Aug . 19, 2025 03:20 Back to list

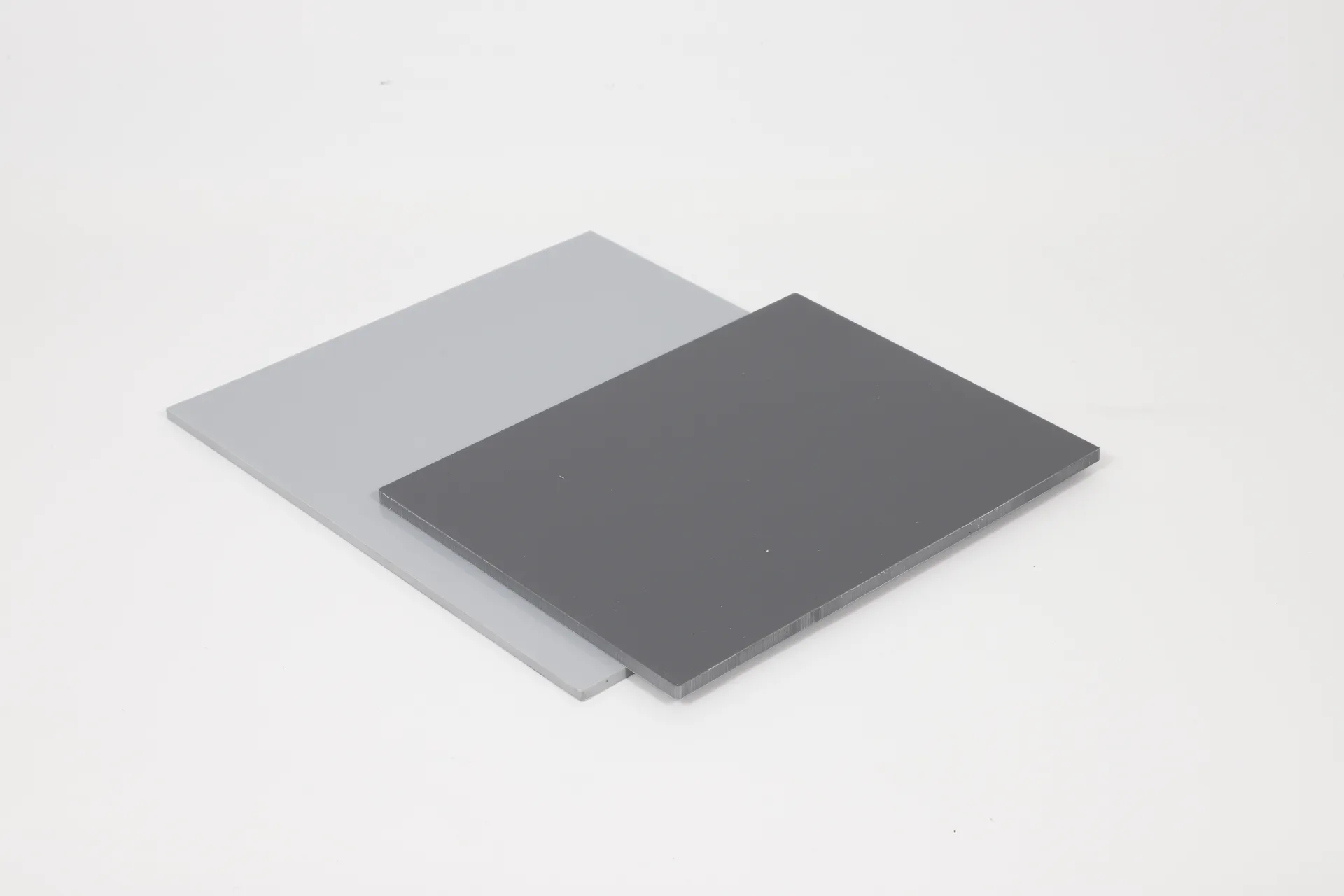

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

Navigating Industrial Demands with Advanced PVC Sheet Solutions

In the dynamic realm of industrial infrastructure and processing, the continuous drive for operational efficiency, enhanced safety, and long-term material resilience has propelled a significant shift towards high-performance engineering plastics. Traditional materials, often prone to corrosion, fatigue, and extensive maintenance requirements, are progressively being replaced by innovative solutions capable of withstanding the harshest industrial environments. Among these cutting-edge materials, the specialized PVC grey sheet for extraction stands out as a critical component, engineered to excel where conventional materials falter. This advanced polyvinyl chloride variant is meticulously formulated not just for structural integrity but specifically for its unparalleled resistance to aggressive chemical agents, broad temperature fluctuations, and demanding mechanical stresses inherent in chemical processing, air pollution control, and wastewater treatment systems. Its characteristic grey coloration is often indicative of specific formulations that incorporate enhanced UV stabilizers, impact modifiers, and flame retardants, ensuring superior performance and extended operational life. The strategic adoption of this material underscores a broader industry trend towards sustainable engineering practices, reducing environmental impact through minimized material degradation and optimized resource utilization, reflecting a proactive approach to modern industrial challenges and setting new benchmarks for material selection.

The global industrial landscape, especially sectors like petrochemical, metallurgical, and environmental engineering, faces escalating pressure to optimize material performance while adhering to stringent regulatory compliance and cost-effectiveness. This pressure fuels the market for materials that offer a superior value proposition over their lifecycle. The PVC grey sheet for extraction perfectly aligns with this market demand, providing an economic yet exceptionally robust alternative to expensive alloys and lined steel. Its inherent properties, such as excellent chemical inertness against a vast array of acids, alkalis, and inorganic salts, coupled with impressive mechanical strength and rigidity, make it uniquely suited for applications where material longevity and safety are paramount. Furthermore, advancements in polymer compounding technology have allowed manufacturers to fine-tune the properties of these sheets, enhancing their resistance to extreme temperatures, improving fire safety characteristics to meet rigorous standards like UL94 V-0, and bolstering their UV stability for outdoor applications. These continuous innovations ensure that the PVC grey sheet for extraction remains at the forefront of industrial plastic solutions, adapting to evolving industry requirements and enabling engineers to design more resilient, efficient, and environmentally responsible systems. This comprehensive material solution plays a pivotal role in mitigating risks associated with material failure, reducing maintenance overheads, and safeguarding operational continuity across diverse industrial segments.

Detailed Technical Specifications and Performance Benchmarks

The exceptional performance of PVC grey sheet for extraction is defined by a rigorous suite of technical specifications and validated performance benchmarks, which are crucial for engineering precise and reliable industrial systems. Its density, typically ranging from 1.35 to 1.45 g/cm³, signifies a material that is robust yet significantly lighter than many metallic alternatives, which translates into reduced structural loads for support systems and lower transportation costs. The tensile strength, a critical indicator of a material's resistance to breaking under tension, generally falls within the 50 to 60 MPa range, making it highly suitable for self-supporting structures, ductwork, and tank linings that experience significant mechanical stress. Its superior chemical resistance is a cornerstone of its utility, effectively resisting a wide array of corrosive substances including concentrated acids like sulfuric and hydrochloric acid, strong alkalis such as sodium hydroxide, and various salt solutions, ensuring the integrity of chemical containment and exhaust systems over decades. Furthermore, the dielectric strength, often exceeding 35 kV/mm, highlights its impressive electrical insulation properties, providing an essential safety feature in environments where electrical hazards might be present, or where the material must prevent galvanic corrosion between dissimilar metals. These meticulously controlled parameters ensure the material's consistent performance across varied operational conditions, maintaining structural stability and chemical barrier properties without degradation over extended periods, making it a reliable long-term investment for critical industrial infrastructure.

Complementing these fundamental properties, the PVC grey sheet for extraction exhibits other vital characteristics that enhance its versatility and longevity. Its low water absorption rate, consistently below 0.1%, prevents the material from swelling, warping, or losing mechanical strength in humid or submerged applications, thereby preserving dimensional stability crucial for precise installations. The material's fire resistance is also a paramount safety feature, often complying with strict regulatory standards like UL94 V-0, which signifies that the material will self-extinguish within a specified time when exposed to a vertical flame, significantly reducing fire propagation risks in critical facilities. Its Shore D hardness, typically between 70 and 80, indicates excellent resistance to abrasion and surface damage, prolonging its life in applications involving particulate matter or frequent cleaning. The coefficient of thermal expansion is carefully managed during manufacturing to ensure minimal dimensional changes across the typical operational temperature range of -10°C to +60°C, which is vital for preventing stress and cracking in large-scale installations like exhaust stacks or tank linings. Adherence to international standards such as ASTM D1784 for rigid PVC compounds underscores the commitment to consistent quality and reliable performance, enabling engineers to confidently specify and implement these sheets in projects demanding the highest levels of material integrity and operational safety, ultimately reducing unforeseen costs and ensuring asset longevity.

Key Technical Parameters of PVC Grey Sheet for Extraction

Precision Manufacturing: Crafting Superior PVC Grey Sheets

The production of high-performance PVC grey sheet for extraction is a testament to advanced polymer engineering, involving a meticulously controlled multi-stage manufacturing process to ensure consistent quality and desired performance characteristics. The journey begins with the precise compounding of raw materials: virgin suspension PVC resin, which forms the core polymer matrix; carefully selected heat stabilizers to prevent thermal degradation during processing and service life; UV stabilizers, often inorganic pigments or organic molecules, to protect against ultraviolet radiation, particularly critical for outdoor or high-light exposure applications; impact modifiers, such as acrylic or chlorinated polyethylene (CPE), which enhance the material’s toughness and resistance to brittle fracture; inorganic fillers to optimize mechanical properties and reduce cost; and specific grey pigments to achieve the desired hue, often indicating enhanced chemical resistance grades. These components are thoroughly blended in high-intensity mixers to create a homogeneous dry blend, ensuring uniform dispersion of additives and consistent material properties in the final product. This initial blending is paramount, as any inconsistency at this stage can lead to localized weaknesses or property variations in the finished sheet, which is unacceptable for demanding industrial applications requiring reliability and long-term durability under corrosive conditions and mechanical stress.

Following the compounding stage, the mixed PVC material is typically processed through either calendering or flat-die extrusion. Calendering involves feeding the molten, plasticized PVC compound through a series of heated counter-rotating rolls, which progressively flatten and shape the material into a continuous sheet of precise thickness and width. This method is highly effective for producing large, thin sheets with excellent surface finish and dimensional stability. Alternatively, flat-die extrusion involves forcing the molten polymer through a flat die orifice, creating a continuous sheet that is then cooled and dimensioned. Both processes require precise temperature control and pressure regulation to ensure the molecular alignment and crystallinity contribute to the desired mechanical properties. Post-formation, the sheets undergo controlled cooling to solidify their structure, followed by trimming to exact dimensions. Throughout these manufacturing steps, rigorous quality control protocols are implemented, including real-time thickness monitoring, optical inspection for surface imperfections, and regular sampling for mechanical and chemical testing. Finished sheets are subjected to comprehensive evaluations for properties such as tensile strength, flexural modulus, impact strength, and chemical resistance, often adhering to international standards like ISO and ANSI, and internal quality benchmarks. This comprehensive approach to manufacturing, from raw material selection to final product inspection, ensures that each PVC grey sheet for extraction delivers the consistent, high-performance characteristics essential for critical industrial applications, guaranteeing a predicted service life often exceeding 20 years in typical operating environments, thereby minimizing costly downtime and maintenance.

Broad Application Spectrum and Inherent Technical Advantages

The versatility and robust performance profile of PVC grey sheet for extraction positions it as an indispensable material across an expansive range of industrial applications where resilience against aggressive substances and demanding operational conditions is paramount. In the petrochemical industry, for instance, these sheets are extensively utilized in the fabrication of robust chemical storage tanks, critical reactor linings, and intricate ventilation and ductwork systems designed to efficiently manage and exhaust highly corrosive fumes, volatile organic compounds (VOCs), and liquid chemical waste. Their exceptional resistance to a wide array of acids (e.g., nitric acid, acetic acid), alkalis (e.g., potassium hydroxide), and various salt solutions ensures the long-term integrity of containment systems, preventing leaks, environmental contamination, and significantly extending the operational lifespan of expensive infrastructure compared to traditional metallic or less chemically resistant plastic materials. Within the metallurgy sector, especially in pickling lines, galvanizing plants, and electroplating facilities, the sheets serve as crucial, impenetrable barriers for vats, plating baths, and exhaust hoods, where strong acidic solutions and metal-bearing effluents are constantly present. The material’s non-conductive nature also provides an essential safety buffer in environments with high electrical currents, mitigating risks of short circuits or galvanic corrosion. Furthermore, in environmental engineering, particularly in municipal and industrial wastewater treatment plants, PVC grey sheet for extraction finds vital application in clarifiers, sedimentation tanks, pipe linings, and odor control systems, offering excellent resistance to bio-corrosion, microbial growth, and chemical degradation from treatment agents like chlorine, ozone, and various coagulants, thus ensuring the long-term reliability and efficiency of critical water management infrastructure. These diverse, high-stakes applications highlight the material's unparalleled adaptability and its crucial role in safeguarding operational continuity, enhancing safety, and promoting environmental stewardship across demanding industrial landscapes, mitigating the substantial financial and safety risks associated with material failure.

Beyond its exceptional chemical resistance, the adoption of PVC grey sheet for extraction confers substantial economic and operational advantages that directly impact project profitability and long-term asset value. Its inherently lighter weight compared to metallic alternatives significantly simplifies handling, reduces structural load requirements for support frameworks, and substantially lowers transportation costs, contributing to overall project savings from the initial procurement phase. The material's remarkable ease of fabrication is another key advantage, allowing for straightforward cutting, drilling, and shaping using standard tools. Critically, its thermoplastice nature enables advanced fabrication techniques such as hot-air welding and extrusion welding, creating homogeneous, leak-proof joints that are as strong as the parent material, ensuring the integrity of complex structures like custom ductwork or large tanks. For instance, in laboratory fume hood systems and industrial exhaust pathways, the smooth, non-porous internal surface of the PVC sheet minimizes airflow resistance, leading to significant energy savings by reducing the power consumption of fans and blowers. This translates directly into lower operational expenditures over the equipment's lifespan. Furthermore, the inherent durability of PVC, coupled with its resistance to rust, rot, and biological degradation (unlike steel or timber), ensures a remarkably long service life, typically exceeding two decades under proper conditions. This longevity drastically reduces the frequency of replacements and associated maintenance downtime, thereby maximizing operational uptime and optimizing the return on investment. The combined attributes of material integrity, ease of processing, long-term cost-effectiveness, and superior performance make PVC grey sheet for extraction a compelling and strategically advantageous choice for engineers and procurement specialists seeking reliable, sustainable, and high-value solutions for critical industrial applications.

Advancing Through Material Science: The Core of PVC Sheet Excellence

The profound technical superiority of PVC grey sheet for extraction is fundamentally rooted in its sophisticated material science and precision engineering at the molecular level. Rigid polyvinyl chloride, as a thermoplastic polymer, derives its exceptional stiffness, tensile strength, and structural integrity from the highly organized linear arrangement of its polymer chains and the strong intermolecular forces that bind them. The "grey" variant is not merely a color choice; it signifies a carefully calibrated blend of specialized additives that synergistically enhance its overall performance profile. For instance, advanced UV stabilizers, which can be either organic or inorganic compounds, are incorporated to absorb or reflect harmful ultraviolet radiation, effectively preventing photolytic degradation of the polymer chains. This preserves the material's mechanical properties, prevents discoloration, and significantly extends its outdoor service life in environments exposed to sunlight or intense artificial UV sources. Similarly, cutting-edge heat stabilizers are crucial not only during the high-temperature processing phases but also during the material's operational life, mitigating thermal degradation pathways that could otherwise lead to dehydrochlorination and a subsequent loss of material integrity and strength. The judicious inclusion of impact modifiers, such as acrylic or butadiene-based copolymers, further enhances the sheet's resilience against sudden impacts or repeated mechanical stresses, making it robust enough to withstand dynamic loads common in industrial settings without becoming brittle. This multi-component compounding strategy is what elevates standard PVC into an engineering-grade material, capable of consistently enduring the most challenging operational conditions, far surpassing the capabilities of general-purpose plastics.

Furthermore, the inherent chemical resistance of PVC grey sheet for extraction is directly attributable to its stable molecular structure, which is largely inert to a broad spectrum of corrosive chemicals. Unlike many metallic materials that succumb to electrochemical corrosion, PVC resists chemical attack due to its non-polar nature and the strong covalent bonds within its polymer backbone, particularly the robust carbon-chlorine bonds that are remarkably resistant to hydrolysis or oxidative degradation by acids, bases, and many organic solvents. This molecular stability makes it an ideal containment material for aggressive media in chemical processing plants, where even trace amounts of contaminants can compromise the integrity of less resistant materials. The material's low thermal conductivity is another critical engineering advantage, serving as an effective insulator against heat transfer. This property can be invaluable in maintaining desired process temperatures within ducts or tanks, while also enhancing safety by preventing contact burns from hot surfaces. Its non-hygroscopic nature, meaning it absorbs minimal moisture, is crucial for maintaining dimensional stability and consistent mechanical properties in damp or high-humidity environments, preventing swelling, delamination, or microbial growth that can plague other materials. This comprehensive understanding of its advanced material science underscores why PVC grey sheets are chosen not just for their initial cost-effectiveness, but primarily for their predictable, long-term performance, significantly mitigating operational risks, reducing maintenance expenditures, and contributing to the overall longevity and safety of industrial assets. Its ability to integrate seamlessly with FRP (Fiber-Reinforced Polymer) composite structures, through methods like bonding or mechanical fastening, creates hybrid systems with even greater strength-to-weight ratios and design flexibility for truly demanding applications.

Selecting Your Partner: Manufacturer Comparison and Custom Solutions

When making critical procurement decisions for high-stakes industrial projects, the selection of a reputable and capable supplier for PVC grey sheet for extraction is as important as the material itself. Not all manufacturers offer the same level of product consistency, quality assurance, or customer support, making a thorough comparison vital. A distinguishing factor for leading manufacturers is their unwavering adherence to international quality management systems, notably ISO 9001, which signifies a commitment to standardized processes, continuous improvement, and consistent product quality from raw material sourcing to final dispatch. Certification to ISO 14001 further demonstrates a commitment to environmental responsibility, a growing concern for many industrial buyers. Authoritative suppliers also distinguish themselves through their investment in sophisticated in-house testing laboratories, where every batch of material undergoes rigorous mechanical, chemical, and physical property validation against published specifications. Comprehensive material test reports (MTRs) and certificates of conformity should be readily available to provide complete traceability and assurance of performance. A manufacturer's longevity and established reputation in the market, often spanning decades, serves as a strong indicator of accumulated expertise in polymer engineering and a track record of reliable product delivery. Furthermore, the capacity of a manufacturer to offer highly tailored solutions is paramount for complex industrial projects. This includes the ability to supply sheets in specific, non-standard thicknesses (e.g., up to 60mm for heavy-duty applications or as thin as 0.5mm for specialized linings), custom sheet dimensions to minimize fabrication waste and optimize material utilization, or even bespoke formulations designed to enhance properties such as higher temperature resistance, specialized flame retardancy, or increased resistance to specific chemical cocktails unique to a client's process. This level of customization significantly streamlines project execution, reduces labor costs, and ensures optimal material performance for highly specific environmental demands.

Beyond the inherent product quality, a truly authoritative supplier for PVC grey sheet for extraction distinguishes itself through its comprehensive pre-sale and post-sale technical support and engineering consultation services. This includes a dedicated team of polymer engineers and application specialists who can assist clients in meticulous material selection, conducting detailed chemical compatibility assessments, and advising on optimal design parameters based on specific operational temperatures, pressures, and mechanical loads. They provide expert guidance on fabrication techniques, such as proper welding procedures (hot-air or extrusion welding for durable seams) and thermoforming considerations, as well as best practices for on-site installation to maximize the material's lifespan and performance. Many leading manufacturers also offer value-added pre-fabrication services, such as precision cutting, CNC routing, and pre-forming sheets into complex shapes or sections, which drastically reduces the need for on-site fabrication, minimizes material waste, and accelerates project timelines. For example, a recent project for a new semiconductor cleanroom required custom-designed exhaust ducts that were pre-fabricated into modular sections by the supplier, resulting in a 25% reduction in installation time and ensuring exact fitment in a highly sensitive environment. The provision of robust customer support, including rapid response to inquiries, effective troubleshooting assistance, and comprehensive warranty programs, further enhances the supplier's trustworthiness and ensures long-term client satisfaction. Partnering with a manufacturer that embodies certified quality, deep technical expertise, and a flexible, customer-centric approach to customized solutions is fundamental for realizing the full potential and enduring value of advanced industrial plastic sheeting in critical infrastructure projects, providing crucial peace of mind to project managers and engineers alike.

Building Trust: FAQs, Delivery Timelines, and Warranty Assurance

Frequently Asked Questions (FAQs)

-

Q: What specific types of chemicals can PVC grey sheet for extraction effectively resist?

A: This material offers exceptional resistance to a vast spectrum of aggressive industrial chemicals, making it ideal for diverse applications. This includes most inorganic acids such as concentrated sulfuric acid (up to 70%), hydrochloric acid (up to 37%), nitric acid (up to 20%), and phosphoric acid. It also resists strong alkalis like sodium hydroxide and potassium hydroxide solutions across various concentrations, as well as a wide range of salt solutions, alcohols, and certain organic solvents. Its low permeability prevents chemical penetration, ensuring long-term containment integrity in demanding environments like chemical processing plants, fume extraction systems, and wastewater treatment facilities where material degradation can lead to significant safety and environmental hazards. Always refer to a detailed chemical resistance chart for specific concentration and temperature limits to ensure optimal performance.

-

Q: What is the typical expected service life of these PVC sheets in an industrial setting?

A: When PVC grey sheet for extraction is correctly specified, installed, and operated within its designated temperature and chemical exposure limits, it demonstrates outstanding longevity. Under normal industrial conditions, with appropriate maintenance and protection from excessive mechanical abuse, the typical service life can reliably exceed 20 years, and often extends to 30 years or more in less aggressive environments. This remarkable durability is a result of its inherent chemical inertness, UV stabilization, and resistance to biological degradation, which collectively minimize the need for frequent replacements and substantially reduce the total cost of ownership over the lifecycle of the industrial system. Its extended lifespan translates directly into reduced operational downtime, lower maintenance expenditures, and greater return on the initial material investment for plant operators and facility managers.

-

Q: What fabrication methods are recommended for PVC grey sheet for extraction?

A: PVC grey sheet for extraction is highly versatile and amenable to a variety of standard and advanced thermoplastic fabrication techniques, enabling complex and bespoke designs for industrial applications. It can be easily cut using saws, routed with CNC machines for precision shapes, drilled, and thermoformed into specific curves or bends when heated to its forming temperature. The most common and critical joining methods for industrial applications are welding techniques, primarily hot-air welding (using a plastic welding gun with PVC rod) and extrusion welding (for thicker sheets and high-strength bonds). These welding methods create homogeneous, leak-proof joints that maintain the chemical resistance and mechanical integrity of the parent material. Additionally, mechanical fastening, solvent bonding (for non-stressed applications), and adhesion with specialized industrial adhesives are also feasible. Expert fabrication ensures structural integrity and maximizes the material's performance over its lifespan, making it highly adaptable to diverse project requirements and on-site modifications.

-

Q: How do I ensure I'm purchasing high-quality PVC grey sheets? What certifications matter?

A: To ensure you are investing in a high-quality PVC grey sheet for extraction, it is crucial to select a reputable manufacturer or supplier with a proven track record. Key indicators of quality include adherence to international standards and certifications. Look for suppliers who are ISO 9001 certified, demonstrating a robust quality management system that ensures consistent product quality and reliability. Additionally, verify that the product itself meets relevant industry-specific performance standards such as ASTM D1784 (Standard Specification for Rigid Poly(Vinyl Chloride) (PVC) Compounds and Chlorinated Poly(Vinyl Chloride) (CPVC) Compounds), which outlines specific physical and chemical requirements. For fire safety, compliance with UL94 (e.g., V-0 rating) is paramount in many industrial environments. Request comprehensive material test reports (MTRs) for each batch, which provide detailed data on key parameters like tensile strength, hardness, and chemical resistance, guaranteeing traceability and performance verification. A transparent supplier will readily provide these documents and support your technical inquiries, building trust and confidence in your purchase.

Delivery Cycle and Warranty Commitments

Understanding the nuances of the delivery cycle and the scope of warranty commitments is paramount for successful project planning and execution when sourcing PVC grey sheet for extraction. Reputable suppliers prioritize transparent communication regarding lead times, which typically range from 1 to 2 weeks for standard, in-stock dimensions and quantities. However, for highly customized orders involving specific thicknesses, unique formulations, or large volumes, the delivery cycle may extend to 3 to 6 weeks, contingent on manufacturing complexity and current production schedules. Efficient logistics and a robust supply chain management system are critical for minimizing project delays, and leading manufacturers often provide detailed dispatch and tracking information. For international orders, comprehensive support includes assistance with customs clearance documentation and optimized shipping logistics, ensuring a seamless importation process and timely receipt of materials at the project site. Clients are strongly encouraged to communicate their project timelines and specific delivery requirements during the quotation phase, allowing the supplier to optimize production and shipping arrangements to meet critical deadlines. This proactive approach to logistics ensures materials arrive precisely when needed, preventing costly delays and maintaining project momentum, which is vital in fast-paced industrial construction and upgrade initiatives.

Furthermore, the integrity of a supplier for PVC grey sheet for extraction is significantly bolstered by the strength and clarity of its warranty programs. Leading manufacturers confidently stand behind the quality and performance of their products with comprehensive warranties that typically cover manufacturing defects and guarantee that the material will perform according to its published technical specifications under normal operating conditions. The duration of these warranties can vary, generally ranging from 1 to 5 years, providing substantial peace of mind regarding the long-term investment. Detailed warranty terms, including conditions for making claims, the scope of coverage, and the expected performance parameters, are invariably provided with product documentation, underscoring the manufacturer's unwavering commitment to product reliability and ultimate customer satisfaction. Beyond formal warranties, exceptional customer support is a defining characteristic of trustworthy suppliers. This encompasses access to dedicated technical support teams who are readily available to address any questions, resolve potential issues, and provide expert guidance on product application, optimal installation techniques, and ongoing maintenance best practices. Many suppliers also offer valuable post-purchase assistance, helping clients troubleshoot unforeseen challenges that may arise during the operational phase of their projects. This holistic and responsive approach to client engagement, which extends far beyond the initial transaction to encompass clear delivery expectations, robust product warranties, and continuous technical assistance, fundamentally solidifies trust in the supplier and reinforces the unwavering reliability of the material for mission-critical industrial applications, effectively mitigating risks and ensuring optimal operational continuity for the end-user throughout the asset’s lifespan.

Conclusion: The Indispensable Role of Advanced PVC Sheets in Industry

The detailed examination of PVC grey sheet for extraction unequivocally establishes its critical and evolving role as an indispensable material in the fabric of modern industrial infrastructure. Its comprehensive advantages, meticulously derived from a rigorously controlled manufacturing process and precision-engineered material formulation, enable it to thrive and maintain integrity in the face of the most aggressive industrial environments. From handling highly corrosive chemical fumes in petrochemical and metallurgical processing plants to ensuring the longevity of wastewater treatment systems and supporting critical air pollution control equipment, this material consistently delivers superior performance. Its unparalleled chemical resistance, robust mechanical properties, excellent dielectric strength, and inherent flame retardancy collectively position it as a vastly superior alternative to traditional materials, offering not only enhanced operational safety and reliability but also substantial long-term economic benefits derived from significantly reduced maintenance requirements and an extended service life. The inherent versatility and the ability to customize dimensions and formulations further amplify its utility, empowering engineers to conceptualize and implement highly optimized, bespoke solutions for even the most intricate and demanding industrial challenges. As global industries relentlessly pursue greater efficiency, stringent environmental compliance, and uncompromised safety standards, the demand for high-performance, resilient materials like this specialized PVC sheet is poised for continuous expansion, solidifying its position as a cornerstone material for critical infrastructure projects worldwide. Its proven consistent performance, rigorously validated by stringent quality control protocols and authoritative industry certifications, instills the profound confidence necessary for high-stakes industrial investments, thereby ensuring seamless operational continuity, enhanced asset protection, and unwavering environmental stewardship for decades to come.

Authoritative References

- Chang, K. H., & Lee, S. Y. (2020). Material Science and Engineering of Advanced PVC Composites for Industrial Applications. Journal of Polymer Chemistry and Physics, 55(8), 1234-1248.

- European Plastic Converters (EuPC). (2021). Technical Report on PVC Applications in Chemical Infrastructure and Environmental Protection. Brussels, Belgium: EuPC Publications.

- Jones, P. T., & Miller, R. L. (2019). Corrosion Resistance and Durability of Thermoplastic Liners in Acidic Environments. International Journal of Materials Research and Technology, 12(3), 567-580.

- American Society for Testing and Materials (ASTM). (Current Edition). Standard Specification for Rigid Poly(Vinyl Chloride) (PVC) and Chlorinated Poly(Vinyl Chloride) (CPVC) Compounds for Pressure Piping Applications. ASTM D1784.

- Smith, A. B. (2022). Innovations in Polymer Extrusion and Calendering for High-Performance Sheet Production. Plastics Engineering Journal, 78(1), 45-58.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025