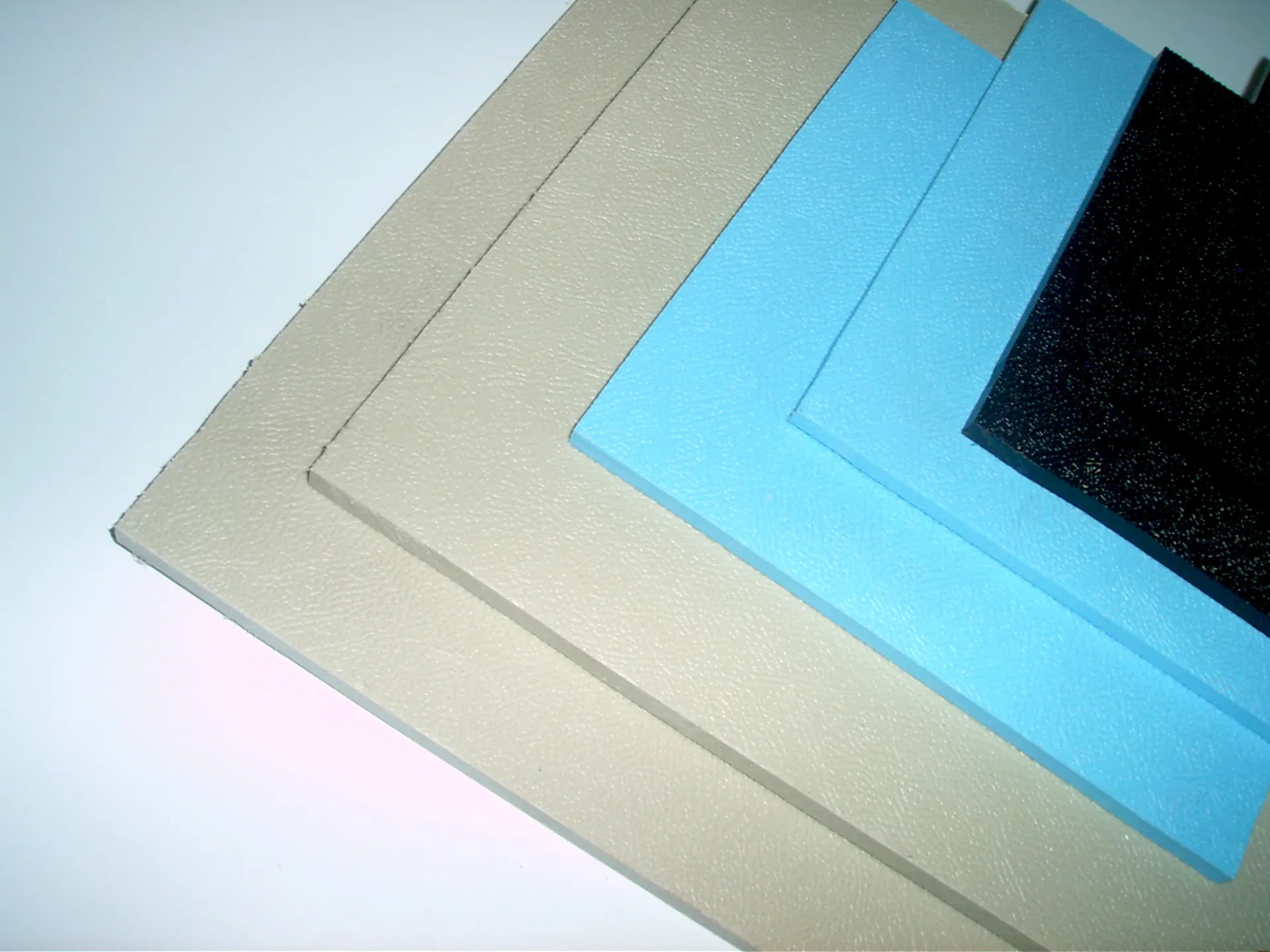

Ntinye ngwaahịa

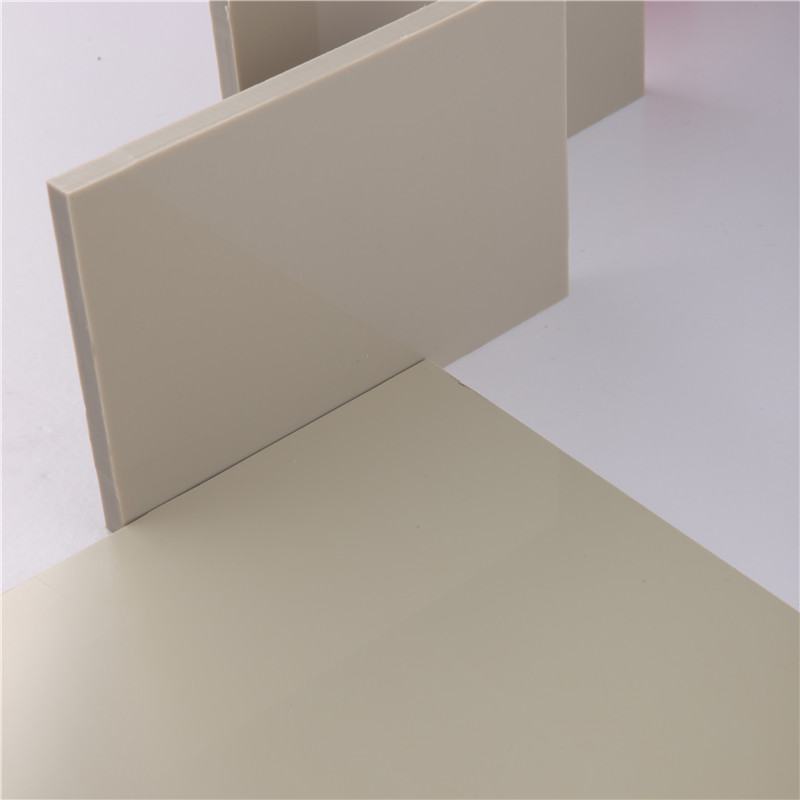

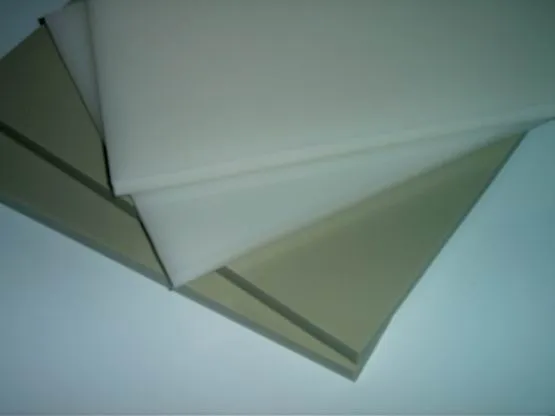

PPH is a kind of homopolymer polypropylene with high molecular weight and low melting finger. The material has been modified by β to have uniform and fine Beta crystal structure, which makes it not only have excellent chemical resistance, high temperature resistance and good creep resistance, but also have excellent impact resistance at low temperature.

Dabere na njirimara nke ihe PPH, a na-eme efere PPH ka ọ bụrụ akụrụngwa na-eguzogide corrosion nke a na-ejikarị na mmịpụta kemịkalụ, ọla na elektrọnik na mpaghara ndị ọzọ. PPH pickling tank na electrolytic tank, ma nke akụ na ụba ma na-adịgide adịgide, na-ebelata mmezi akụrụngwa, na ịgbatị ndụ ọrụ, na-arụ ọrụ dị elu.

Technical Data Sheet of PPH sheet

|

Test Standard (GB/T) |

Nkeji |

Uru a na-ahụkarị |

|

| Anụ ahụ | |||

| Njupụta |

0.90-0.93 |

g/cm3 |

0.915 |

| Mechanical | |||

| Ike Tensile ( Ogologo/ Ogologo) |

≥25 |

Mpa |

29.8/27.6 |

| Ike Mmetụta Notch ( Ogologo/ Ogologo) |

≥8 |

KJ/㎡ |

18.8/16.6 |

| Na-ehulata Ike |

—– |

Mpa |

39.9 |

| Ike mkpakọ |

—– |

Mpa |

38.6 |

| Thermal | |||

| Okpomọkụ na-eme ka Vicat dị nro |

≥140 |

Celsius C |

154 |

| Hear Shrinkage140°C/150min(Length/Breadth) |

-3~+3 |

% |

-0.41/+0.41 |

| Chemical | |||

| 35% HCI |

±1.0 |

g/ cm2 |

-0.12 |

| 30% H2SO4 |

±1.0 |

g/ cm2 |

-0.08 |

| 40% HNO3 |

±1.0 |

g/ cm2 |

-0.02 |

| 40% NaOH |

±1.0 |

g/ cm2 |

-0.08 |

R&D

1.Our company adopts environment-friendly raw materials.Strictly control the production process, from raw materials to the factory layer quality inspection.The

experimental testing follows the international quality management and certification

system to ensure the quality of products.

2.Our company set up a number of independent experiments, with a high degree of

automation of the production equipment, every year to invest a lot of money, the

introduction of talent and technology, has a strong scientific research force.