Njirimara anụ ahụ

|

Test Standard (Q/BLD2007-04) |

Nkeji |

Uru a na-ahụkarị |

|

| Anụ ahụ | |||

| Njupụta |

≤1.50 |

g/cm3 |

1.45 |

| Mechanical | |||

| Ike ọdụdọ |

≥48 |

Mpa |

50 |

| Ogologo oge |

≥10 |

% |

11 |

| Mmetụta Mmetụta |

≥10 |

Mpa |

11 |

| Thermal | |||

| Okpomọkụ na-eme ka Vicat dị nro |

≥70 |

Celsius C |

76.8 |

| Distortion temperature |

≥68 |

Celsius C |

68 |

| Chemical | |||

| 35%±1% (v/v) HCI |

±4 |

g/ cm2 |

+2 |

| 30%±1% (v/v) H2SO4 |

±3 |

g/ cm2 |

+1 |

| 40%±1% (v/v) HNO3 |

±3 |

g/ cm2 |

+1 |

| 40%±1% (v/v) NaOH |

±3 |

g/ cm2 |

+1 |

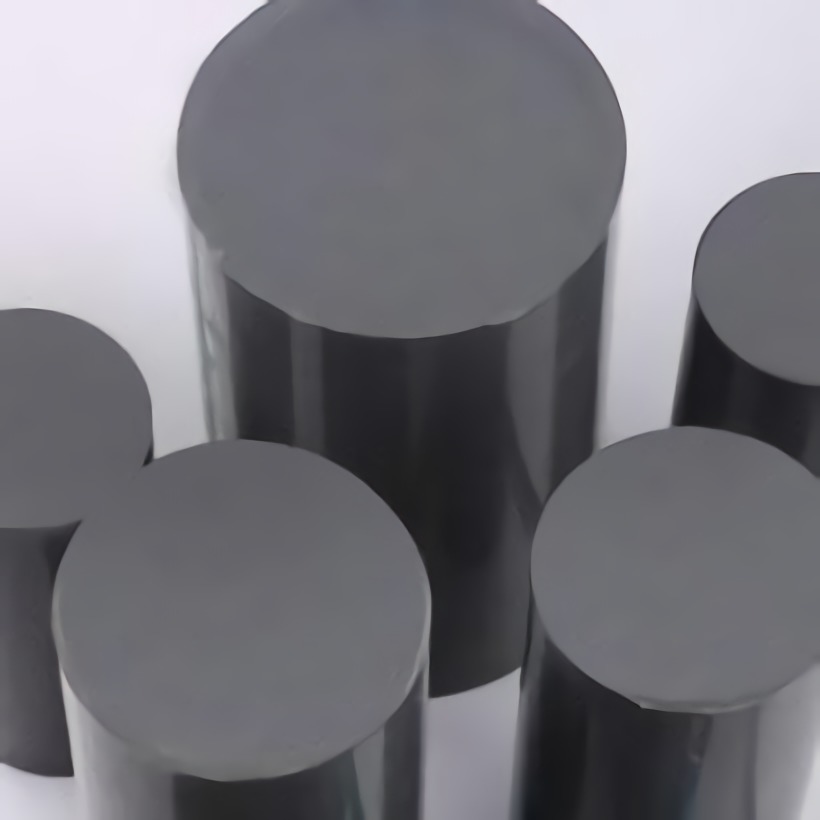

Nkọwa ngwaahịa

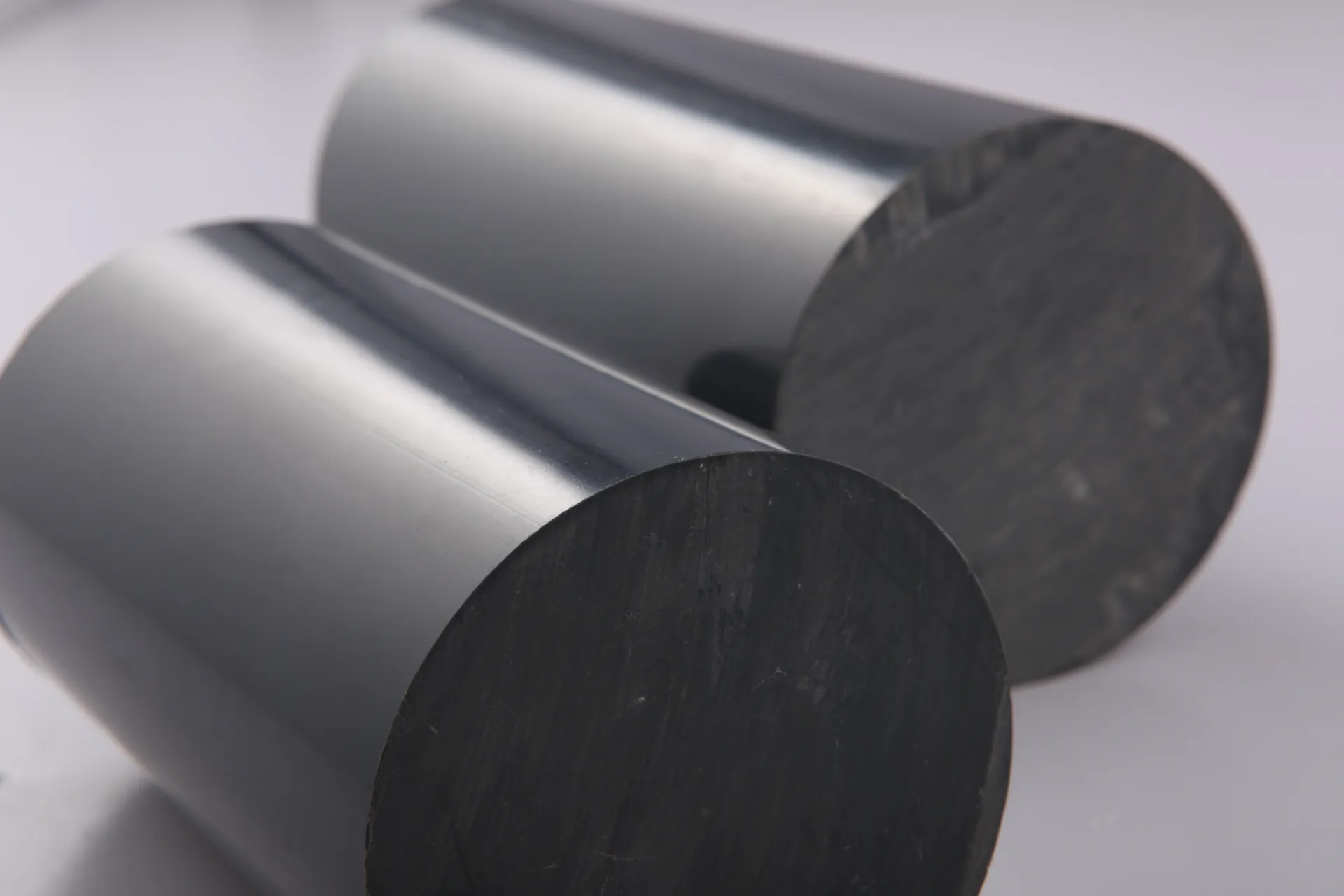

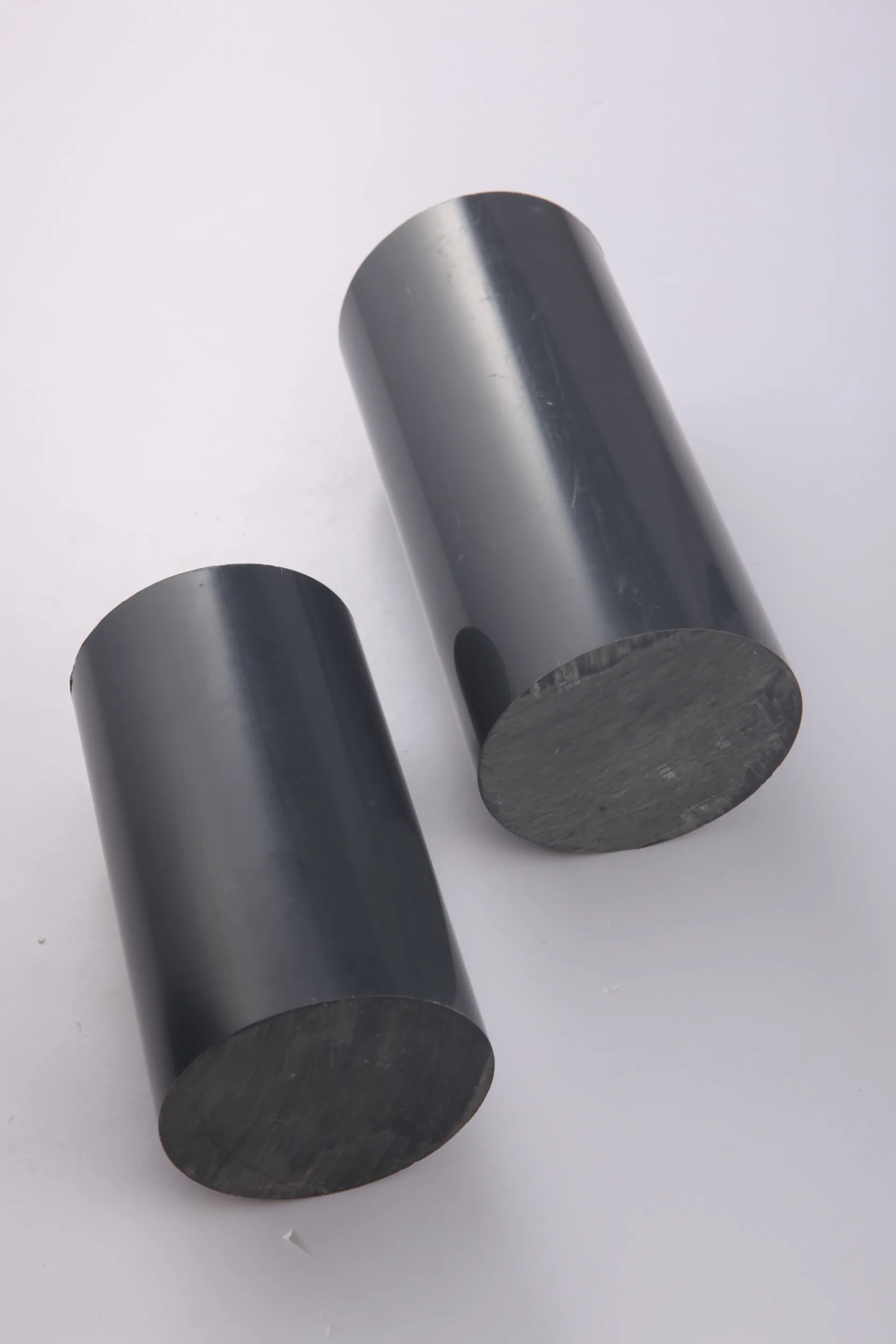

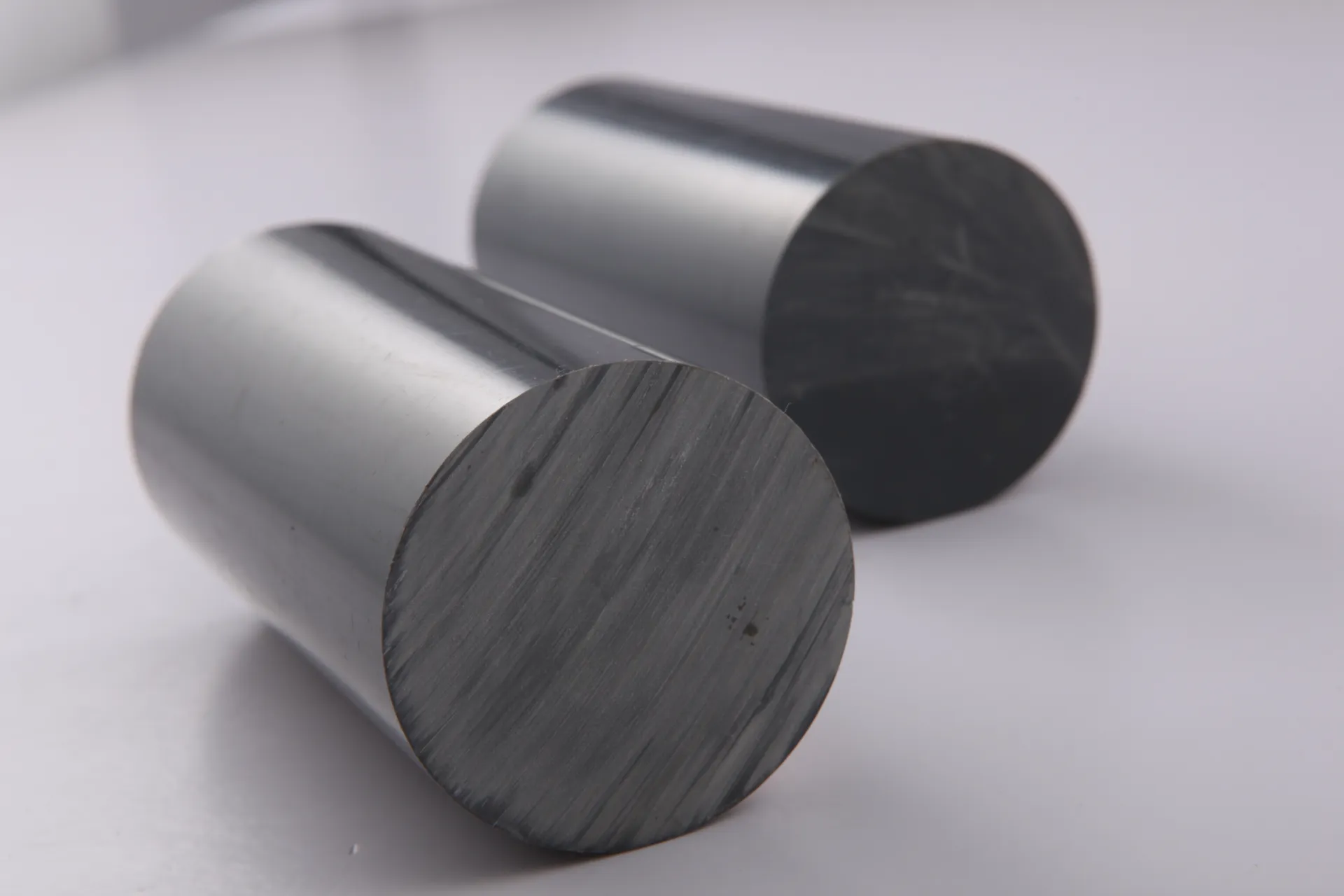

A na-eji mkpanaka polyvinyl chloride (PVC) na-amaghị nwoke mee mkpanaka, stabilizer, lubricant, plasticizer, filler, modifier mmetụta, pigmenti na ihe mgbakwunye ndị ọzọ. Ọ nwere ezigbo mgbochi oyi, acid & alkali na-eguzogide, weldable na ezigbo ihe mgbochi corrosion. E wezụga nke ahụ, ihe onwunwe ya dị mma karịa rọba na ihe ndị ọzọ agbakọtara. A na-ejikarị ya eme ihe na kemịkalụ na ụlọ ọrụ galvanization. Dị ka ihe mkpuchi cell electrolytic, mkpuchi mkpuchi eletriki, igwe ọkpọ ọkpọ wdg.

Njirimara

Nnukwu isi ike;

Obere ire ọkụ;

Ọdịdị mara mma;

Ọdịdị dị mma;

Isi ike elu elu;

Ihe mkpuchi ọkụ a pụrụ ịdabere na ya;

Ọmarịcha arụmọrụ na-eguzogide Scratch,

Ezigbo kemịkalụ na nguzogide corrosion;

Mmetụta mmetụta na iguzogide ihe mgbaze kemịkalụ;

Ọrụ pụtara ìhè.

Akwụkwọ nke PVC gburugburu mkpanaka

ROHS.

R&D

Our company adopts environment-friendly raw materials. Strictly control the production process, from raw materials to the factory layer quality inspection.The experimental testing follows the international quality management and certification system to ensure the quality of products.

Ụlọ ọrụ anyị guzobere ọnụ ọgụgụ nke nnwale onwe onye, nwere ogo dị elu nke akpaaka nke akụrụngwa mmepụta, kwa afọ iji tinye ego buru ibu, iwebata talent na teknụzụ, nwere ike nyocha sayensị siri ike.

Ngwa

PVC gburugburu mkpara e ọtụtụ-eji na mmepụta nke sulfuric acid, gburugburu ebe obibi nchebe na mmanụ, chemical ụlọ ọrụ, na kemịkalụ eriri, ahịa ọgwụ, akpụkpọ anụ, esiji, dị ka n'ichepụta ụlọ ọrụ nwekwara a nnukwu ọnụ ọgụgụ nke ngwa.