Sifat Fisik

|

Test Standard (Q/BLD2007-04) |

Unit |

Nilai Khas |

|

| fisik | |||

| Kapadhetan |

≤1.50 |

g/cm3 |

1.45 |

| Mekanik | |||

| Kekuwatan Tensile |

≥48 |

Mpa |

50 |

| Elongation |

≥10 |

% |

11 |

| Kekuwatan Dampak |

≥10 |

Mpa |

11 |

| Thermal | |||

| Suhu Softening Vicat |

≥70 |

°C |

76.8 |

| Distortion temperature |

≥68 |

°C |

68 |

| Kimia | |||

| 35%±1% (v/v) HCI |

±4 |

g/ cm2 |

+2 |

| 30%±1% (v/v) H2SO4 |

±3 |

g/ cm2 |

+1 |

| 40%±1% (v/v) HNO3 |

±3 |

g/ cm2 |

+1 |

| 40%±1% (v/v) NaOH |

±3 |

g/ cm2 |

+1 |

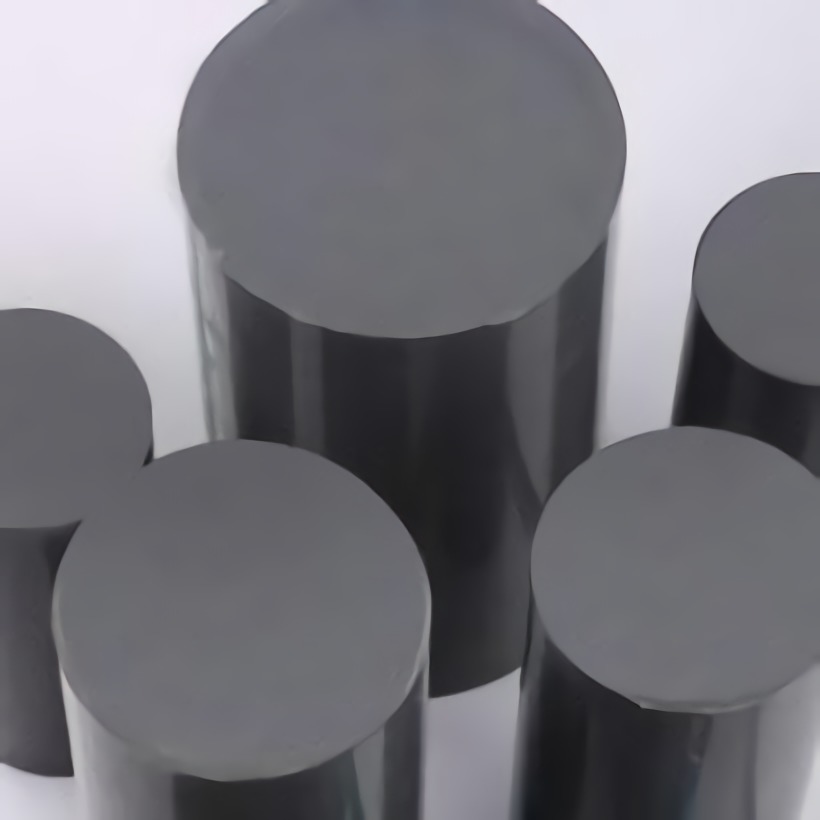

Deskripsi Produk

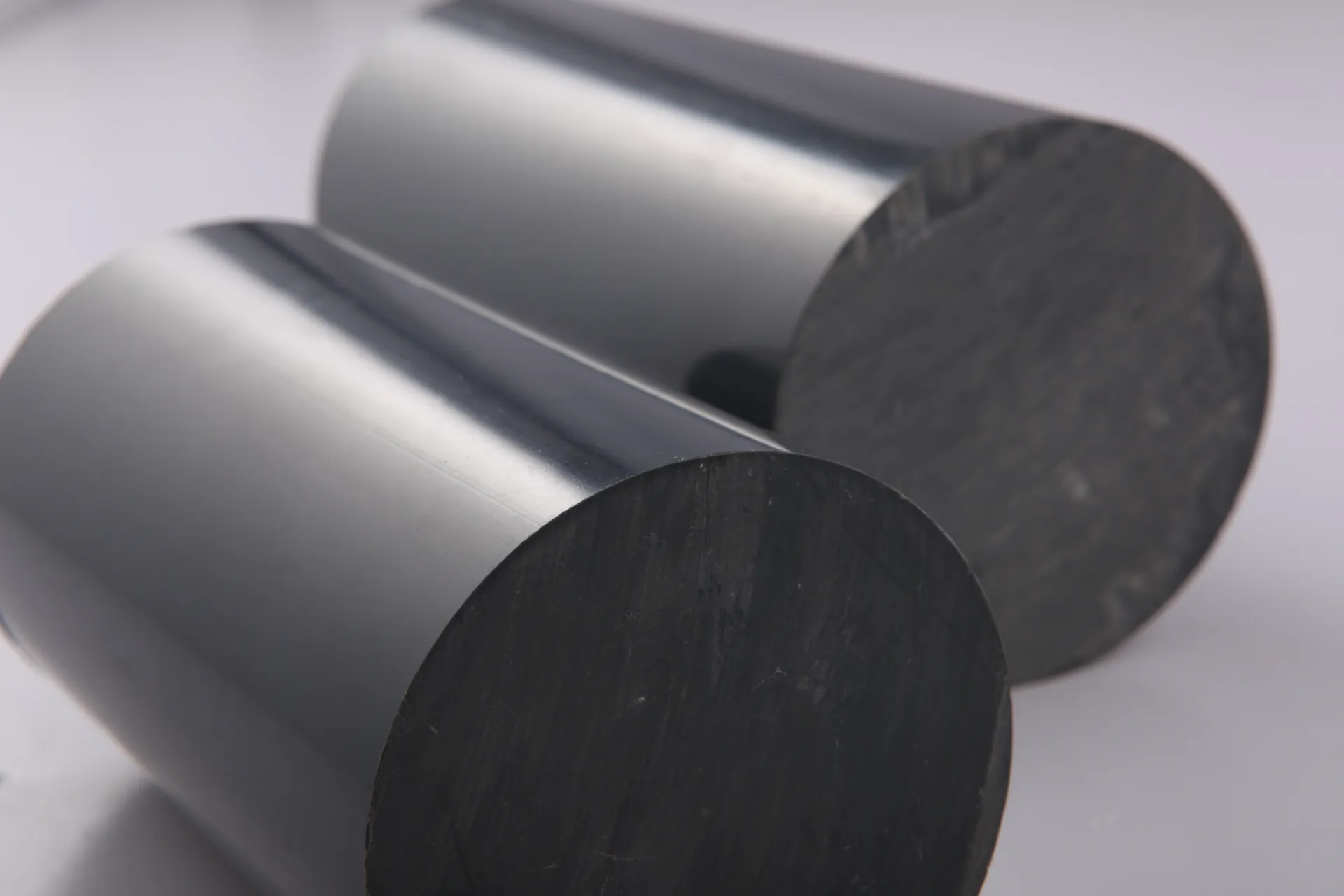

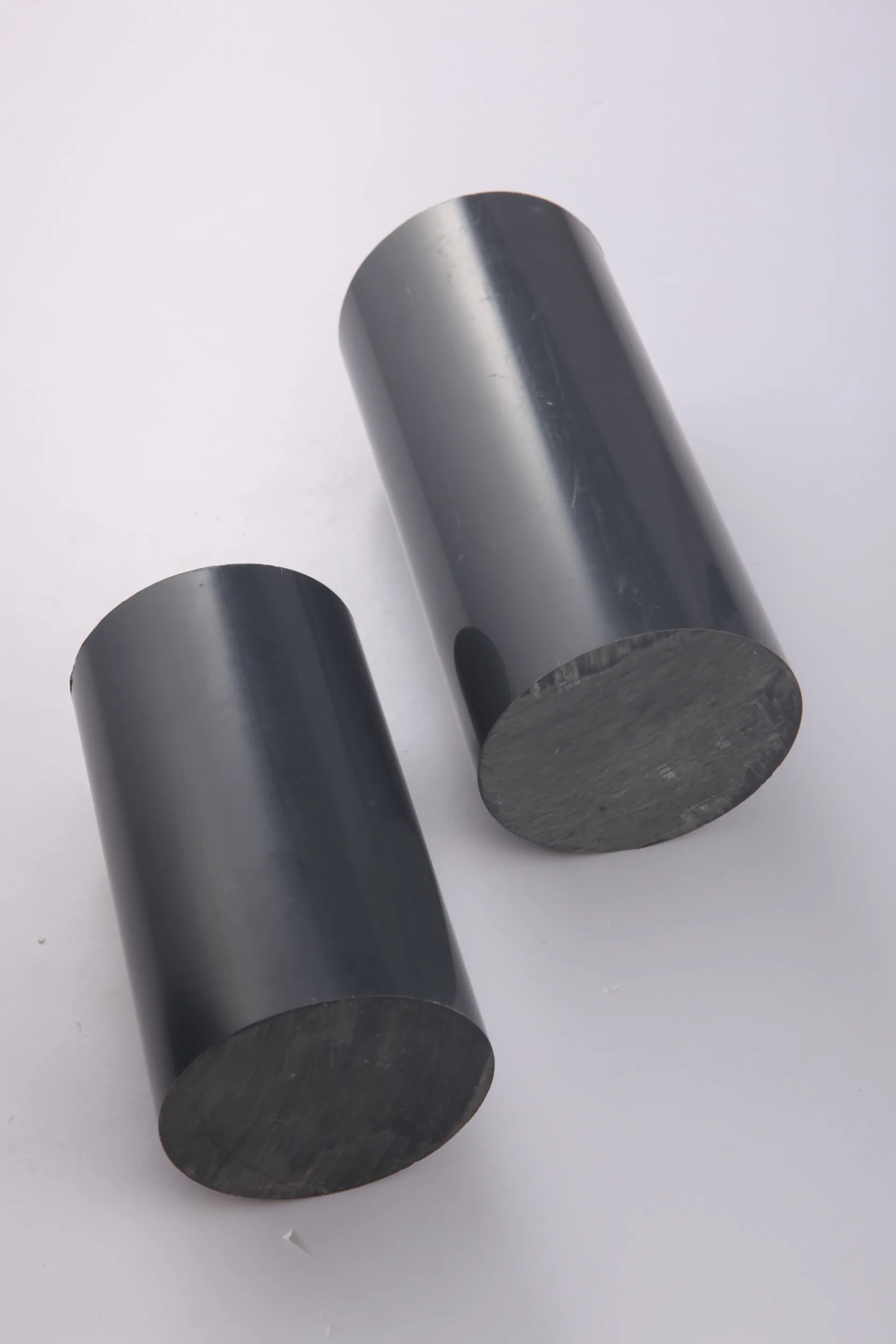

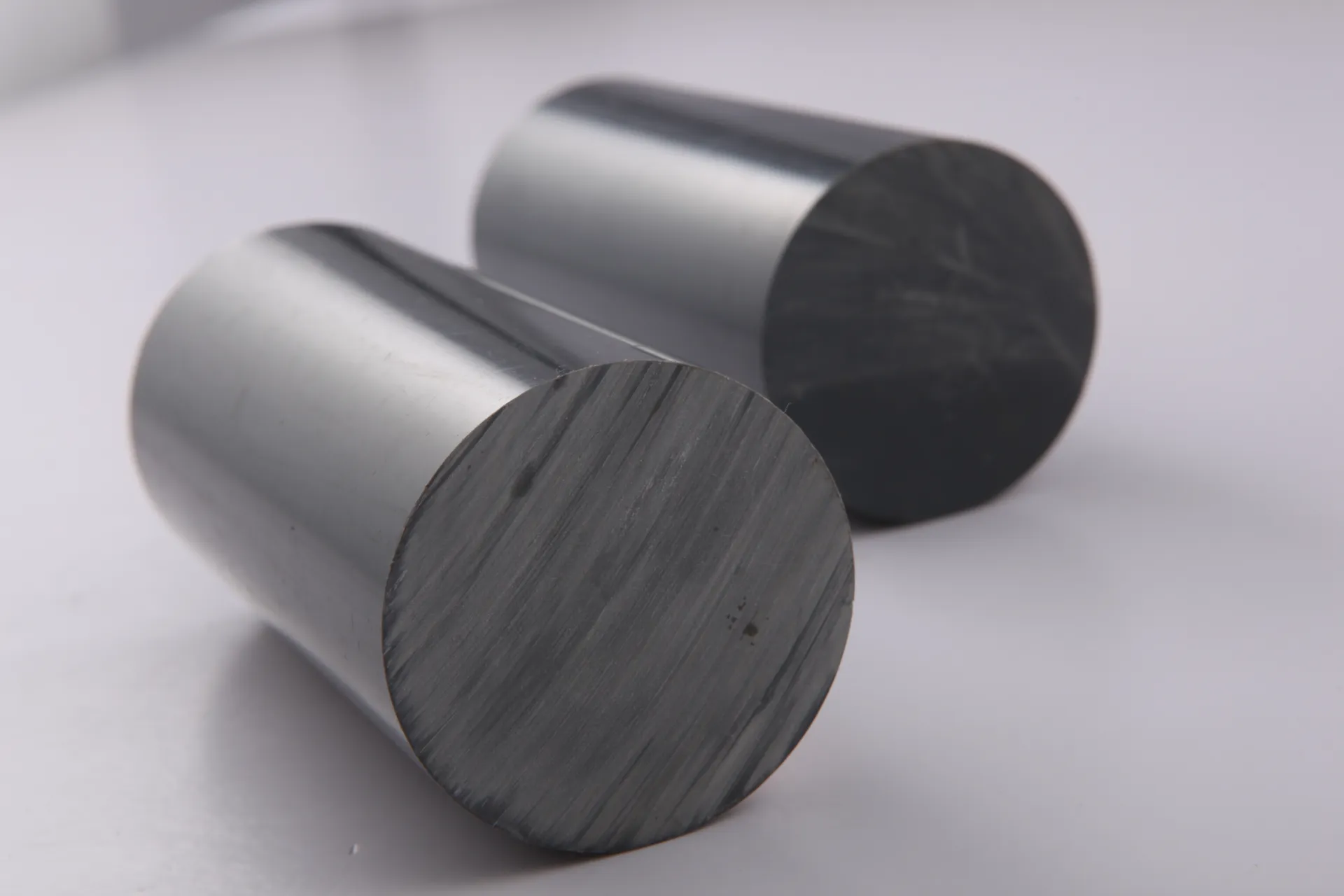

Rod bunder PVC digawe karo resin polivinil klorida(PVC), penstabil, pelumas, plasticizer, pengisi, modifier impact, pigmen lan aditif liyane. Iku karo apik kadhemen tahan, asam & alkali tahan, weldable lan apik anti-karat property. Kajaba iku, properti fisik luwih apik tinimbang karet lan bahan sing digulung liyane. Iki digunakake kanthi wiyar ing industri kimia lan galvanisasi. Kayata lapisan sel elektrolitik, segel insulasi listrik, mesin cuci punching dll.

Karakteristik

Rigidity dhuwur;

Low flammability;

Katon ayu;

Formability banget;

atose lumahing dhuwur;

Isolasi listrik sing bisa dipercaya;

Kinerja tahan gores sing apik banget,

Resistance kimia lan karat banget;

resistance impact lan resistance kanggo pelarut kimia;

kinerja pinunjul.

Sertifikat PVC bulat rod

ROHS.

R&D

Our company adopts environment-friendly raw materials. Strictly control the production process, from raw materials to the factory layer quality inspection.The experimental testing follows the international quality management and certification system to ensure the quality of products.

Perusahaan kita nyiyapake sawetara eksperimen independen, kanthi otomatisasi peralatan produksi sing dhuwur, saben taun kanggo nandur modal akeh dhuwit, introduksi bakat lan teknologi, nduweni pasukan riset ilmiah sing kuwat.

Aplikasi

PVC rod babak wis digunakake digunakake ing produksi asam sulfat, pangayoman lingkungan lan lenga, industri kimia, lan ing serat kimia, farmasi, kulit, dye, kayata industri Manufaktur uga wis nomer akeh aplikasi.