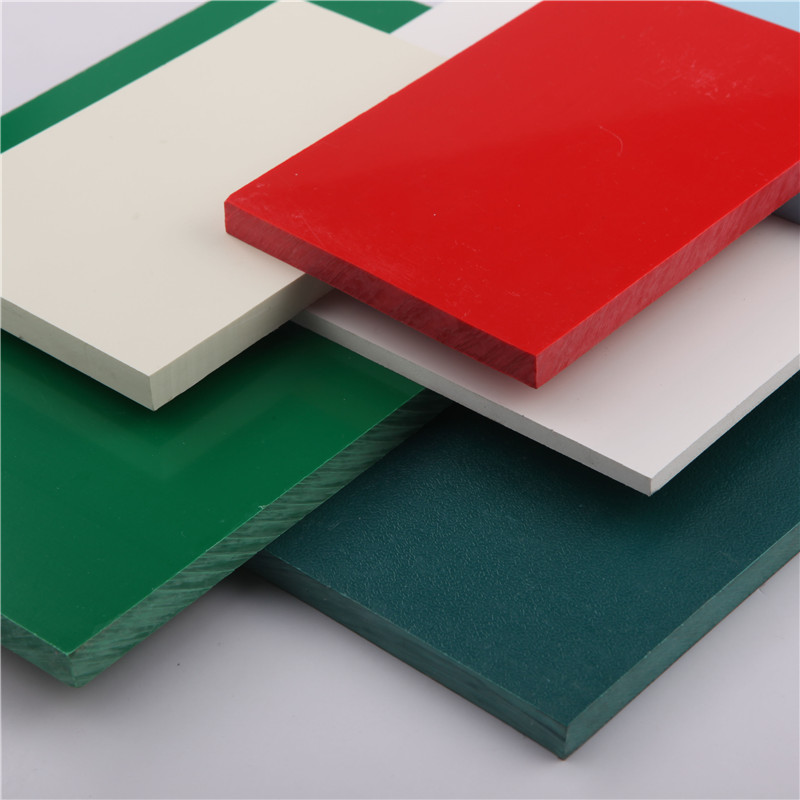

Cov ntaub ntawv qhia txog PVC rigid sheet UV stabilized:

|

Test Standard (GB/T 22789.1-2008) |

Chav tsev |

Tus nqi |

|

| Lub cev | |||

| Qhov ntom |

1.45~1.5 |

g/cm3 |

1.45 |

| Neeg kho tshuab | |||

| Tensile Strength (Length / Dav) |

≥45 |

Mpa |

52.9/48.9 |

| Elongation (Length / Dav) |

≥8 |

% |

29/32 |

| Notch Impact Strength (Length / Dav) |

≥5 |

KJ/㎡ |

7.83/7.57 |

| Charpy Unnotched Impact Strength0 ℃ -20 ℃ |

—– —– |

KJ/㎡ KJ/㎡ |

pendulum 4J Sample tsis tawg |

| Bending zog V = 2mm / min |

—– |

Mpa |

76.2 |

| Pob Indentation Hardness 358N (h: 0.118 ~ 0.138) |

—– |

N/m ㎡ |

221 |

| Kub | |||

| Vicat Softening Kub |

≥70 |

°C |

76.8 |

| Thaum tshav kub kub Shrinkage (Length / Breadth) |

-4~+4 |

% |

+1.9/-0.1 |

| Deflection kub nyob rau hauv load (Length / Breadth) |

—– |

°C |

69.5/69.7 |

| Tshuaj | |||

| 35% ± 1% (v/v) HCI 5h 60 ° C |

± 10 |

g/cm3 |

+5 |

| 30% ± 1% (v/v) H2SO4 5h 60 ° C |

± 8 |

g/cm3 |

+4 |

| 40% ± 1% (v/v) HNO3 5h 60 ° C |

± 8 |

g/cm3 |

+4 |

| 40% ± 1% (v/v) NaOH 5h 60 ° C |

± 5 |

g/cm3 |

+2 |

| Hluav taws xob | |||

| Volume Resistivity |

—– |

ohm · cm |

5.5 × 1013 |

Daim ntawv thov:

PVC rigid sheets UV stabilized yog dav siv nyob rau hauv dav dav thiab tshuaj industries, xws li Lab cov cuab yeej, Etching khoom, Semiconductor ua khoom, plating chim, dej tank, tshuaj storing tank, roj tank, storing tank rau brewing dej, kua qaub los yog alkali ntau lawm ntauwd , kua qaub los yog alkali ntxhua khaub ncaws, duab tsim cov cuab yeej; Kev lag luam hluav taws xob rau lub thawv roj teeb, electrometer phaj, electrolytic tank thiab ntau daim hlau rau hluav taws xob rwb thaiv tsev, kos npe rau kev tshaj tawm, phab ntsa cladding ntawm chaw ua hauj lwm thiab kev siv pej xeem, qhov rooj panels thiab lwm yam.

R & D:

1.Our tuam txhab txais ib puag ncig-phooj ywg raw cov ntaub ntawv. nruj me ntsis tswj cov txheej txheem ntau lawm, los ntawm raw cov ntaub ntawv mus rau lub Hoobkas txheej zoo soj ntsuam.Qhov kev sim ua raws li thoob ntiaj teb zoo tswj thiab ntawv pov thawj system los xyuas kom meej cov khoom zoo.

2.Our lub tuam txhab teeb tsa ib tug xov tooj ntawm kev ywj pheej thwmsim, nrog ib tug high degree ntawm automation ntawm cov khoom siv ntau lawm, txhua txhua xyoo los nqis peev nyiaj ntau, kev taw qhia txog kev txawj ntse thiab kev siv tshuab, muaj kev tshawb fawb muaj zog.