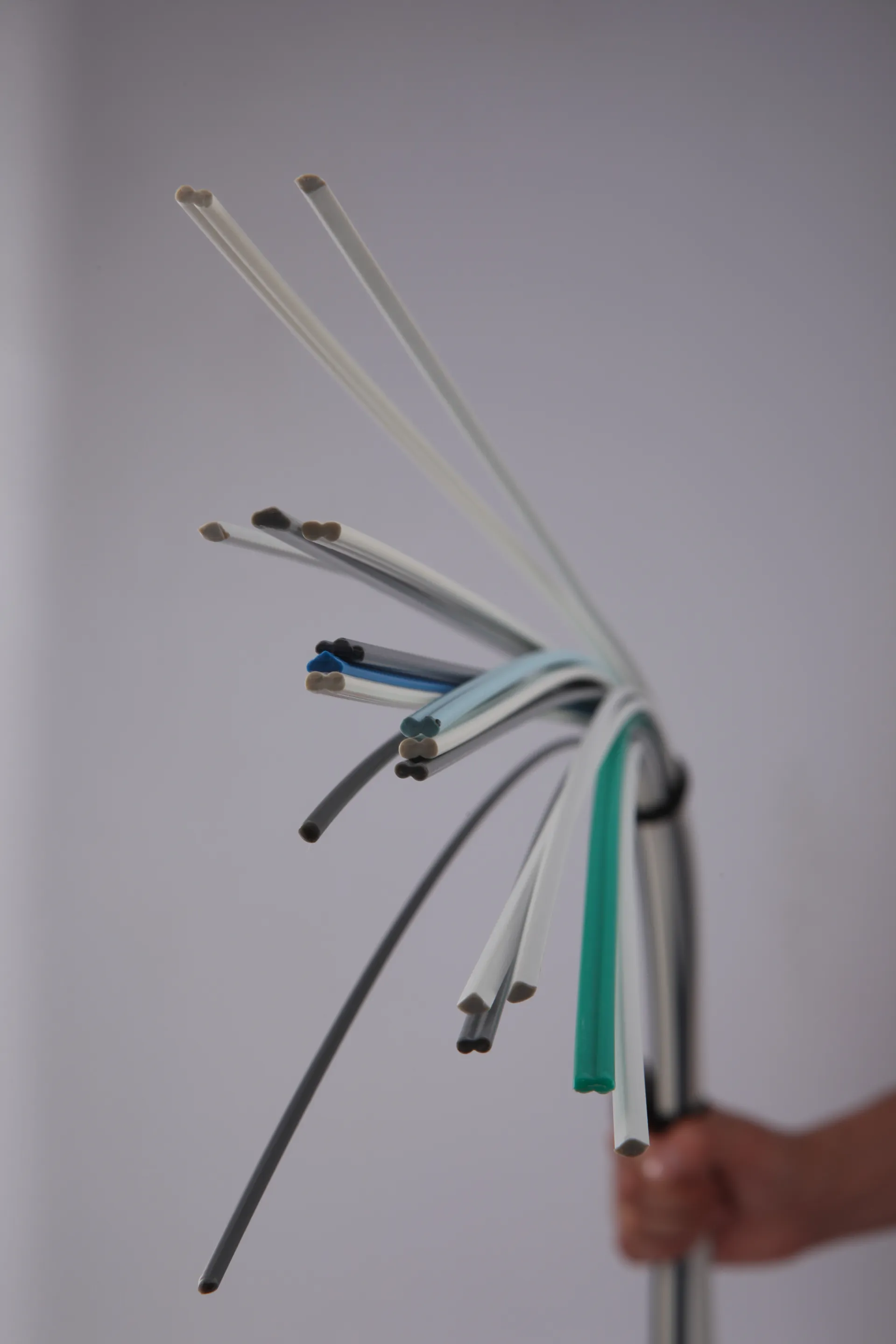

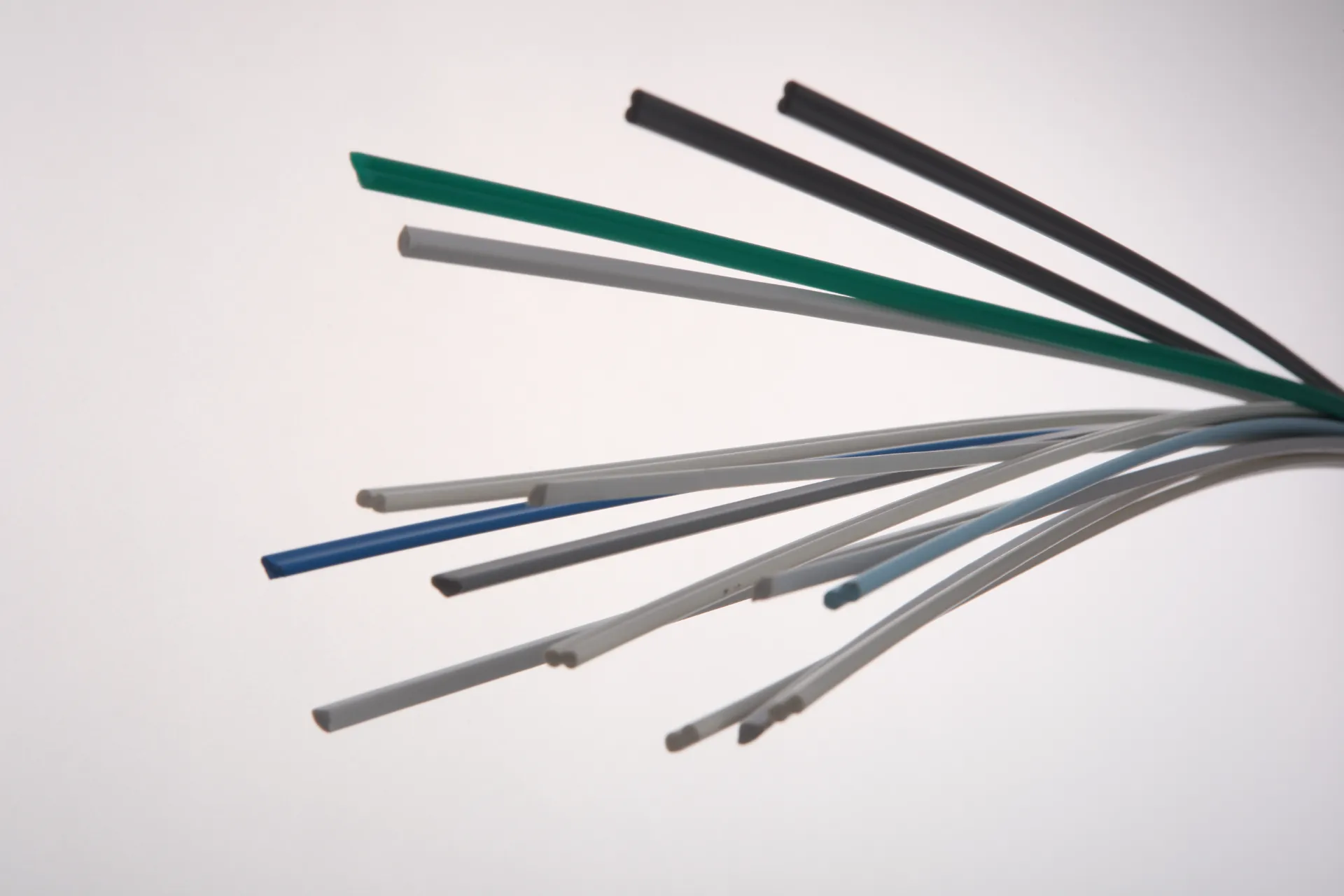

Produk Beskrywing

PVC welding rod is PVC resin as the main raw material, the extrusion of solid strip

Products.The product is designed for PVC product construction welding use,

specifications of 2.5-4.0mm, 1000mm long, varieties of single root, double root and

so on.

Main production equipment

1. extruder;

2. electrode cutting machine.

Production Process

Kneading is carried out in an ordinary Z-type kneader or a high-speed kneader. When using 45mm extruder, the screw speed is controlled in 15~24r/min. The temperature

of the first section of the extruder is generally 160~170 ° C, the temperature of the

second section is 170~180 ° C, and the head temperature is between 170~ 90 ° C.

Cooling is carried out in the cooling water tank, usually divided into two stages of

cooling, the first stage is cooled by hot water spray, the water temperature is 40~60℃, the second stage is cooled by cold water. The welding rod is cut at room temperature after cooling.

Characteristic

1.Acid-proof;

2.Salty-proof;

3.Water proof;

4.non-poisonous;

5.Anti-corrossion;

6.Low flammability;

7.Reliable electrical insulation;

8.Excellent welding properties;

9.Excellent chemical and corrosion resistance.

Verpakking: in lengte of in rolle per plastieksak.

Certificate of PVC welding rod :

ROHS.

Aansoeke

PVC welding rods is mainly used for welding by hand extrusion welder or heat air blower, the PVC welding rods can be devided into high density and low density. At the same time, the product can also be used in chemical treatment units, water tanks, industrial systems, etc. Used with plastic extrusion welder to weld the plastic container, plastic plates, pipes and so on.