Aug . 26, 2025 04:20 Back to list

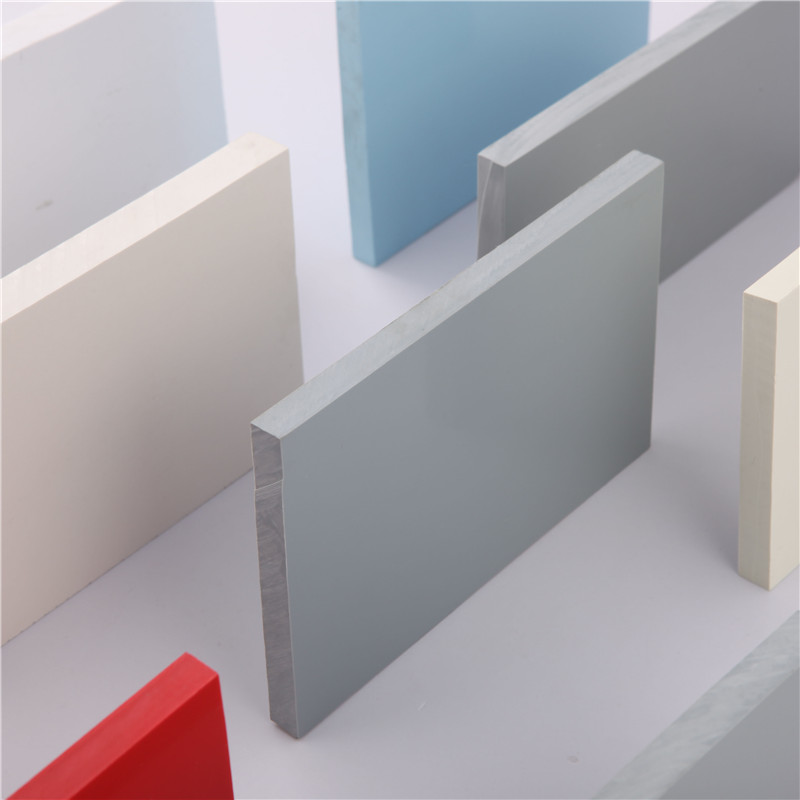

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

The Advanced Properties and Applications of PVC Rigid Sheet(glossy surface)

In the realm of advanced material solutions for industrial and commercial applications, the PVC Rigid Sheet(glossy surface) stands out as a highly versatile and performant product. Engineered for demanding environments, this material combines exceptional durability with a superior aesthetic finish, making it indispensable across a multitude of sectors. From critical infrastructure to high-end display solutions, its unique blend of mechanical, chemical, and electrical properties ensures reliable and cost-effective performance, directly addressing complex B2B requirements. Its non-porous, smooth surface enhances both hygiene and visual appeal, offering a robust alternative to traditional materials.

Current Industry Trends for Rigid PVC Sheets

The market for rigid PVC sheets, particularly those with a glossy surface finish, is experiencing dynamic growth driven by several key industry trends. Digitalization and automation in manufacturing processes are leading to higher precision and customization capabilities. There's a significant push towards sustainable materials and production methods, prompting manufacturers to optimize resource utilization and recyclability of PVC. Furthermore, the demand for enhanced aesthetic appeal combined with functional performance is growing, particularly in sectors like architectural cladding, cleanroom applications, and high-visibility retail displays. Innovations in UV stabilization and anti-scratch coatings are extending the service life and maintaining the pristine appearance of PVC Rigid Sheet(glossy surface) in outdoor or high-traffic environments. The convergence of these trends underscores the material's adaptability and continued relevance in an evolving industrial landscape.

Detailed Manufacturing Process Flow

The production of high-quality PVC Rigid Sheet(glossy surface) involves a meticulously controlled, multi-stage manufacturing process to ensure uniformity, structural integrity, and the desired surface finish. This typically begins with the precise compounding of raw materials, followed by either extrusion or calendering, culminating in surface treatment and rigorous quality control.

1. Raw Material Preparation

High-grade PVC resin is blended with stabilizers (e.g., calcium-zinc or tin-based), lubricants, processing aids, and pigments. The selection of these additives is critical for achieving optimal thermal stability, processability, and the desired final properties and gloss level.

2. Compounding & Homogenization

The blended mixture is subjected to high-speed mixing to ensure a homogeneous dispersion of all components, forming a dry blend or pelletized compound. This step prevents segregation and ensures consistent material flow and product quality.

3. Calendering or Extrusion

For high-volume, high-quality sheets, calendering is often preferred. The compound is fed into a series of heated, counter-rotating rollers that progressively press and stretch the material into a continuous sheet of uniform thickness. Extrusion involves melting the compound and forcing it through a die to form the sheet.

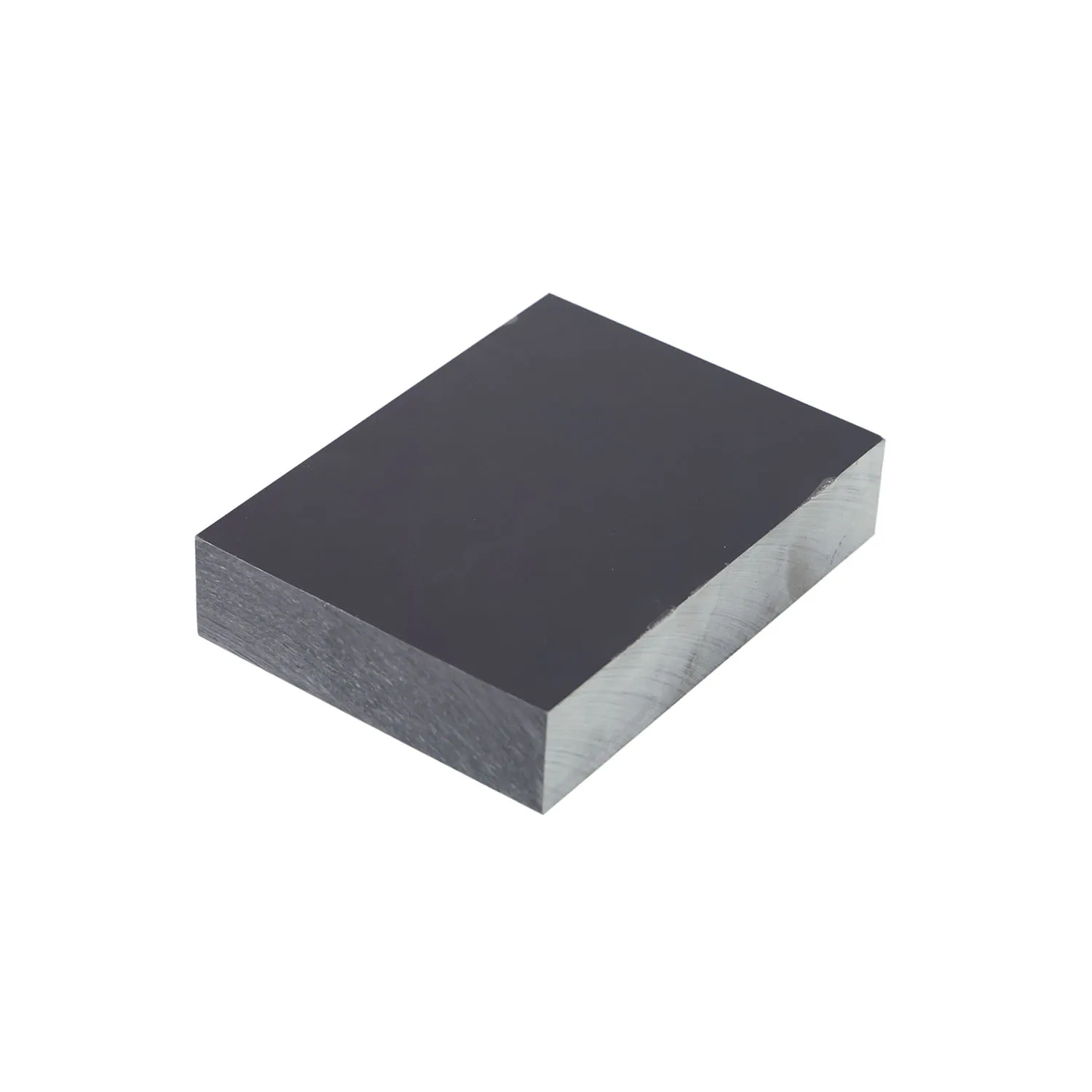

4. Cooling & Gloss Application

The hot sheet passes through cooling rolls to stabilize its dimensions. The glossy surface is achieved either directly during the calendering process with polished rolls or subsequently through a lamination step with a high-gloss film, ensuring a durable and reflective finish.

5. Trimming & Cutting

The cooled and finished sheet is then trimmed to precise widths and cut into specified lengths using automated cutting machinery, minimizing material waste and ensuring dimensional accuracy.

6. Quality Control & Testing

Each batch undergoes rigorous testing to meet international standards such as ISO 9001 for quality management and specific material standards (e.g., ASTM D1784 for PVC compounds). Tests include dimensional stability, tensile strength, impact resistance, chemical resistance, fire rating (UL 94 V-0), and surface gloss measurement.

The typical service life of a PVC Rigid Sheet(glossy surface), when properly applied and maintained in its target industries like petrochemical, metallurgy, and water supply & drainage, can exceed 20 years, demonstrating exceptional longevity. Its resistance to various corrosive chemicals and minimal water absorption ensures energy saving in process lines by preventing degradation and leaks.

Technical Specifications and Parameters

Understanding the technical specifications of PVC Rigid Sheet(glossy surface) is paramount for engineers and procurement specialists to ensure optimal material selection for specific applications. Our sheets are manufactured to precise standards, ensuring consistent performance and compliance with industry benchmarks. Below is a comprehensive table detailing key physical, mechanical, and thermal properties.

| Property | Test Method | Unit | Typical Value |

|---|---|---|---|

| Density | ISO 1183 | g/cm³ | 1.38 - 1.45 |

| Tensile Strength | ISO 527 | MPa | > 50 |

| Elongation at Break | ISO 527 | % | > 15 |

| Notched Izod Impact Strength (23°C) | ISO 180/A | kJ/m² | > 5 |

| Vicat Softening Point (VST/B/50) | ISO 306 | °C | > 78 |

| Thermal Conductivity | DIN 52612 | W/(m·K) | 0.16 |

| Water Absorption (24h) | ISO 62 | % | < 0.1 |

| Dielectric Strength | IEC 243 | kV/mm | > 35 |

| Fire Rating (Oxygen Index) | ISO 4589 | % | > 40 (Self-extinguishing) |

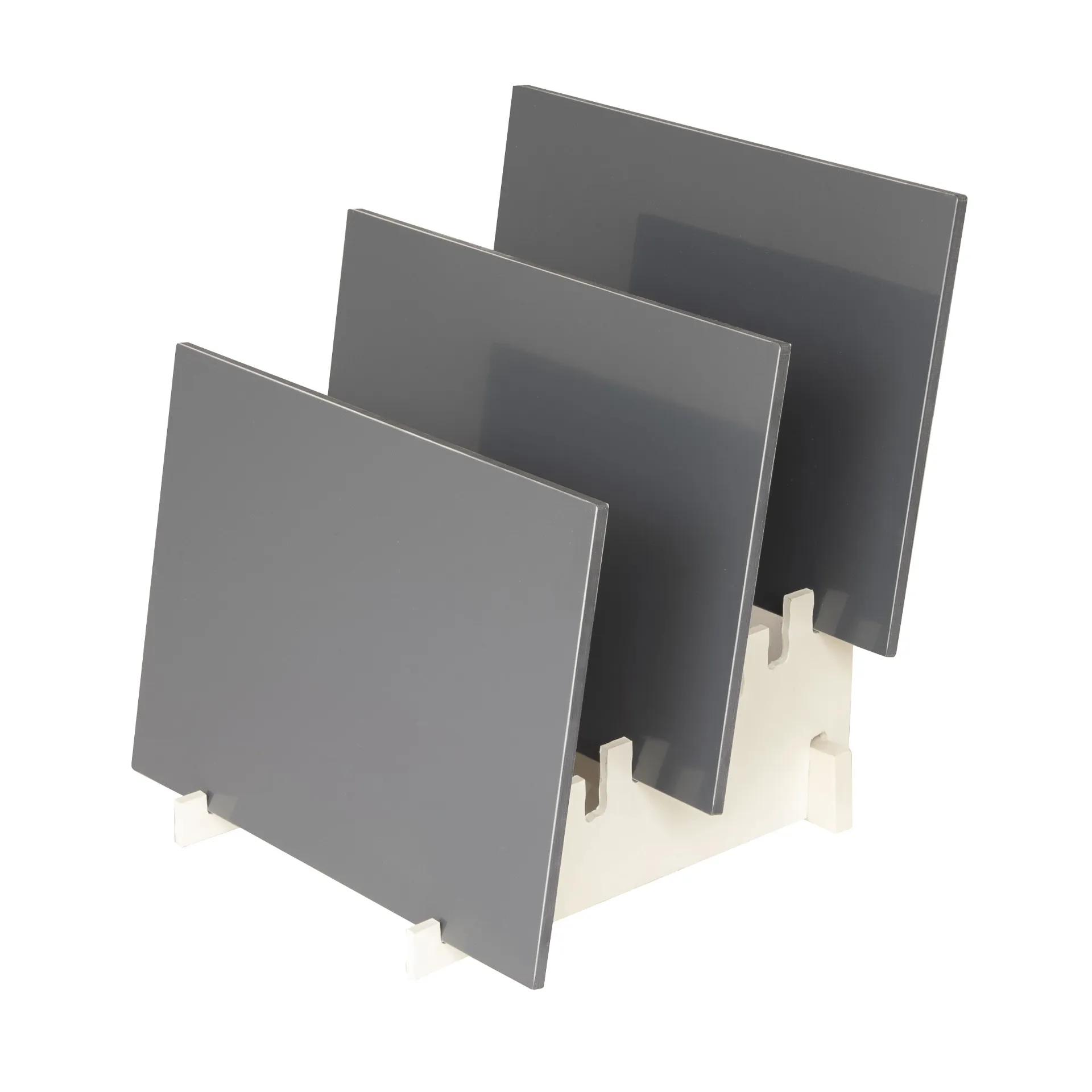

| Surface Gloss (60° Gardner) | ASTM D523 | GU | > 85 |

These parameters highlight the robust nature and engineering suitability of our PVC Rigid Sheet(glossy surface) for critical applications where material stability, chemical resistance, and electrical insulation are key performance indicators. Our products consistently exceed these benchmarks, providing superior value and long-term reliability.

Diverse Application Scenarios

The versatility of PVC Rigid Sheet(glossy surface) extends across a broad spectrum of industries, driven by its intrinsic properties such as chemical inertness, high strength-to-weight ratio, and excellent aesthetic appeal.

- Chemical Processing Industry: Due to its exceptional resistance to acids, alkalis, and many organic solvents, glossy PVC rigid sheets are widely used for tank linings, fume hoods, ductwork, and process equipment in chemical plants. Its non-reactive surface ensures the purity of processed chemicals.

- Water Treatment & Purification: Ideal for wet environments, these sheets are employed in constructing cleanroom walls, wastewater treatment components, and potable water storage tank covers. Their low water absorption and hygienic surface prevent bacterial growth, crucial for public health applications.

- Electronics & Electrical: With high dielectric strength and insulating properties, glossy PVC rigid sheets are excellent for electrical control panels, insulating spacers, and components where electrical isolation is critical.

- Construction & Architecture: Used for wall cladding in hospitals and laboratories, cleanroom partitioning, durable interior finishes, and specialized roofing components. The glossy surface contributes to easy cleaning and a modern aesthetic.

- Signage & Display: Its excellent printability, rigidity, and high-gloss finish make it a preferred material for high-impact point-of-sale displays, exhibition stands, and long-lasting outdoor signage. The glossy surface enhances visual vibrancy and durability.

- Food & Beverage Processing: Approved for contact with food in many regions (subject to specific formulations and regulatory compliance), its smooth, non-absorbent surface is ideal for hygienic environments such as food preparation areas and storage partitions.

Technical Advantages and Benefits

The technical advantages of employing PVC Rigid Sheet(glossy surface) in industrial applications are manifold, offering significant operational benefits and long-term cost savings.

- Superior Chemical Resistance: Unaffected by a wide array of acids, alkalis, and other corrosive agents, ensuring longevity and material integrity in harsh chemical environments. This significantly reduces maintenance and replacement costs.

- Excellent Dielectric Properties: Provides robust electrical insulation, making it a safe and reliable choice for electrical enclosures, panel boards, and protective coverings in high-voltage applications.

- High Strength and Rigidity: Despite its light weight compared to metals, it offers exceptional structural integrity and impact resistance, allowing for durable installations even in physically demanding settings.

- Low Flammability & Self-Extinguishing: PVC has an inherently high oxygen index, meaning it requires a significant amount of oxygen to burn, and is self-extinguishing once the flame source is removed, enhancing safety in critical infrastructure.

- Dimensional Stability: Maintains its shape and size across varying temperatures and humidity levels, crucial for precision applications where structural integrity cannot be compromised.

- Exceptional Surface Finish: The glossy surface is not only aesthetically pleasing but also highly practical. It is easy to clean, resistant to staining, and does not support bacterial growth, making it ideal for hygienic environments like laboratories and food processing plants.

- Ease of Fabrication: Can be easily cut, routed, welded, and thermoformed using standard equipment, offering flexibility in design and installation, thereby reducing fabrication time and costs.

These advantages position PVC Rigid Sheet(glossy surface) as a preferred material solution that delivers both performance excellence and economic efficiency for discerning B2B clients.

Vendor Comparison: Lida Plastic vs. Competitors

Choosing the right supplier for PVC Rigid Sheet(glossy surface) is critical for project success. While several manufacturers offer similar products, key differentiators in quality, customization, lead time, and support can significantly impact project outcomes. Below is a comparison highlighting our commitment to excellence.

| Feature/Metric | Lida Plastic Industry Co., Ltd. | Competitor A | Competitor B |

|---|---|---|---|

| Product Certifications | ISO 9001, RoHS, REACH, CE | ISO 9001 | ISO 9001, some regional |

| Customization Capabilities | Full customization (color, size, thickness, additives, finishes) | Limited (standard sizes/colors) | Moderate (some custom sizes) |

| Lead Time (Standard Orders) | 5-10 business days | 10-15 business days | 7-12 business days |

| Quality Consistency | Excellent (rigorous QC, advanced manufacturing) | Good (occasional variations) | Good (standard adherence) |

| After-Sales Support | Dedicated technical support, 24/7 online assistance | Standard office hours support | Email support |

| Technical Expertise | Specialized B2B team, R&D for bespoke solutions | General product knowledge | Basic application guidance |

Customized Solutions

Recognizing that every industrial application has unique demands, we specialize in providing highly customized PVC Rigid Sheet(glossy surface) solutions. Our engineering team collaborates closely with clients to develop materials that precisely match their specific operational and environmental requirements.

- Tailored Dimensions: Beyond standard sizes, we offer precision cutting and shaping to virtually any dimension, minimizing waste and optimizing fabrication efficiency for our clients.

- Specific Thicknesses: From ultra-thin films for specialized applications to robust thick sheets requiring enhanced rigidity and impact resistance, our manufacturing process allows for a wide range of thickness customization.

- Color Matching: We can match specific RAL or Pantone colors to align with corporate branding or functional coding requirements, ensuring aesthetic consistency across projects.

- Enhanced Properties: Additives can be incorporated during compounding to boost specific characteristics such as UV resistance for outdoor applications, anti-static properties for electronics, improved impact modifiers for high-stress environments, or enhanced flame retardancy.

- Surface Finishes: While our focus is glossy, we can also provide specialized surface treatments for textures, anti-glare, or anti-scratch properties, depending on the application's unique functional and visual needs.

Our agile manufacturing capabilities and in-depth material science expertise ensure that your customized PVC Rigid Sheet(glossy surface) solution will perform flawlessly, exactly as intended.

Application Case Studies

Case Study 1: Chemical Tank Lining for a Petrochemical Plant

Challenge: A major petrochemical facility faced recurring issues with the corrosion of steel storage tanks holding concentrated sulfuric acid (98%). Traditional coatings failed within 1-2 years, leading to costly downtime and safety concerns.

Solution: We supplied custom-fabricated PVC Rigid Sheet(glossy surface) for internal lining of the tanks. The sheets were heat-welded on-site to create a seamless, impermeable barrier. The material's exceptional chemical inertness to sulfuric acid was a critical factor.

Results: After five years of continuous operation, the PVC lining showed no signs of degradation, significantly exceeding the service life of previous solutions. The glossy surface facilitated inspection and cleaning. This led to a 70% reduction in maintenance costs associated with tank corrosion and zero unscheduled downtimes related to material failure, demonstrating the product's robust corrosion resistance in severe environments.

Case Study 2: Cleanroom Partitioning for a Pharmaceutical Manufacturer

Challenge: A pharmaceutical company needed to construct new ISO Class 7 cleanrooms for sterile manufacturing. Key requirements included materials that were easy to clean, non-shedding, resistant to common disinfectants, and aesthetically pleasing.

Solution: We provided custom-sized PVC Rigid Sheet(glossy surface) in a pure white finish for wall and ceiling panels. The sheets were lightweight, facilitating rapid installation, and their smooth, glossy surface allowed for efficient sanitization protocols and minimized particle accumulation.

Results: The cleanrooms met all regulatory compliance standards with respect to particle counts and microbial control. The glossy PVC surface proved highly resistant to repeated cleaning with harsh chemical sanitizers, maintaining its pristine appearance over time. Installation time was reduced by 30% compared to traditional gypsum-based cleanroom constructions, offering significant project cost savings and operational readiness.

Frequently Asked Questions (FAQ)

Q: Is PVC Rigid Sheet(glossy surface) suitable for outdoor use?

A: Yes, with appropriate UV stabilizers incorporated during manufacturing, our glossy PVC rigid sheets can perform exceptionally well in outdoor environments, resisting discoloration and degradation from sunlight exposure. We recommend specifying UV-stabilized grades for exterior applications.

Q: How does the glossy surface affect its chemical resistance?

A: The glossy surface is integral to the PVC material itself, or a highly durable lamination, and does not diminish its inherent chemical resistance. In fact, the smooth, non-porous nature of the glossy finish can enhance resistance to chemical penetration and make cleaning easier, further contributing to its longevity in corrosive settings.

Q: Can these sheets be thermoformed?

A: Absolutely. PVC Rigid Sheet(glossy surface) has excellent thermoforming properties, allowing it to be heated and shaped into complex geometries without losing its structural integrity or glossy finish. This makes it ideal for custom fabrication and design flexibility.

Q: What is the typical lead time for custom orders?

A: For custom orders, the lead time typically ranges from 10 to 20 business days, depending on the complexity, volume, and specific customization requirements. We maintain a flexible manufacturing schedule to accommodate urgent project deadlines where possible. Our team will provide an accurate lead time estimate upon order confirmation.

Lead Time & Fulfillment

We understand the critical importance of timely delivery in B2B operations. Our robust supply chain and efficient production processes enable us to offer competitive lead times for PVC Rigid Sheet(glossy surface).

- Standard Orders: Typically fulfilled within 5-10 business days from order confirmation, depending on stock availability and volume.

- Custom & Large Volume Orders: Lead times range from 10-20 business days, subject to material sourcing and production schedule. Our sales team provides precise estimates upon request.

- Shipping: We partner with reliable logistics providers to ensure safe and efficient global delivery. Express shipping options are available for urgent requirements.

Warranty Commitments

Our commitment to quality is backed by a comprehensive warranty. We guarantee that all PVC Rigid Sheet(glossy surface) products are free from manufacturing defects and perform according to specified technical parameters for a period of 5 years from the date of purchase, under normal use and recommended installation guidelines. This warranty covers material integrity and surface finish against premature degradation. Specific project warranties for extended periods can be negotiated for large-scale industrial applications.

Customer Support Information

Our dedicated customer support team is available to assist with all your inquiries, from technical specifications and product selection to order tracking and after-sales service.

- Technical Assistance: Our team of engineers and material scientists offers expert guidance on product suitability, installation, and application challenges.

- Sales & Inquiries: For new orders, quotations, and product information, please contact our sales department.

- After-Sales Service: Any post-delivery issues, warranty claims, or feedback are handled promptly and professionally to ensure client satisfaction.

- Contact Details:

- Email: sales@lidaplastic.com

- Phone: +86-XXX-XXXX-XXXX (Available during business hours)

- Website: www.lidaplastic.com

References and Citations

- ASTM D1784 - Standard Specification for Rigid Poly(Vinyl Chloride) (PVC) Compounds and Chlorinated Poly(Vinyl Chloride) (CPVC) Compounds.

- ISO 9001:2015 - Quality management systems — Requirements. International Organization for Standardization.

- UL 94 - Standard for Safety of Flammability of Plastic Materials for Parts in Devices and Appliances Testing. Underwriters Laboratories.

- Polymer Handbook, 4th Edition. Edited by J. Brandrup, E.H. Immergut, E.A. Grulke, A. Abe, D.R. Bloch. John Wiley & Sons, Inc., 1999.

- The Engineering Properties of Plastics, 2nd Edition. By R. W. Hertzberg, J. A. Manson, M. D. Galli. ASM International, 1999.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025