|

No. |

Items |

Requirement |

Result |

||

|

1 |

Density,g/cm3 |

ρ≤1.45 |

1.447 |

||

|

2

|

Mechanical Property

|

Tensile Strength/MPa |

≥40 |

42.2 |

|

|

Notch impact strength/ kJ/m2 |

≥5 |

5.5 |

|||

|

3

|

Thermal performance

|

Vicat softening point/℃ |

≥75 |

78.0 |

|

|

Heating dimension change rate/% |

Transverse |

±4 |

﹢0.5 |

||

|

|

Direction |

±4 |

-3.0 |

||

|

4

|

Corrosivity,g/m2 5h 60℃

|

35%±1 (V/V) HCL |

± 1 |

0.55 |

|

|

30%±1 (V/V) H2SO4 |

± 1 |

0.5 |

|||

|

40%±1 (V/V) HNO3 |

± 1 |

-0.8 |

|||

|

40%±1 (V/V) NaOH |

± 1 |

0.05 |

|||

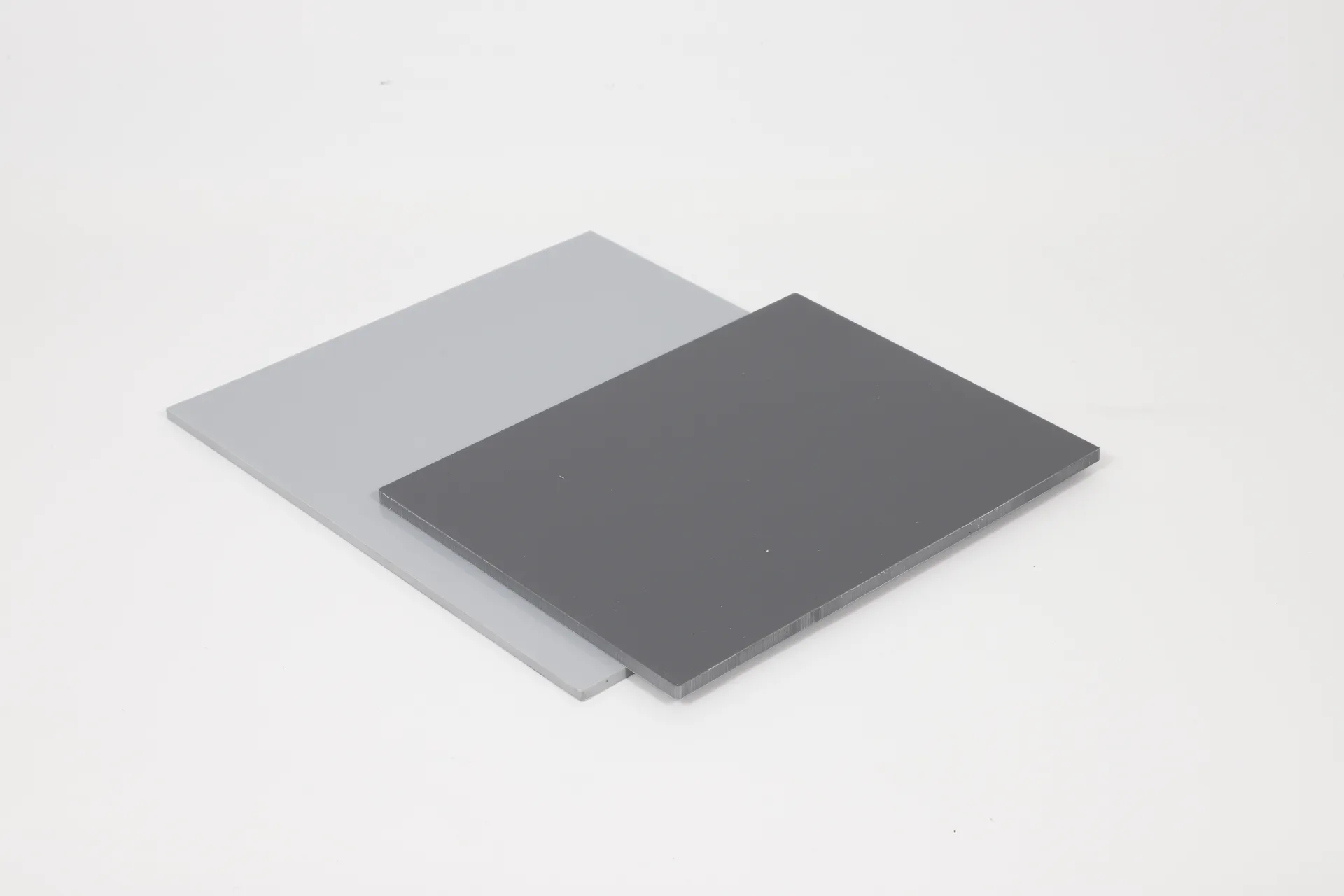

Characteristics

Excellent chemical and corrosion resistance;

Excellent impact strength;

Easily to fabricate, weld or machine;

High rigidity and superior strength;

Reliable electrical insulation;

Good features for printing;

Low flammability,

Self-extinguishing.

Applications

PVC rigid sheets are widely used in general and chemical industries, such as Lab equipment, Etching equipment, Semiconductor processing equipment, plating barrels, water tank, chemical storing tank, oil tank, storing tank for brewing water, acid or alkali production tower, acid or alkali washing tower, photograph developing instruments; Electrical industries for battery box, electrometer plate, electrolytic tank and various plates for electrical insulation, signboards for advertisement, wall cladding of office and public utilities, door panels and so on.

We can also produce milled parts from our PVC rigid sheet glossy surface.

If you need individual milled parts made of our PVC rigid sheet, this is no problem, we have the CNC milling centres with CNC control. Simply send us your enquiry with a sketch or a construction drawing stating the required quantity and we will prepare a tailor-made offer for your milled parts made of our PVC sheet.