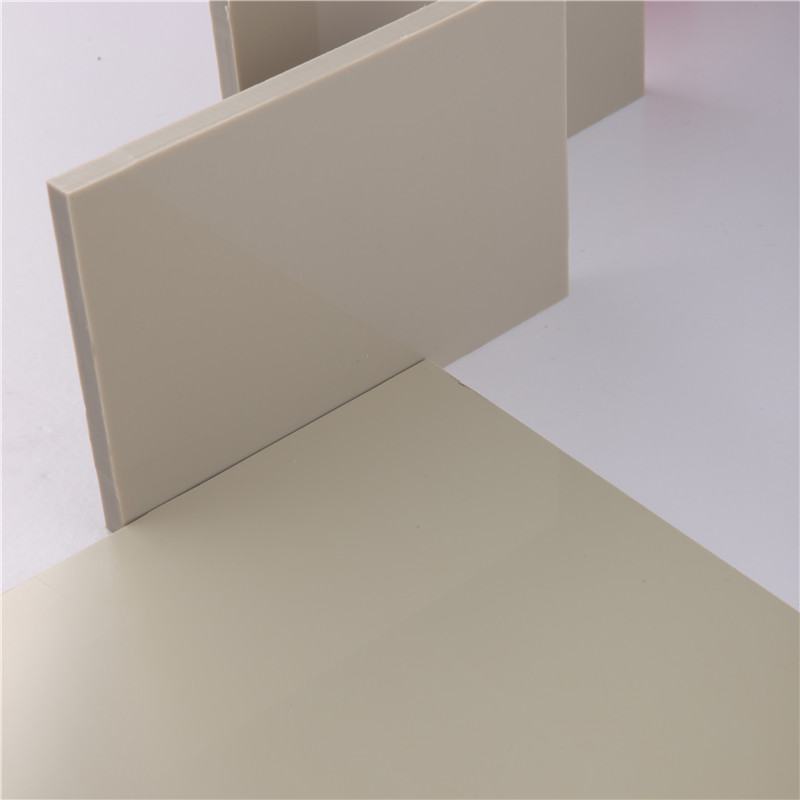

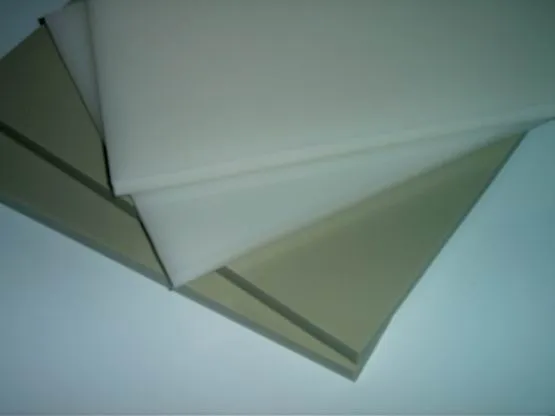

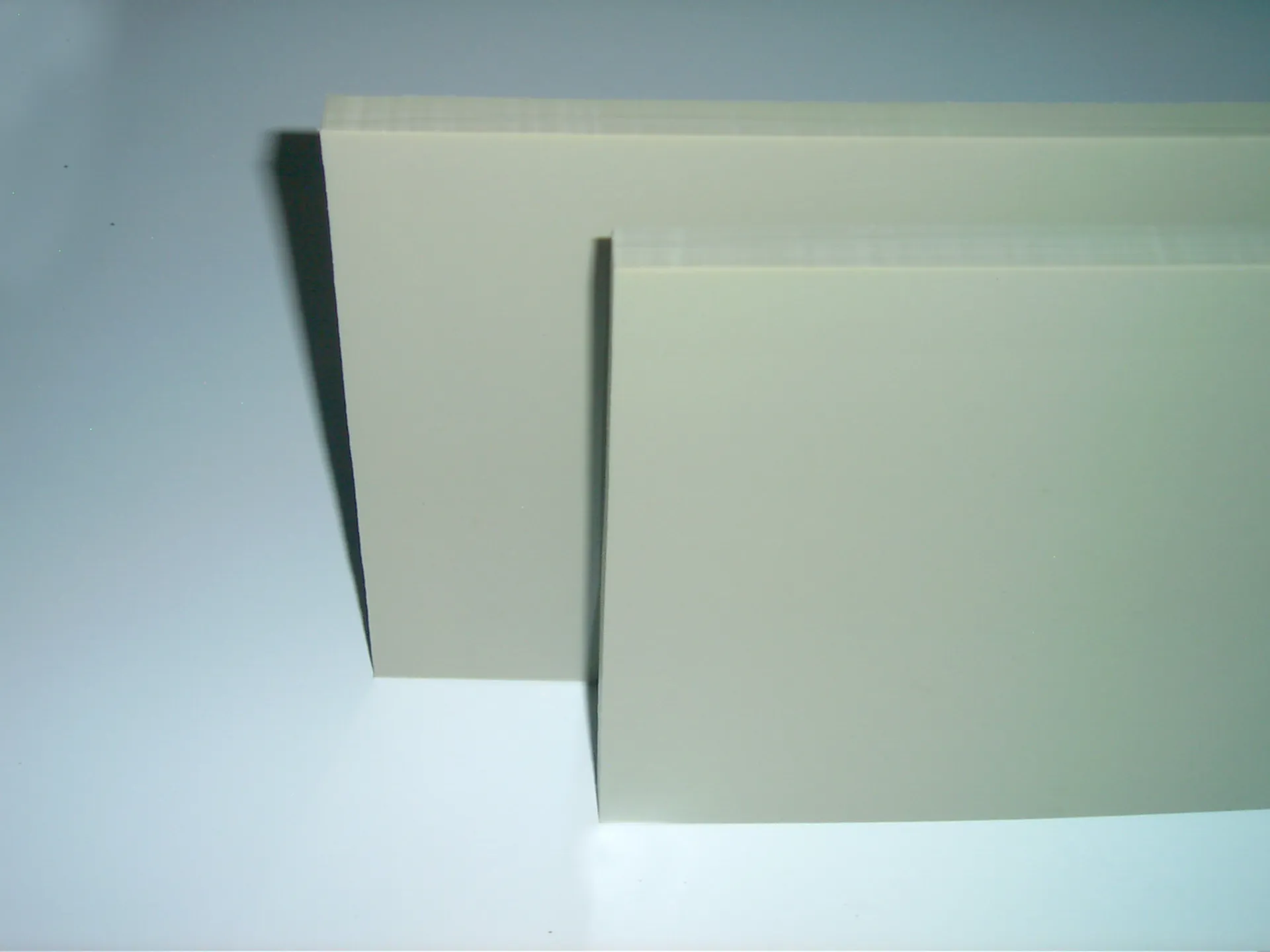

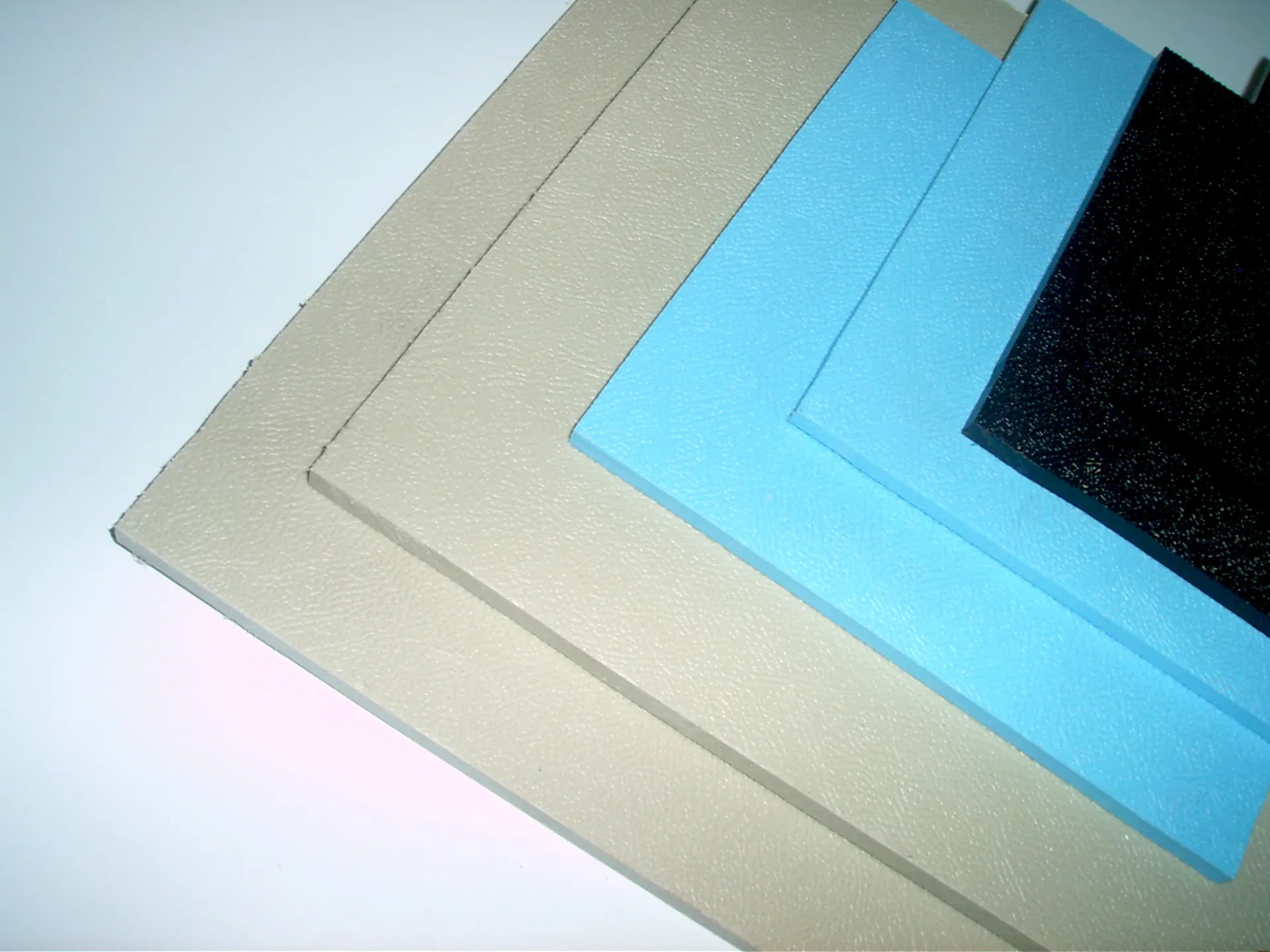

Khoom taw qhia

PPH is a kind of homopolymer polypropylene with high molecular weight and low melting finger. The material has been modified by β to have uniform and fine Beta crystal structure, which makes it not only have excellent chemical resistance, high temperature resistance and good creep resistance, but also have excellent impact resistance at low temperature.

Raws li cov yam ntxwv ntawm cov khoom siv PPH, PPH phaj yog tsim los rau hauv cov khoom siv tiv thaiv corrosion, dav siv hauv kev rho tawm tshuaj, metallurgy thiab electronics thiab lwm yam kev lag luam. PPH pickling tank thiab electrolytic tank, ob qho tib si kev lag luam thiab ruaj khov, txo cov khoom siv tu, thiab ncua kev pab cuam lub neej, nrog kev ua tau zoo dua.

Technical Data Sheet of PPH sheet

|

Test Standard (GB/T) |

Chav tsev |

Tus nqi |

|

| Lub cev | |||

| Qhov ntom |

0.90-0.93 |

g/cm3 |

0.915 |

| Neeg kho tshuab | |||

| Tensile Strength (Length / Dav) |

≥25 |

Mpa |

29.8/27.6 |

| Notch Impact Strength (Length / Dav) |

≥8 |

KJ/㎡ |

18.8/16.6 |

| Khoov zog |

—– |

Mpa |

39.9 |

| Compressive zog |

—– |

Mpa |

38.6 |

| Kub | |||

| Vicat Softening Kub |

≥140 |

°C |

154 |

| Hear Shrinkage140°C/150min(Length/Breadth) |

-3~+3 |

% |

-0.41/+0.41 |

| Tshuaj | |||

| 35% HCI |

±1.0 |

g/ cm2 |

-0.12 |

| 30% H2SO4 |

±1.0 |

g/ cm2 |

-0.08 |

| 40% HNO3 |

±1.0 |

g/ cm2 |

-0.02 |

| 40% NaOH |

±1.0 |

g/ cm2 |

-0.08 |

R&D

1.Our company adopts environment-friendly raw materials.Strictly control the production process, from raw materials to the factory layer quality inspection.The

experimental testing follows the international quality management and certification

system to ensure the quality of products.

2.Our company set up a number of independent experiments, with a high degree of

automation of the production equipment, every year to invest a lot of money, the

introduction of talent and technology, has a strong scientific research force.