Lub cev muaj zog

|

Test Standard (Q/BLD2007-04) |

Chav tsev |

Tus nqi |

|

| Lub cev | |||

| Qhov ntom |

≤1.50 |

g/cm3 |

1.45 |

| Neeg kho tshuab | |||

| Tensile zog |

≥48 |

Mpa |

50 |

| Elongation |

≥10 |

% |

11 |

| Kev cuam tshuam lub zog |

≥10 |

Mpa |

11 |

| Kub | |||

| Vicat Softening Kub |

≥70 |

°C |

76.8 |

| Distortion temperature |

≥68 |

°C |

68 |

| Tshuaj | |||

| 35%±1% (v/v) HCI |

±4 |

g/ cm2 |

+2 |

| 30%±1% (v/v) H2YOG4 |

±3 |

g/ cm2 |

+1 |

| 40%±1% (v/v) HNO3 |

±3 |

g/ cm2 |

+1 |

| 40%±1% (v/v) NaOH |

±3 |

g/ cm2 |

+1 |

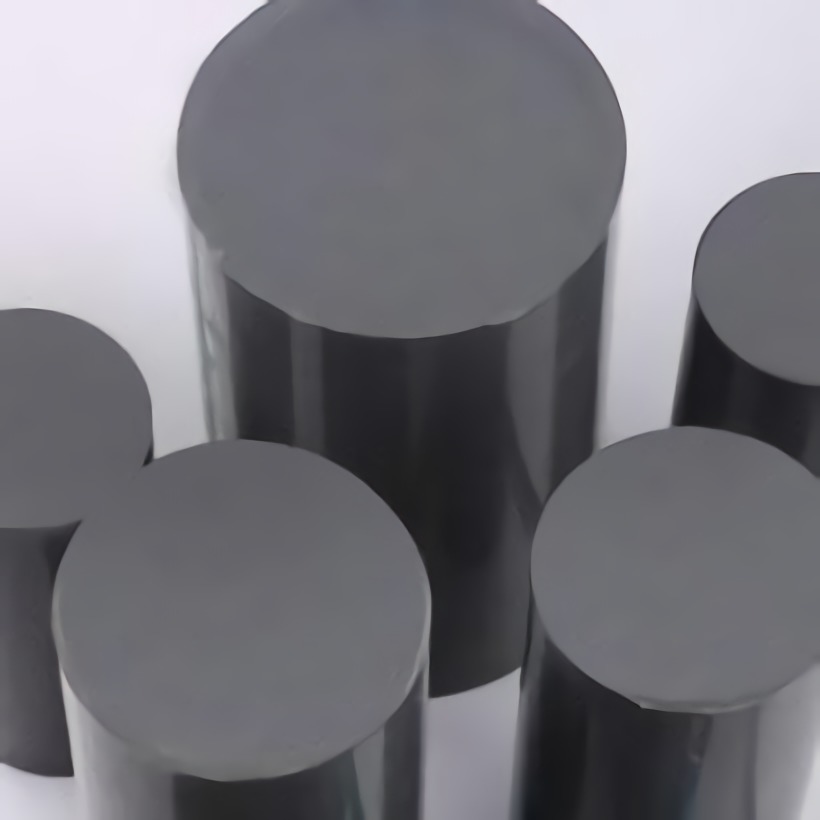

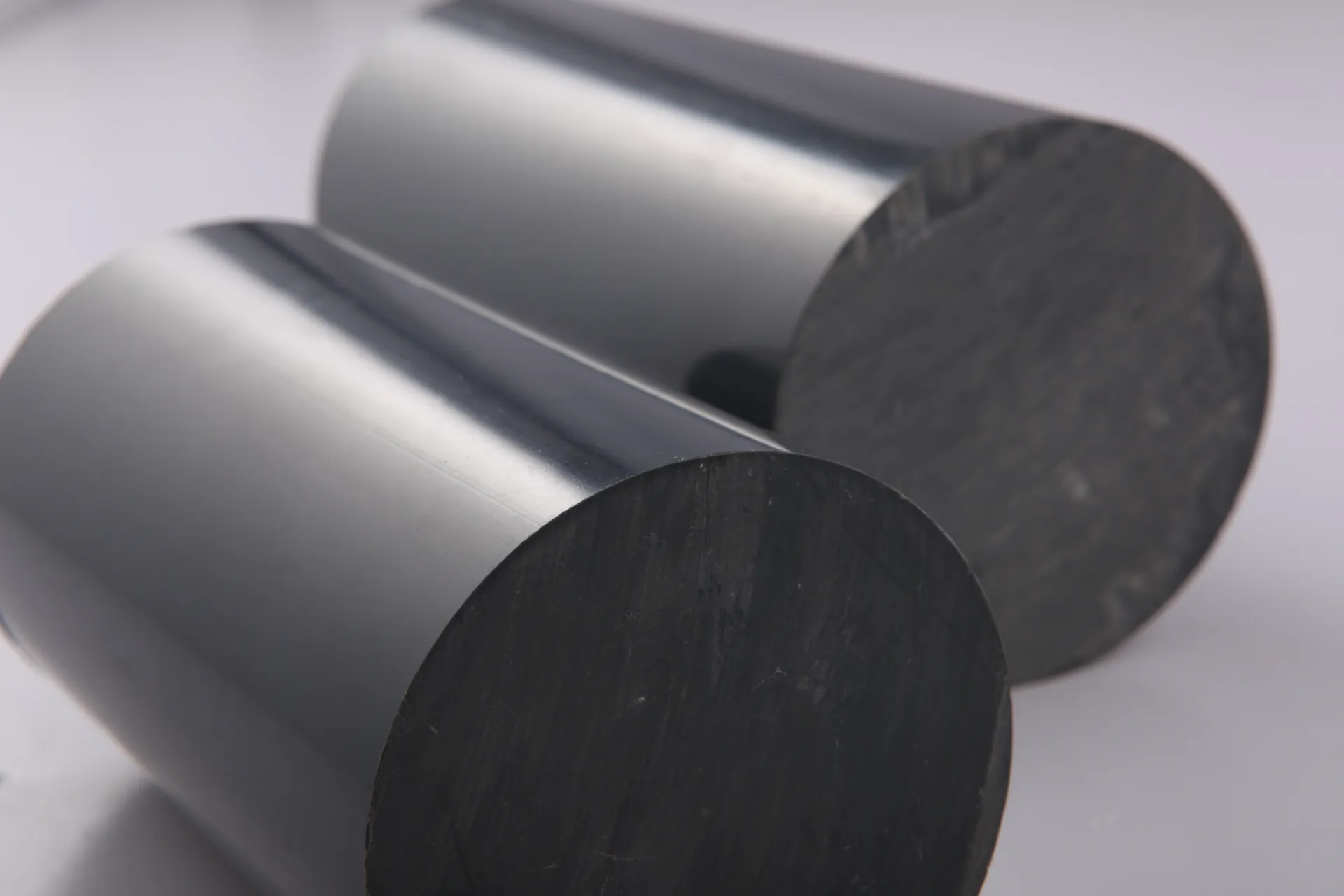

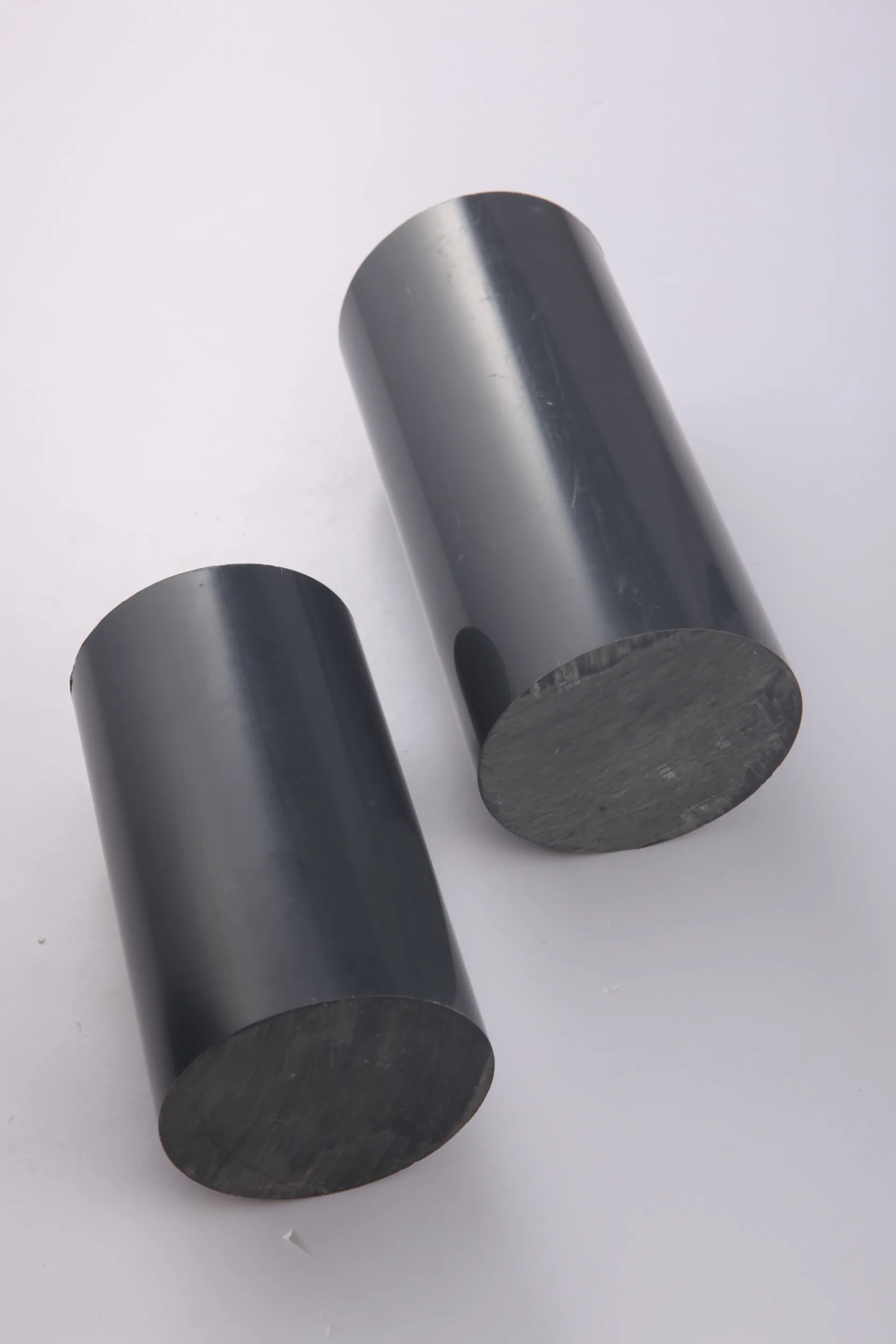

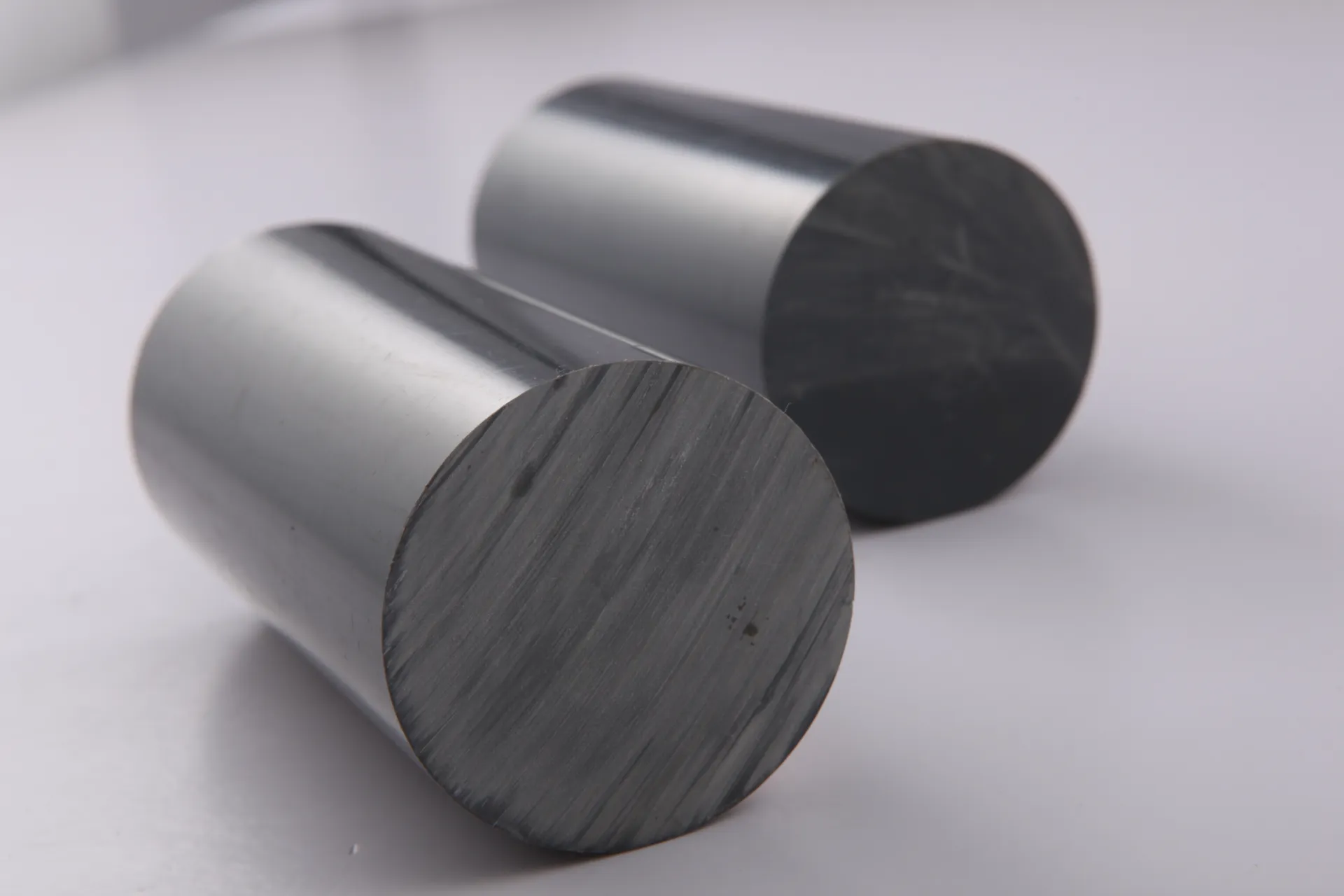

Product Description

PVC round rods yog tsim nrog nkauj xwb polyvinyl chloride (PVC) resin, stabilizer, lubricant, plasticizer, muab tub lim, cuam tshuam kev hloov pauv, xim thiab lwm yam khoom ntxiv. Nws yog nrog zoo txias resistant, acid & alkali resistant, weldable thiab zoo anti-corrosion khoom. Tsis tas li ntawd, nws lub cev muaj zog zoo dua li roj hmab thiab lwm yam khoom siv coiled. Nws yog dav siv nyob rau hauv tshuaj thiab galvanization kev lag luam. Xws li electrolytic cell hauv ob sab phlu, hluav taws xob insulating seals, punching washer thiab lwm yam.

Yam ntxwv

Siab rigidity;

Tsawg flammability;

Cov tsos zoo nkauj;

Formability zoo heev;

High deg hardness;

Txhim khu kev qha hluav taws xob rwb thaiv tsev;

Zoo heev Scratch resistant kev ua tau zoo,

Cov tshuaj zoo heev thiab corrosion kuj;

Kev cuam tshuam tsis kam thiab ua haujlwm rau cov kuab tshuaj lom neeg;

Kev ua tau zoo.

Daim ntawv pov thawj ntawm PVC round pas nrig

ROHS.

R&D

Our company adopts environment-friendly raw materials. Strictly control the production process, from raw materials to the factory layer quality inspection.The experimental testing follows the international quality management and certification system to ensure the quality of products.

Peb lub tuam txhab teeb tsa ntau qhov kev sim ywj pheej, nrog rau qib siab ntawm automation ntawm cov khoom siv ntau lawm, txhua txhua xyoo los nqis peev nyiaj ntau, kev qhia txog kev txawj ntse thiab thev naus laus zis, muaj zog tshawb fawb txog kev tshawb fawb.

Daim ntawv thov

PVC round rods tau siv dav hauv kev tsim cov sulfuric acid, kev tiv thaiv ib puag ncig thiab cov roj, tshuaj lom neeg kev lag luam, thiab nyob rau hauv cov tshuaj fiber ntau, khw muag tshuaj, tawv, xim, xws li kev lag luam kev lag luam kuj tau siv ntau yam.