Oct . 10, 2025 10:40 Back to list

Need High-Clarity PVC Rigid Sheet (Glossy Surface)?

PVC Rigid Sheet(glossy surface) is a key solution in the manufacturing industry, specifically within plastic product industry and Manufacturing of plastic plates, sheets, pipes, and profiles. This article explores how Baoding Lida Plastic Industry Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- PVC Rigid Sheet(glossy surface) Overview

- Benefits & Use Cases of PVC Rigid Sheet(glossy surface) in Manufacturing of plastic plates, sheets, pipes, and profiles

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on PVC Rigid Sheet(glossy surface) from Baoding Lida Plastic Industry Co., Ltd

PVC Rigid Sheet(glossy surface) Overview

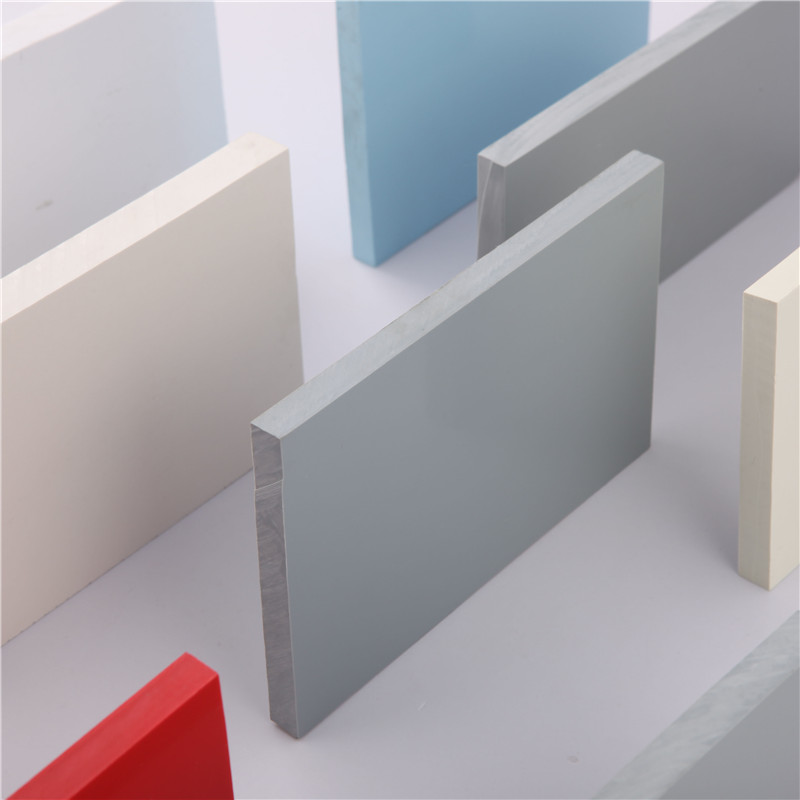

PVC Rigid Sheet(glossy surface) is an extruded or calendered polyvinyl chloride sheet engineered for high surface brilliance, dimensional stability, and consistent processing performance. For B2B buyers in the plastic product industry—especially those involved in Manufacturing of plastic plates, sheets, pipes, and profiles—the glossy finish provides an attractive, print‑ready surface while the rigid PVC substrate delivers reliable mechanical strength and chemical resistance. Typical characteristics include excellent surface gloss, tight thickness tolerances, good stiffness-to-weight ratio, and easy machinability for cutting, drilling, routing, and bending. The sheet is compatible with common fabrication methods such as thermoforming, vacuum forming, heat bending, solvent bonding, and hot‑air welding.

Baoding Lida Plastic Industry Co., Ltd manufactures PVC Rigid Sheet(glossy surface) in a range of thicknesses, colors, and surface treatments to match application needs—such as corona treatment for printing, protective film masking, and cut‑to‑size services. Consistent flatness and gloss enable downstream efficiency in printing, laminating, and assembly. In one representative application, fabrication shops replacing painted substrates with glossy PVC sheets reduced finishing steps, shortened production cycles, and achieved more uniform aesthetics, highlighting how the product can streamline operations from prototyping to high‑volume runs. With quality‑controlled production and experienced technical support, Baoding Lida is a dependable partner for OEMs and converters seeking repeatable results.

Benefits & Use Cases of PVC Rigid Sheet(glossy surface) in Manufacturing of plastic plates, sheets, pipes, and profiles

Across Manufacturing of plastic plates, sheets, pipes, and profiles, the PVC Rigid Sheet(glossy surface) serves as a versatile, value‑driven substrate. Fabricators use it for equipment panels, machine guards, and enclosure claddings where a clean, reflective appearance is desirable without secondary painting. In sheet and plate lines, it functions as a durable, chemical‑resistant panel for partitions, cleanroom wall systems, and process-area liners. For profile manufacturers, it can be cut into decorative fascias, trims, and protective covers that maintain consistent color and sheen. The material’s compatibility with solvent cements and welding promotes strong, sealed joints for ducting components, ventilation accessories, and cabinet assemblies.

Key advantages include: high surface gloss for premium branding or architectural finishes; stable dimensional control for precision routing and die‑cutting; resistance to moisture, many chemicals, and UV‑stabilized options for select outdoor uses; and good printability for graphics and labeling. Compared to alternatives like painted metal or certain ABS/HIPS grades, PVC Rigid Sheet(glossy surface) often reduces finishing steps, simplifies cleaning, and improves cost predictability. Baoding Lida Plastic Industry Co., Ltd leverages proven extrusion and surface-control know‑how to deliver uniform gloss and color consistency lot‑to‑lot, supporting repeatable workflows in B2B environments from industrial fabrication to signage and interior systems.

Cost, Maintenance & User Experience

Total cost of ownership for PVC Rigid Sheet(glossy surface) is attractive due to its favorable price‑performance ratio, low finishing requirements, and long service life in many environments. By eliminating painting in numerous applications and arriving with a protective film (when specified), the sheet can move from cutting to assembly with minimal rework. Its excellent machinability reduces tool wear and setup time, while tight thickness tolerances help lower scrap rates. For procurement teams comparing materials, PVC’s balance of stiffness, impact resistance, and aesthetics often outperforms more expensive substrates for enclosure panels, cladding, and printed components.

Maintenance is straightforward: the glossy surface resists staining and cleans easily with mild detergents; solvent and adhesive bonding options enable robust repairs if needed. Users in the plastic product industry report smoother downstream processes—consistent flatness aids CNC routing and thermoforming, and print‑ready gloss can reduce primer usage. In scenarios where parts require frequent wipe‑downs (e.g., food-adjacent processing areas or laboratories), PVC’s cleanability supports uptime and hygiene. When stored flat, away from heat and direct sunlight, the sheet maintains its appearance and performance, protecting ROI over extended production runs. Baoding Lida’s responsive service and stable lead times further enhance user experience and inventory planning.

Sustainability & Market Trends in manufacturing

Sustainability is reshaping material choices in manufacturing. PVC Rigid Sheet(glossy surface) supports circularity by allowing in‑process scrap collection and regrind usage under controlled conditions, reducing waste in sheet and profile operations. Many buyers are specifying lead‑free stabilizer systems and asking for documentation aligned with common market requirements (such as RoHS and REACH compliance upon request). Additionally, low‑VOC processing and clean surface finishes help downstream facilities minimize emissions associated with painting and coating, cutting both cost and environmental impact.

Market trends show strong adoption of high‑gloss PVC for digitally printed signage, interior fit‑outs, equipment enclosures, and cleanroom panels, driven by the material’s consistent appearance and fabrication ease. Regulatory attention to product stewardship and end‑of‑life options is encouraging material standardization and recyclability planning. Baoding Lida Plastic Industry Co., Ltd is actively aligned with these shifts—prioritizing stable formulations, quality control, and options that help customers meet evolving compliance and reporting needs. By investing in process efficiency and offering tailored specifications (color, gloss level, protective films, and print‑ready treatments), Baoding Lida enables manufacturers to hit performance targets while advancing their sustainability roadmaps and ESG commitments.

Conclusion on PVC Rigid Sheet(glossy surface) from Baoding Lida Plastic Industry Co., Ltd

For B2B decision makers in the plastic product industry, PVC Rigid Sheet(glossy surface) combines high‑end aesthetics with dependable mechanical properties, simplified fabrication, and strong total cost of ownership. It is a versatile choice for Manufacturing of plastic plates, sheets, pipes, and profiles—supporting everything from cladding and printed panels to thermoformed parts and system enclosures. Backed by the manufacturing experience of Baoding Lida Plastic Industry Co., Ltd, you gain consistency, service, and specification flexibility that streamline production.

Contact us: email: lidaplastic@ldsy.cn

Visit our website: https://www.lidaplastic.com

-

Comprehensive Guide To HDPE Pipes and Fittings | Durable & Sustainable Solutions

NewsNov.24,2025

-

HDPE Culvert Pipe – Durable, Flexible & Sustainable Infrastructure Solutions

NewsNov.24,2025

-

DWC HDPE Pipe – Durable, Cost-Effective Drainage and Conduit Solutions

NewsNov.23,2025

-

HDPE Drainage Pipe – Durable and Sustainable Water Management Solutions

NewsNov.23,2025

-

Durable and Sustainable HDPE Corrugated Pipe Solutions for Modern Infrastructure

NewsNov.23,2025

-

HDPE Water Pipe - Durable, Cost-Effective Water Solutions for Global Needs

NewsNov.22,2025