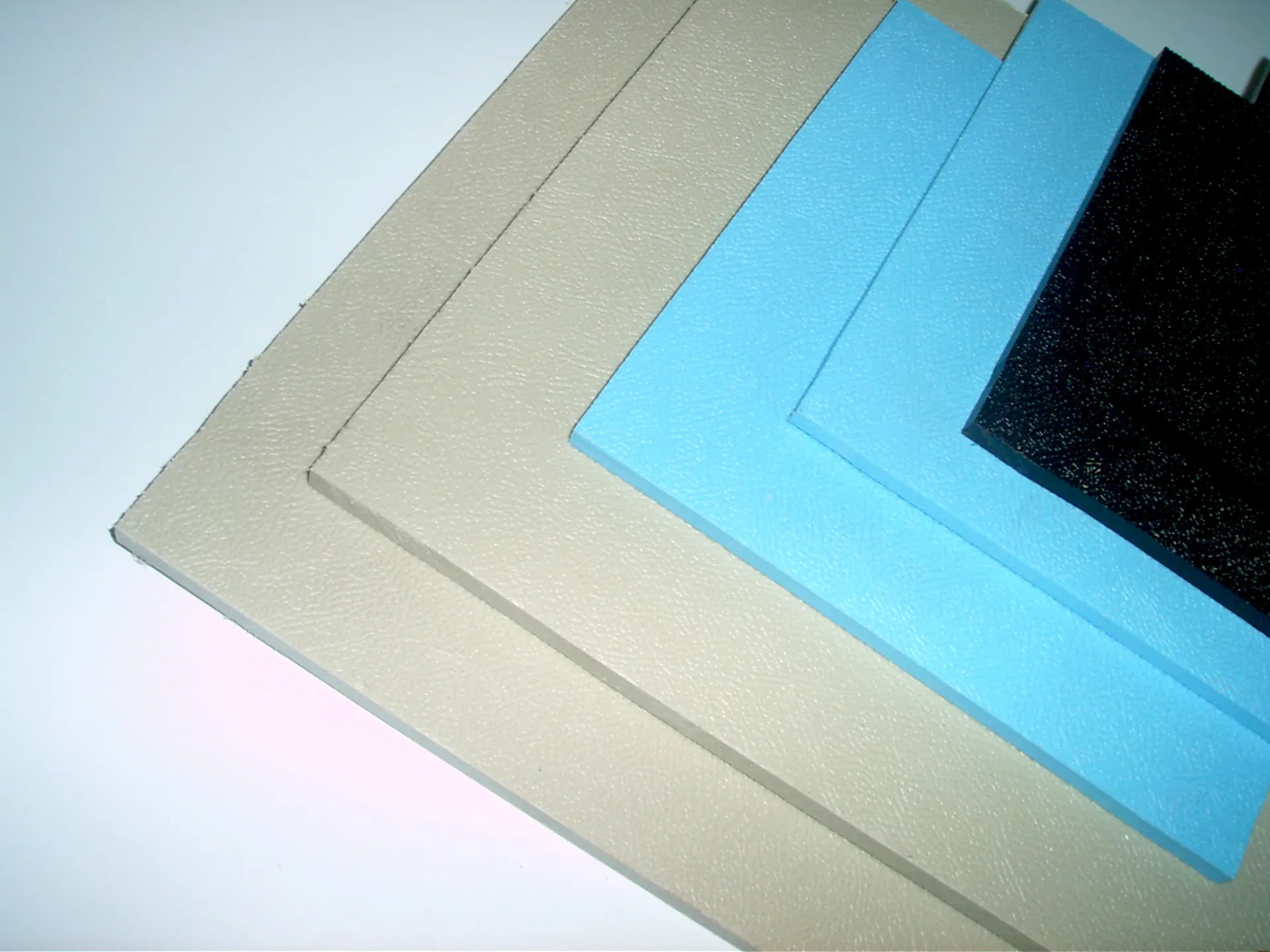

Kenyelletso ea sehlahisoa

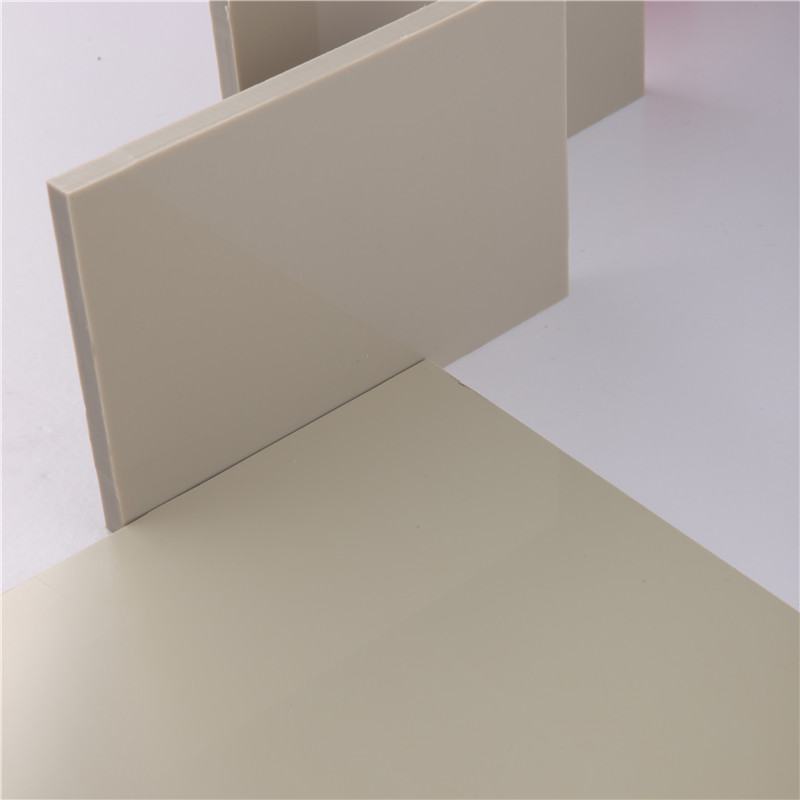

PPH is a kind of homopolymer polypropylene with high molecular weight and low melting finger. The material has been modified by β to have uniform and fine Beta crystal structure, which makes it not only have excellent chemical resistance, high temperature resistance and good creep resistance, but also have excellent impact resistance at low temperature.

Ho ea ka litšoaneleho tsa thepa ea PPH, poleiti ea PPH e entsoe ka thepa e thibelang kutu e sebelisoang haholo ho ntšitsoeng ha lik'hemik'hale, metallurgy le lisebelisoa tsa elektroniki le likarolo tse ling. Tanka ea ho khetha ea PPH le tanka ea electrolytic, ka bobeli e boloka chelete ebile e tšoarella, e fokotsa tlhokomelo ea lisebelisoa, 'me e lelefatsa bophelo ba ts'ebeletso, ka ts'ebetso e phahameng.

Technical Data Sheet of PPH sheet

|

Test Standard (GB/T) |

Yuniti |

Boleng bo Tlwaelehileng |

|

| Ea nama | |||

| Botenya |

0.90-0.93 |

g/cm3 |

0.915 |

| Mechini | |||

| Tensile Strength (Bolelele/Bophara) |

≥25 |

Mpa |

29.8/27.6 |

| Notch Impact Strength (Bolelele/Bophara) |

≥8 |

KJ/㎡ |

18.8/16.6 |

| Matla a Kobehang |

—– |

Mpa |

39.9 |

| Matla a Khatellang |

—– |

Mpa |

38.6 |

| Mocheso | |||

| Vicat Softening Temperature |

≥140 |

°C |

154 |

| Hear Shrinkage140°C/150min(Length/Breadth) |

-3~+3 |

% |

-0.41/+0.41 |

| Lik'hemik'hale | |||

| 35% HCI |

±1.0 |

g/ cm2 |

-0.12 |

| 30% H2SO4 |

±1.0 |

g/ cm2 |

-0.08 |

| 40% HNO3 |

±1.0 |

g/ cm2 |

-0.02 |

| 40% NaOH |

±1.0 |

g/ cm2 |

-0.08 |

R&D

1.Our company adopts environment-friendly raw materials.Strictly control the production process, from raw materials to the factory layer quality inspection.The

experimental testing follows the international quality management and certification

system to ensure the quality of products.

2.Our company set up a number of independent experiments, with a high degree of

automation of the production equipment, every year to invest a lot of money, the

introduction of talent and technology, has a strong scientific research force.