Oct . 27, 2025 14:50 Back to list

PVC Rigid Sheet(glossy surface) - Durable, Printable, Custom

What I’m Seeing in Glossy PVC Right Now

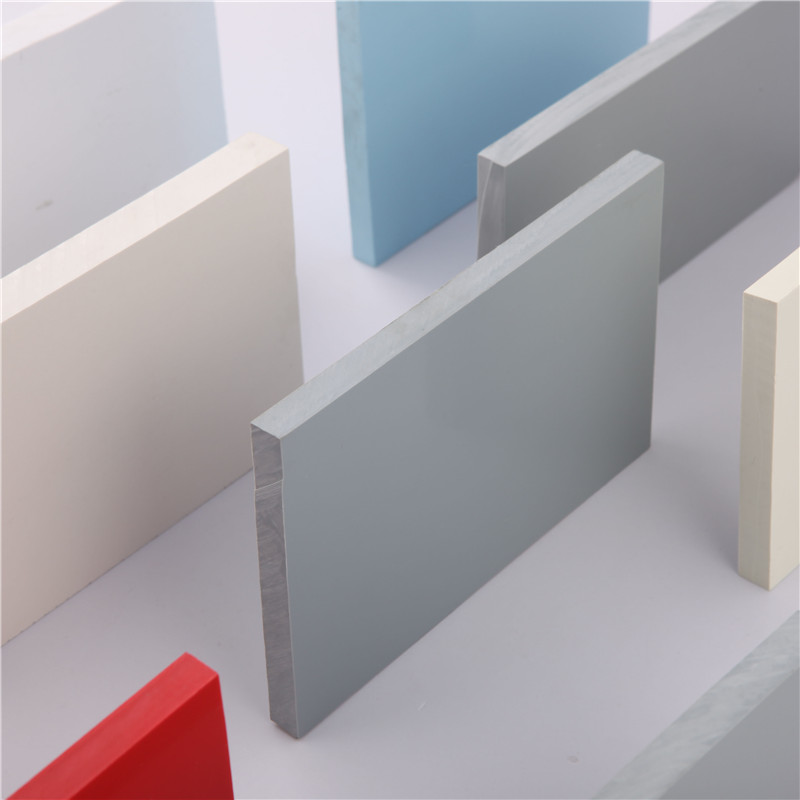

If you’ve been around fabrication workshops or signage plants lately, you’ve probably noticed the quiet comeback of glossy rigid PVC. The headline act for me is the PVC Rigid Sheet(glossy Surface) coming out of Baoding, Hebei. It’s practical, yes, but also better finished than most budget imports. And to be honest, the custom color matching is what wins buyers over.

Quick Specs at a Glance

| Thickness range | 1–60 mm |

| Width options | 1–3 mm: 1000–1300 mm; 4–20 mm: 1000–1500 mm; 25–30 mm: 1000–1300 mm; 35–60 mm: 1000 mm |

| Length | Any length (standard: 1220×2440, 1000×2000, 1500×3000 mm) |

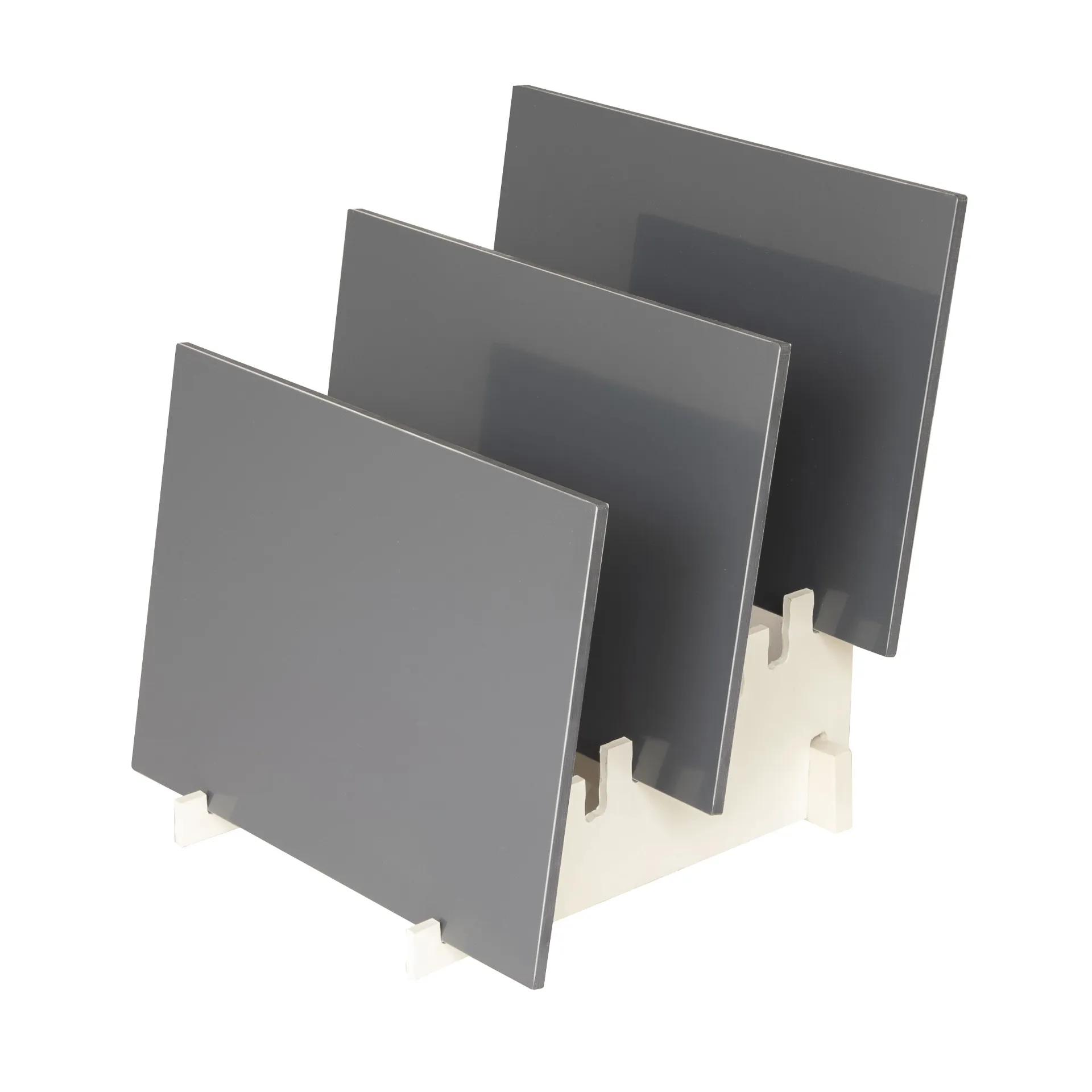

| Colors | Dark grey (RAL7011), light grey, black, white, blue, green, red; custom RAL/Pantone |

| Surface | High-gloss, protective film available |

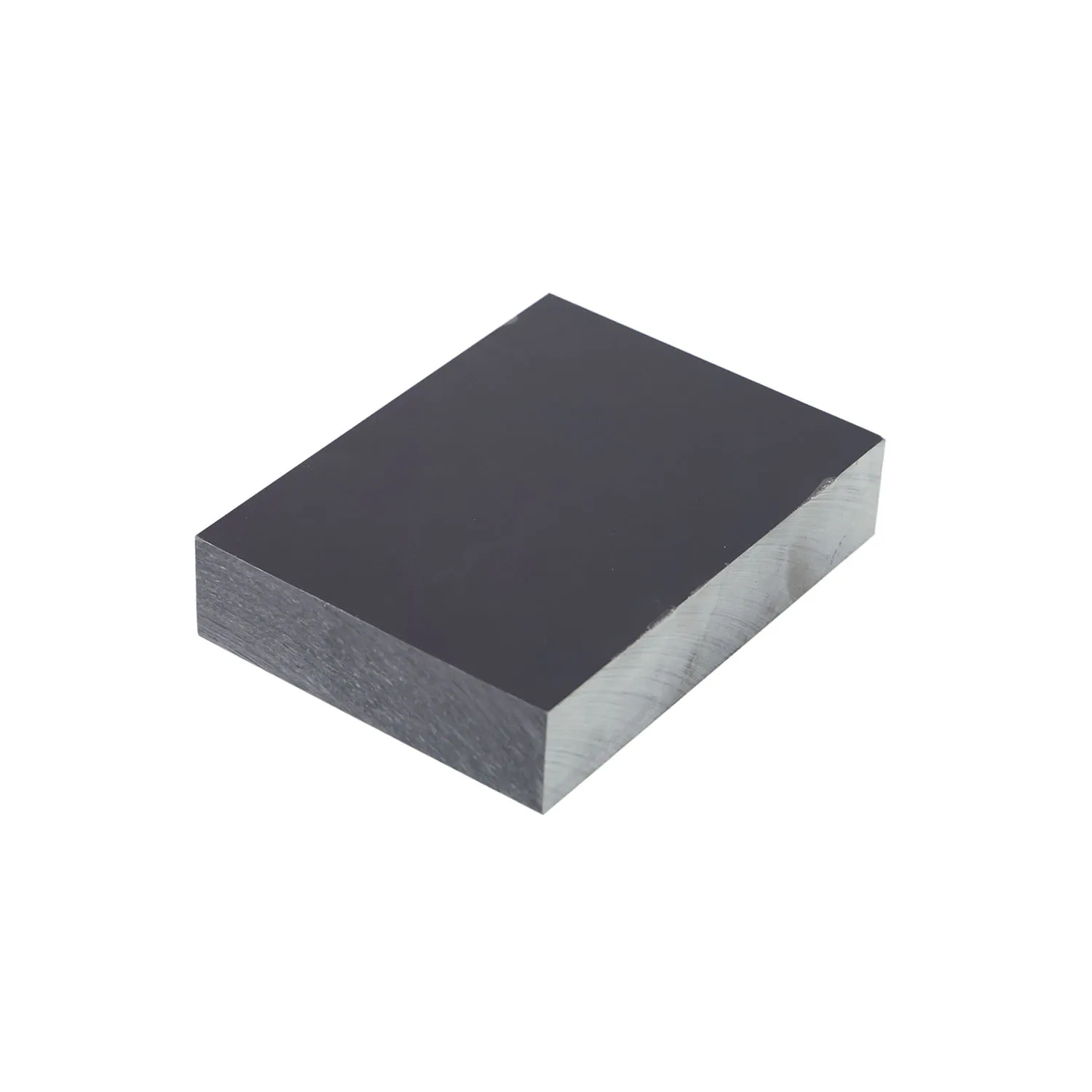

| Typical properties (≈) | Density 1.38–1.45 g/cm³; Tensile strength 45–55 MPa (ASTM D638); Shore D 78–82 (ISO 868); Vicat 73–80 °C (ISO 306); HDT 60–70 °C (ASTM D648); UL 94 V-0/V-2, formulation-dependent |

Where it’s Used (and Why)

- Retail and wayfinding signage—gloss pops under LED.

- Chemical-resistant linings, lab furniture, fume hood panels.

- Cleanroom cladding, pharma and food prep partitions.

- Electrical panel backplates and cable ducts (self-extinguishing grades).

- Vacuum forming of trays and machine guards.

Many customers say the gloss is easier to keep clean; it also looks “finished” without post-coating. Real-world service life: indoors 10–15 years; outdoors you’ll want UV-stabilized grades or a cap layer.

How It’s Made (short version)

Materials: PVC resin (K≈57–65), Ca-Zn or tin stabilizers, internal/external lubricants, impact modifiers, pigments.

Process flow: Dry blend → twin-screw extrusion or calendering → polishing stack for gloss → annealing → trimming → film lamination (optional) → QC.

QC and testing: cell classification per ASTM D1784; tensile (ASTM D638); impact (ASTM D256/ISO 179); Vicat (ISO 306); flammability UL 94; color ΔE and gloss units; thickness tolerance typically ±0.1–0.3 mm depending on gauge.

Vendor Snapshot and Comparison

| Vendor | Origin | Range | Lead time | Certs |

|---|---|---|---|---|

| Baoding Lida Plastic | No.316 Pingan West St., Shunping, Hebei, China | 1–60 mm, custom RAL | ≈10–18 days | RoHS, REACH, ISO 9001 (docs on request) |

| Trader A (generic) | Mixed | 1–20 mm | ≈3–5 days ex-stock | Varies |

| Regional Brand B | Local plant | Up to 30 mm | ≈2–3 weeks | ISO 9001 |

It seems that Lida’s edge is thicker gauges and more color certainty—useful for brand rollouts.

Customization, Packaging, and Docs

- Cut-to-size, film-masked gloss, edge chamfering, CNC-ready panels.

- RAL/Pantone matching; gloss target 70–90 GU at 60°, typical.

- Packaging: PE film + corner guards + pallet wrap; COA and batch traceability.

- Compliance: RoHS, REACH; UL 94 data by grade; material safety sheet on file.

Field Notes and Mini Case Studies

PVC Rigid Sheet(glossy Surface) for a pharma cleanroom walling job: dark grey RAL7011, 4 mm, adhesive fix on aluminum subframe; wipe-down tested with 70% IPA—no whitening after 100 cycles (in-house test). The contractor told me the gloss “hid” micro-scuffs better than matte.

Battery plant acid-resistant liner: 10 mm black sheets, hot air welded; service temp ~45 °C, acid mist present. After 9 months, welds intact; thickness loss negligible by caliper check—informal but encouraging.

Practical Tips

- Pre-drill and use oversized holes to allow movement; it’s PVC, not granite.

- Avoid prolonged >60–70 °C loads; check Vicat/HDT per grade.

- For outdoor use, ask for UV-stabilized or co-extruded cap—seriously.

Citations

- ASTM D1784 – Rigid PVC Compounds and Chlorinated PVC Compounds: https://www.astm.org/d1784

- ASTM D638 – Tensile Properties of Plastics: https://www.astm.org/d0638

- ISO 306 – Plastics—Vicat softening temperature: https://www.iso.org/standard/74722.html

- UL 94 – Tests for Flammability of Plastic Materials: https://ul.com/services/ul-94-flammability

- RoHS 2011/65/EU and REACH (EU) 1907/2006 Guidance: https://ec.europa.eu/environment/waste/rohs_eee/index_en.htm

-

Comprehensive Guide To HDPE Pipes and Fittings | Durable & Sustainable Solutions

NewsNov.24,2025

-

HDPE Culvert Pipe – Durable, Flexible & Sustainable Infrastructure Solutions

NewsNov.24,2025

-

DWC HDPE Pipe – Durable, Cost-Effective Drainage and Conduit Solutions

NewsNov.23,2025

-

HDPE Drainage Pipe – Durable and Sustainable Water Management Solutions

NewsNov.23,2025

-

Durable and Sustainable HDPE Corrugated Pipe Solutions for Modern Infrastructure

NewsNov.23,2025

-

HDPE Water Pipe - Durable, Cost-Effective Water Solutions for Global Needs

NewsNov.22,2025