febr . 12, 2025 00:55 Back to list

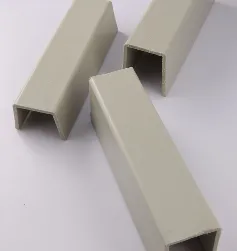

industrial pipe fittings

Industrial pipe fittings play a crucial role in a myriad of sectors, from chemical processing to oil and gas, and even extending to water treatment facilities. Their importance cannot be overstated as they ensure the safe, efficient, and leak-proof transport of fluids across various operations. These components might look small and insignificant individually, but their impact when combined in a piping system is monumental. This article delves into the intricacies of industrial pipe fittings, emphasizing their experience, expertise, authoritativeness, and trustworthiness.

Real-world experience attests to the effectiveness of correctly chosen and installed fittings. Companies sharing testimonials often highlight scenarios where industry-compliant pipe fittings have drastically reduced downtime and maintenance costs. Such firsthand accounts serve as valuable insights for new industries transitioning to more advanced piping systems. For example, a chemical plant might report that using advanced composite fittings significantly lowered the risk of leaks and the need for regular maintenance checks, thereby boosting overall productivity. In terms of authoritativeness, the role of pipe fittings specialists cannot be overemphasized. These experts possess a profound understanding of the intricacies involved in selecting, installing, and maintaining these components. Collaboration with such specialists helps industrial operators avoid common pitfalls and ensures the longevity and efficiency of their piping systems. They provide guidance not only during the selection and installation phase but also throughout the lifecycle of the system, offering maintenance tips and upgrades when necessary. Trustworthiness emerges from consistent performance and compliance with industry standards. Opting for reputed brands that have a track record in delivering quality fittings further instills confidence. These companies often provide certifications, warranty options, and robust customer service, reinforcing their commitment to delivering reliable products. In conclusion, industrial pipe fittings, while simple in appearance, are intricate in their design and application. They require a blend of experience, expertise, authoritativeness, and trustworthiness to choose and implement effectively. By focusing on these elements, industries can ensure their piping systems provide the required performance and reliability, upholding safety and efficiency at all operational levels. This integrated approach not only enhances system performance but also reduces costs and downtime, proving invaluable across industries that rely on complex piping systems.

Real-world experience attests to the effectiveness of correctly chosen and installed fittings. Companies sharing testimonials often highlight scenarios where industry-compliant pipe fittings have drastically reduced downtime and maintenance costs. Such firsthand accounts serve as valuable insights for new industries transitioning to more advanced piping systems. For example, a chemical plant might report that using advanced composite fittings significantly lowered the risk of leaks and the need for regular maintenance checks, thereby boosting overall productivity. In terms of authoritativeness, the role of pipe fittings specialists cannot be overemphasized. These experts possess a profound understanding of the intricacies involved in selecting, installing, and maintaining these components. Collaboration with such specialists helps industrial operators avoid common pitfalls and ensures the longevity and efficiency of their piping systems. They provide guidance not only during the selection and installation phase but also throughout the lifecycle of the system, offering maintenance tips and upgrades when necessary. Trustworthiness emerges from consistent performance and compliance with industry standards. Opting for reputed brands that have a track record in delivering quality fittings further instills confidence. These companies often provide certifications, warranty options, and robust customer service, reinforcing their commitment to delivering reliable products. In conclusion, industrial pipe fittings, while simple in appearance, are intricate in their design and application. They require a blend of experience, expertise, authoritativeness, and trustworthiness to choose and implement effectively. By focusing on these elements, industries can ensure their piping systems provide the required performance and reliability, upholding safety and efficiency at all operational levels. This integrated approach not only enhances system performance but also reduces costs and downtime, proving invaluable across industries that rely on complex piping systems.

Share:

Next:

Latest news

-

Premium Glossy PP Rigid Sheet – Durable & Versatile

NewsAug.07,2025

-

High-Quality HDPE Sheet | Durable Plastic Panels

NewsAug.06,2025

-

High-Precision PVC Rigid Sheets for Vacuum Forming | AI-Optimized

NewsAug.05,2025

-

Durable PVC-M Water Supply Pipes | 60-Year Life

NewsAug.04,2025

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025