Pasipatan fisik

|

Test Standard (Q/BLD2007-04) |

Unit |

Nilai has |

|

| Fisik | |||

| Kapadetan |

≤1.50 |

g/cm3 |

1.45 |

| Mékanis | |||

| Kakuatan regangan |

≥48 |

Mpa |

50 |

| Elongation |

≥10 |

% |

11 |

| Kakuatan Dampak |

≥10 |

Mpa |

11 |

| Termal | |||

| Vicat Softening Suhu |

≥70 |

°C |

76.8 |

| Distortion temperature |

≥68 |

°C |

68 |

| Kimia | |||

| 35%±1% (v/v) HCI |

±4 |

g/ cm2 |

+2 |

| 30%±1% (v/v) H2KITU4 |

±3 |

g/ cm2 |

+1 |

| 40%±1% (v/v) HNO3 |

±3 |

g/ cm2 |

+1 |

| 40%±1% (v/v) NaOH |

±3 |

g/ cm2 |

+1 |

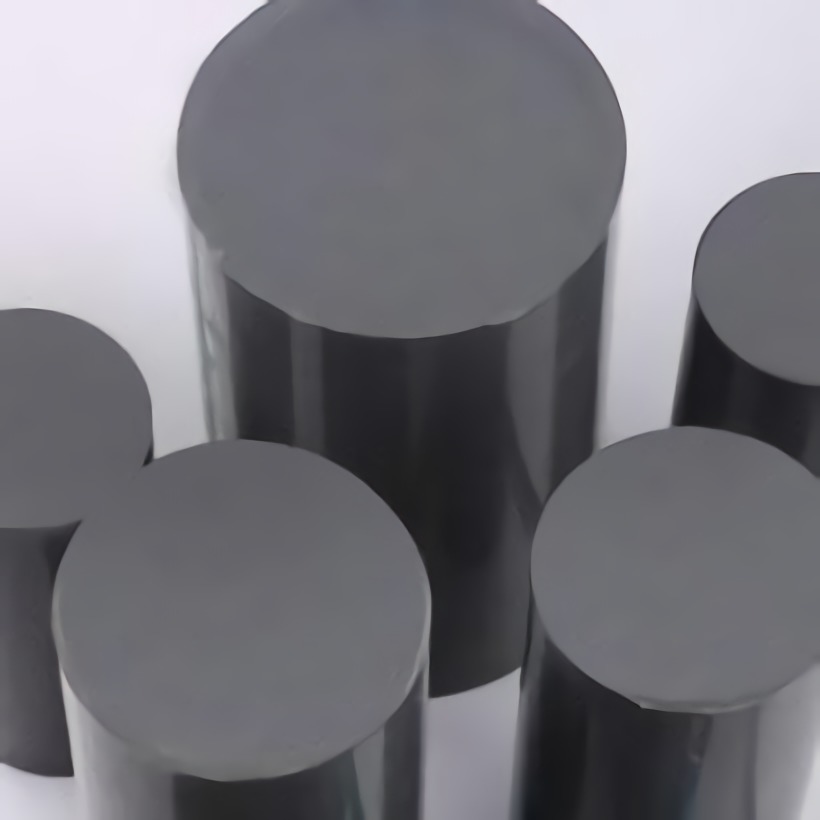

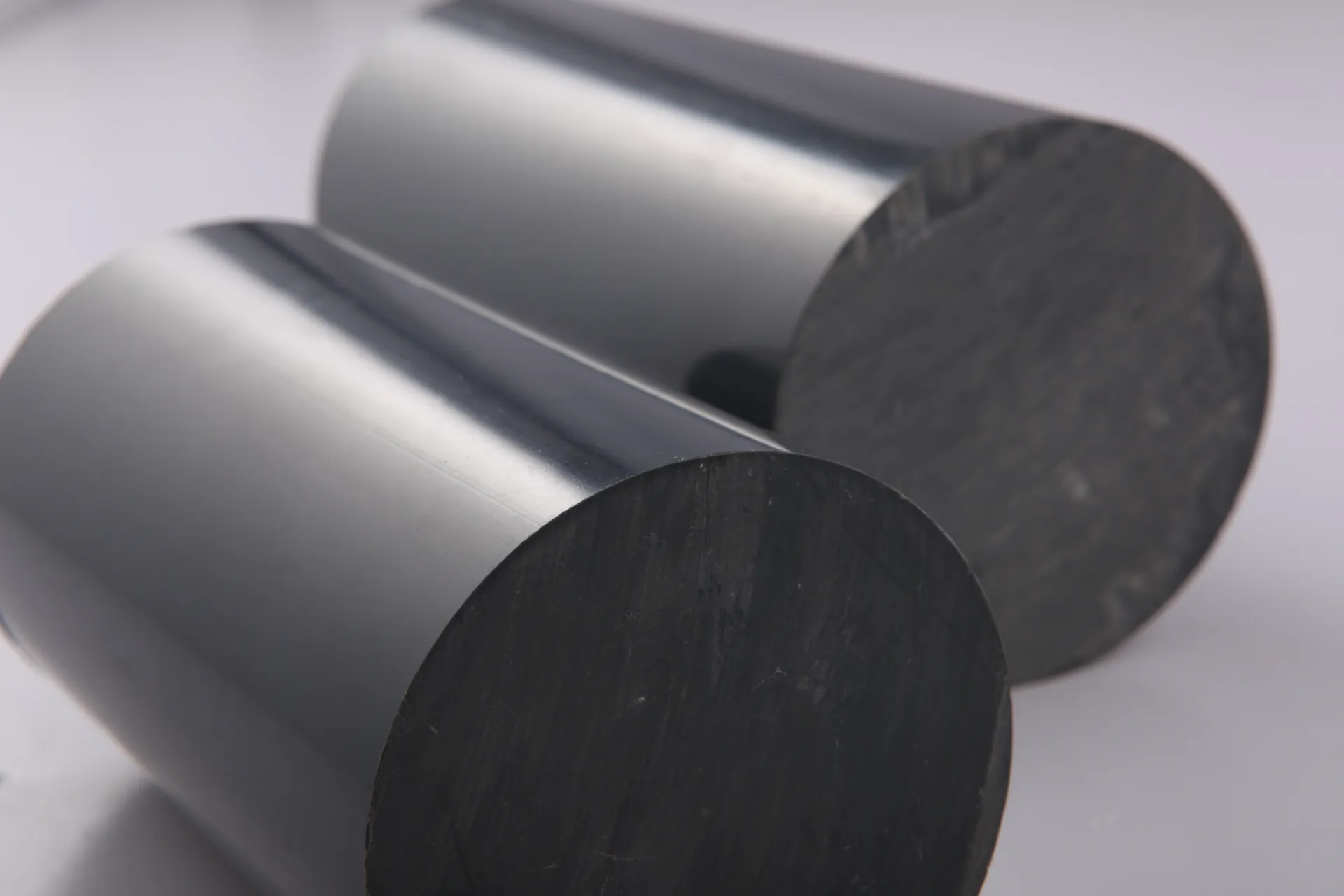

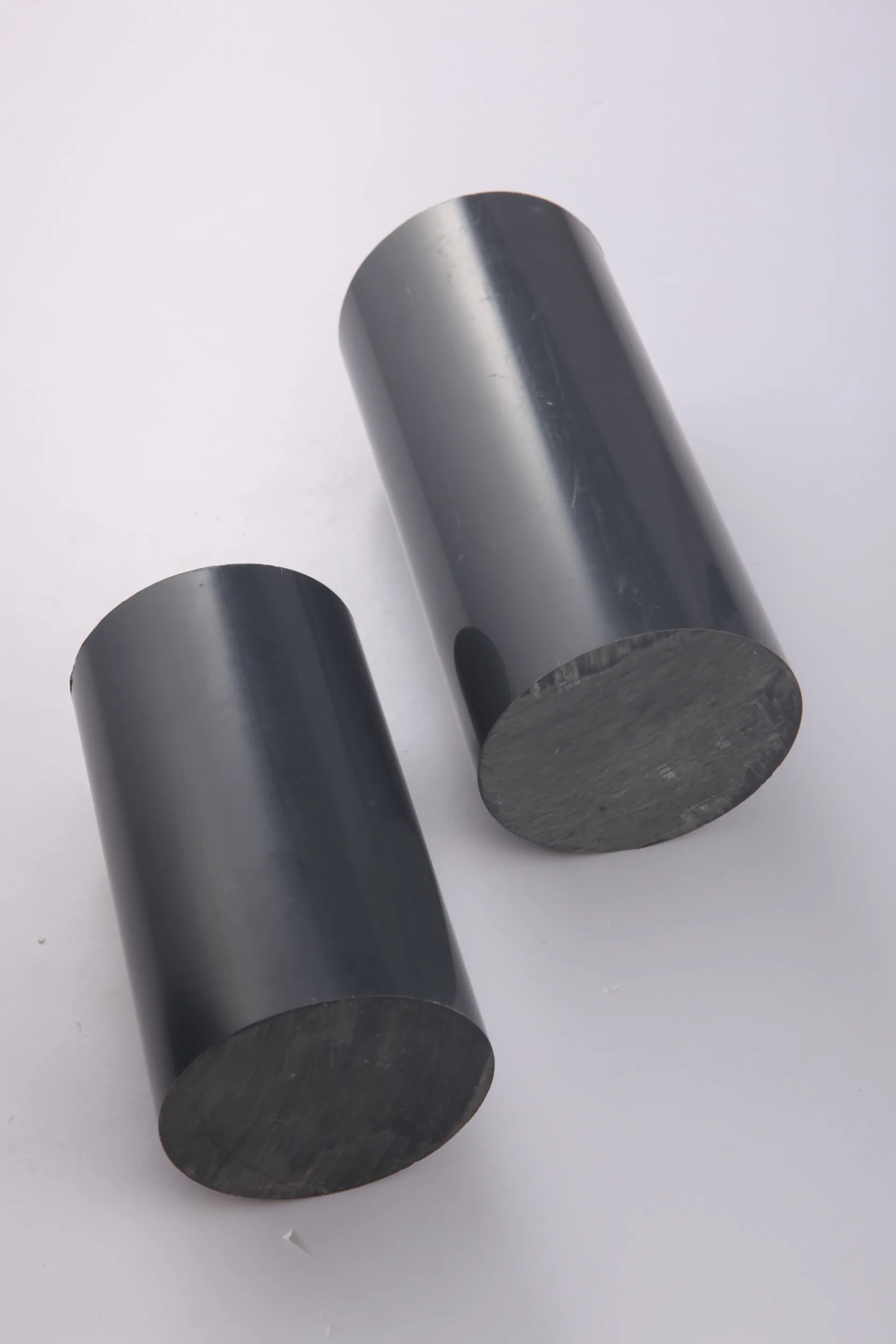

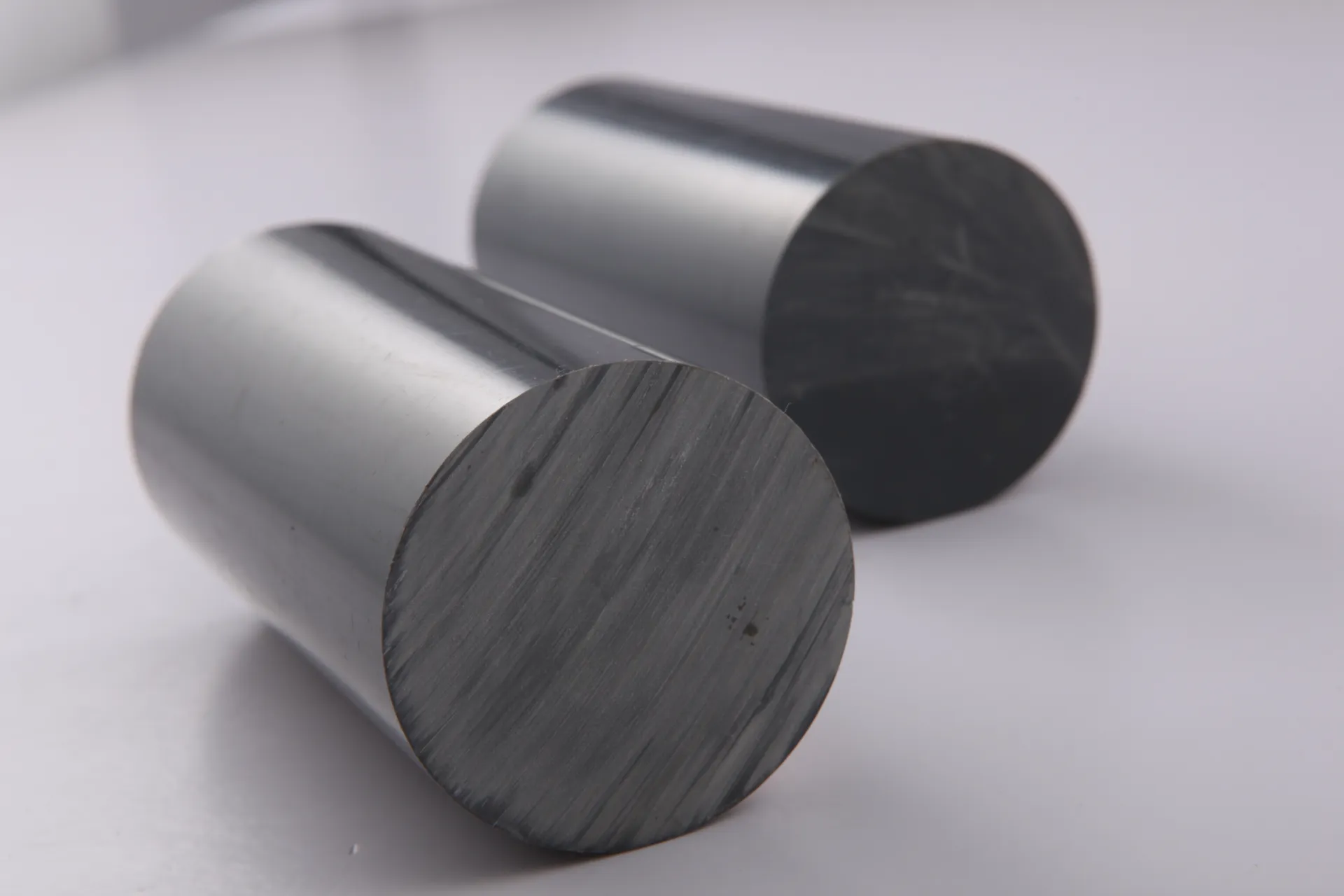

Panjelasan Produk

PVC rod buleud dijieun kalawan parawan polyvinyl chloride (PVC) résin, penstabil, pelumas, plasticizer, filler, dampak modifier, pigmén jeung aditif lianna. Ieu kalawan rupa tiis tahan, asam & alkali tahan, weldable sarta sipat anti korosi alus. Sagedengeun ti eta, sipat fisik na leuwih hade tinimbang karét sarta bahan coiled lianna. Hal ieu loba dipaké dina industri kimia jeung galvanization. Sapertos lapisan sél éléktrolitik, segel insulasi listrik, mesin cuci punching jsb.

Ciri

Rigidity tinggi;

Low flammability;

Penampilan geulis;

formability alus teuing;

karasa permukaan tinggi;

Insulasi listrik anu dipercaya;

Kinerja tahan Gores anu saé,

Alus kimiawi sarta lalawanan korosi;

Résistansi dampak sareng résistansi kana pangleyur kimiawi;

kinerja pinunjul.

Sertipikat tina PVC rod buleud

ROHS.

Urang Sunda

Our company adopts environment-friendly raw materials. Strictly control the production process, from raw materials to the factory layer quality inspection.The experimental testing follows the international quality management and certification system to ensure the quality of products.

Perusahaan kami nyetél sababaraha percobaan mandiri, kalayan tingkat otomatisasi alat produksi anu luhur, unggal taun pikeun investasi seueur artos, ngenalkeun bakat sareng téknologi, gaduh kakuatan panalungtikan ilmiah anu kuat.

Aplikasi

PVC rod buleud geus loba dipaké dina produksi asam sulfat, panyalindungan lingkungan jeung minyak, industri kimia, sarta dina serat kimiawi, apoték, kulit, ngalelep, kayaning industri manufaktur ogé geus angka nu gede ngarupakeun aplikasi.