Jul . 29, 2025 21:00 Back to list

High-Gloss PVC Rigid Sheet for Durable & Smooth Surfaces | Wholesale Supply

In the ever-evolving landscape of industrial plastics, PVC Rigid Sheet(glossy surface) stands out for its advanced engineering, durability, and versatile applications across a spectrum of industries. As industries push for cost optimization, longevity, and high-performance materials, the demand for high-gloss rigid PVC sheets has surged, with global market size for rigid PVC sheets projected to reach $4.6 billion by 2026 (Markets&Markets).

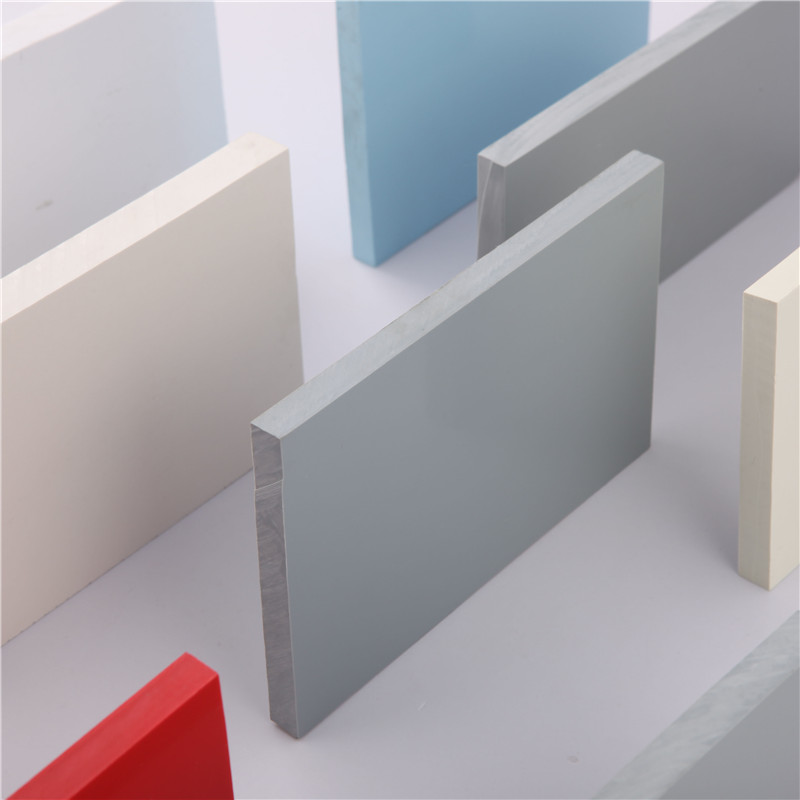

PVC Rigid Sheet(glossy surface): Premium High-Gloss Finish for Industrial Applications

Industry Trends & Market Dynamics

- Accelerated adoption driven by corrosion resistance and energy efficiency mandates in chemical, construction, and water treatment sectors.

- Asia-Pacific (APAC) region leads demand, accounting for over 45% of global market share.

- Regulatory push: ISO 9001:2015 and RoHS compliance now a standard procurement requirement.

- Technological upgrades: Shift towards co-extrusion techniques for enhanced surface gloss and uniformity.

- Custom colors and thicknesses now widely available to satisfy diverse engineering needs.

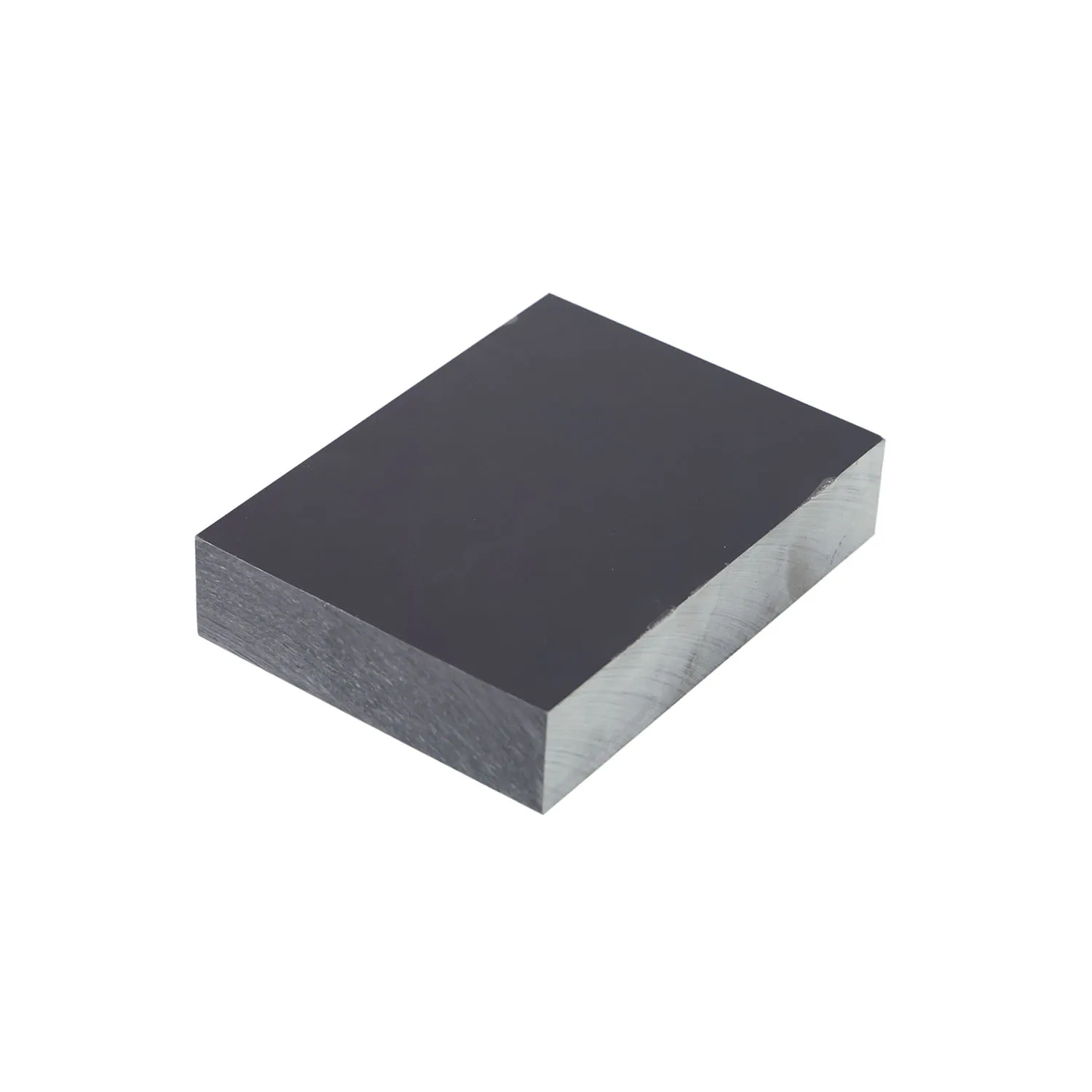

Technical Overview of PVC Rigid Sheet(glossy surface)

Primary Features

- Material: Virgin polyvinyl chloride, free of lead or phthalates.

- Surface: Ultra-smooth, high-gloss finish for enhanced aesthetics and easy cleaning.

- Thickness Range: 0.5–30 mm.

- Width: Up to 1300 mm (standard), with custom widths available.

- Physical Properties: High impact strength, chemical resistance, and UV stability. See comparison table below.

Versatile deployment of PVC Rigid Sheet(glossy surface) in modern construction & public infrastructure

Technical Parameters Table

| Parameter | Specification | Test Standard |

|---|---|---|

| Density | 1.38–1.42 g/cm³ | ASTM D792 |

| Tensile Strength | ≥52 MPa | ISO 527-1 |

| Elongation at Break | ≥20% | ISO 527-2 |

| Flexural Modulus | 2700–3200 MPa | ASTM D790 |

| Izod Impact Strength | ≥6 kJ/m² | ASTM D256 |

| Surface Hardness | ≥ Shore D 80 | ISO 868 |

| Thermal Deformation Temp. | 72–85℃ | ASTM D648 |

| Water Absorption (24h) | <0.04% | ISO 62 |

| Fire Resistance | V-0 (UL94) | UL94 |

Chemical & anti-corrosive applications of PVC Rigid Sheet(glossy surface) in storage tanks

Manufacturing Process Flow of PVC Rigid Sheet(glossy surface)

Raw PVC Resin Selection

Strict selection of Virgin PVC, additives mixed for flexibility and gloss.

→

High-Precision Extrusion

Resin melted, extruded through die at controlled temperatures (180–200°C).

→

Surface Treatments

Gloss optimized via calendering roll; anti-UV and anti-static agents applied.

→

Thickness Calibration

On-line thickness controls ensure uniformity (±0.03 mm tolerance).

→

Cutting & Inspection

CNC trimming, ISO/ANSI quality checks, and laser surface scanning.

→

Packing & Shipment

Anti-scratch film applied, packed for moisture-proof export delivery.

PVC Rigid Sheet(glossy surface) precision extrusion and calendering zone (production line perspective)

Video: High-Gloss PVC Rigid Sheet Manufacturing Line

Illustrative overview of PVC Rigid Sheet(glossy surface) manufacturing stages

Key Advantages of PVC Rigid Sheet(glossy surface)

- Superior Surface Gloss: High light reflectivity & anti-scratch compared to conventional rigid sheets.

- Extended Lifetime: Service life surpasses 20 years in typical indoor installations (certified by ISO 4892-2 accelerated aging tests).

- Chemical & UV Resistance: Maintains stability against acids, alkalis, salts & UV exposure.

- Excellent Dimensional Stability: ±0.05% expansion over 10 years usage (ASTM D1204).

- Customizable Profile: Wide spectrum of colors, finishes, and embossing on demand.

- Eco-friendly Formulation: 100% lead-free & RoHS compliant; fully recyclable.

Technical Parameters Trend Chart

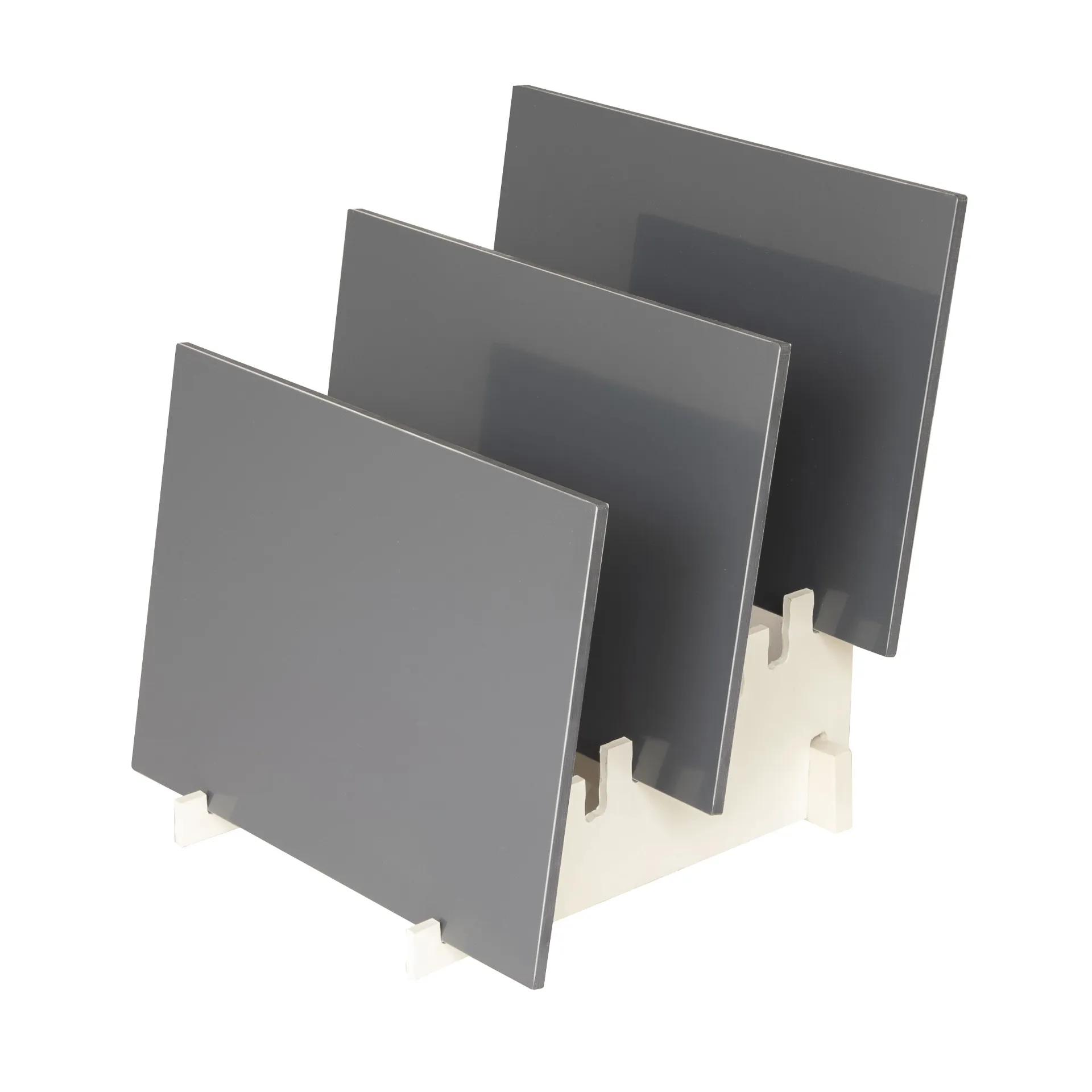

Specification & Performance Comparison

| Product | Tensile Strength | Flexural Modulus | Surface Gloss | UV Stability | Fire Rating |

|---|---|---|---|---|---|

| PVC Rigid Sheet(glossy surface) | ≥52 MPa | 3200 MPa | 93 GU* | Excellent | V-0 |

| Standard PVC Rigid Sheet | ≤45 MPa | 2700 MPa | 70–75 GU* | Good | V-1 |

| ABS Sheet (General) | 38–42 MPa | 2100 MPa | ~75 GU* | Average | HB |

*Gloss Unit (GU), measured at 60°.

Key Application Scenarios & Case Studies

Case Study: PVC Rigid Sheet(glossy surface) in Urban Chemical Plant Expansion (2023)

- Client: Guangdong GreenTech Chemicals Co.

- Need: Upgrade of storage tank lining & anti-corrosive wall panels, seeking V-0 fire rating and 20+ year service life.

- Solution: 8mm custom-colored PVC Rigid Sheet(glossy surface), CNC-cut, hot-welded on-site.

- Outcome: Reduced annual maintenance by 42%, improved process safety; certified to ISO 9001:2015; post-1yr inspection: zero blistering or color fade.

Real-world implementation: PVC Rigid Sheet(glossy surface) installation in chemical facility (2022)

Top Manufacturers Competitive Overview

| Manufacturer | Country | ISO Certification | Annual Output (tons) | OEM/Customization |

|---|---|---|---|---|

| Lida Plastic (View) | China | ISO 9001:2015 | 37,500 | Yes |

| Simona AG | Germany | ISO 9001 | 40,000 | Yes |

| Palram | Israel | ISO 14001 | 20,000 | Yes |

| Jindal Poly Films | India | ISO 9001 | 15,000 | Yes |

Customization & OEM Services

- Custom thickness range: 0.5–30 mm, tolerance ±0.03 mm

- Color matching: RAL/Pantone; custom surface embossing or matte options available

- Sheet size: up to 1300×4000 mm (larger sizes on request)

- CNC pre-cutting, Laser engraving, Sheet lamination

- Surface finishing: anti-scratch, anti-static, antimicrobial

- Private labeling & custom export packaging

For detailed technical advice and bespoke solutions, reach out via the Lida Plastic official contact page. Our R&D team supports material selection, performance testing, and cost optimization.

Frequently Asked Questions: Technical & Industry Terms

- 1. What does "gloss unit (GU)" mean for PVC Rigid Sheet(glossy surface)?

- Gloss Unit (GU) is a quantitative measure of surface reflectivity at a specified angle (commonly 60°). For PVC Rigid Sheet(glossy surface), values above 90 GU indicate high-luster, reflective surfaces, ideal for architectural and cleanroom settings.

- 2. Are sheets certified to international standards?

- Yes. Leading producers certify products to ISO 9001:2015, RoHS, and meet UL94 V-0 fire safety for industrial use. Alloyed solutions comply with FDA or EN standards where needed.

- 3. What are the common thickness and width tolerances?

- Modern lines achieve thickness tolerance of ±0.03 mm and width tolerance of ±2 mm, verified via laser measuring systems per ASTM D1594.

- 4. How is UV resistance tested?

- Accelerated aging chambers (ISO 4892-2) simulate multi-year sunlight exposure. Sheets showing <2% color shift after 2000h are considered "excellent UV stable".

- 5. Which industries most benefit from PVC Rigid Sheet(glossy surface)?

- Key sectors: chemical storage, lab equipment, wall cladding, signage, electronics, pharmaceutical infrastructure, and water treatment facilities.

- 6. Installation standard references?

- Installations typically follow DIN 16927 and ASTM D2563, focusing on joint-edge welding, expansion allowances, and chemical compatibility.

- 7. What is the expected delivery period and quality guarantee?

- Standard lead time: 10–18 working days. All sheets are backed by a 2-year warranty against delamination, excessive color fade, or cracking under normal use.

- 8. Can sheets be processed further after purchase?

- Yes, PVC Rigid Sheet(glossy surface) supports CNC routing, drilling, thermal bending, die-cutting, and digital printing with consistent edge quality.

Delivery, Warranty & Customer Support

- Regular delivery: 10–18 business days from order confirmation, with express options available.

- Warranty: 24 months against yellowing, cracking, or delamination under recommended service conditions.

- Technical support: Application engineering, on-site installation guidance, material selection assistance.

- After-sales services: Replacement or refund for proven defects; global shipping with ISO-certified traceability.

Customer References & Industry Certifications

- ISO 9001:2015, ISO 14001, RoHS, UL94 V-0 certifications across manufacturing.

- Trusted by Fortune 500 chemical, electronics & water-treatment firms in over 36 countries.

- Extensive history (since 1997) in OEM, custom projects & long-term partnerships.

- Referenced in materials science journals and global supply chain forums.

“The deployment of high-gloss rigid PVC sheets, particularly in advanced chemical storage, delivers unprecedented resistance to degradation and enhances operational safety well beyond traditional plastics.”

— S. Kumar, Materials Science Journal, Polymer Engineering & Science

— S. Kumar, Materials Science Journal, Polymer Engineering & Science

Share:

Latest news

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025