As the demand for durable, cost-effective and high-performance piping solutions continues to rise, PVC-M water supply pipe is at the forefront of modern water infrastructure. In this comprehensive guide, we explore the latest industrial trends, manufacturing processes, technical parameters, real-world applications, and how to select or customize the ideal PVC-M water supply pipe solution for your project.

1. Industry Overview & Market Trends

PVC-M water supply pipes represent the next evolution of polyvinyl chloride piping, offering significantly improved impact strength, ductility, and long-term performance compared to conventional PVC-U pipes. According to GVR (2023), the global market for PVC-M pipes in water supply is projected to grow at a CAGR of 6.8% between 2024-2030, driven by urbanization, pipeline upgrades, and stringent water safety regulations.

- Growth Drivers: Rising demand for sustainable and energy-efficient water distribution networks

- Regional Hotspots: Asia-Pacific (especially China & India), Latin America, and Middle East

- Key Industries: Urban/rural water supply, municipal projects, industrial & mining water transmission, irrigation, and replacement of old metal pipes

- Standardization: Adoption of international standards such as ISO 1452-2, ASTM D3139, and BS EN 1452

2. What is PVC-M Water Supply Pipe? (Definition & Structure)

PVC-M water supply pipe (Modified Polyvinyl Chloride) is a non-metallic pressure pipe manufactured by introducing impact modifiers during the polymerization of PVC resin. This modification results in a molecular structure that is both tough and flexible, enabling superior resistance to crack propagation, impact, and external loads.

- Material: High-molecular-weight PVC + impact modifiers (typically CPE, ABS, or rubber-based)

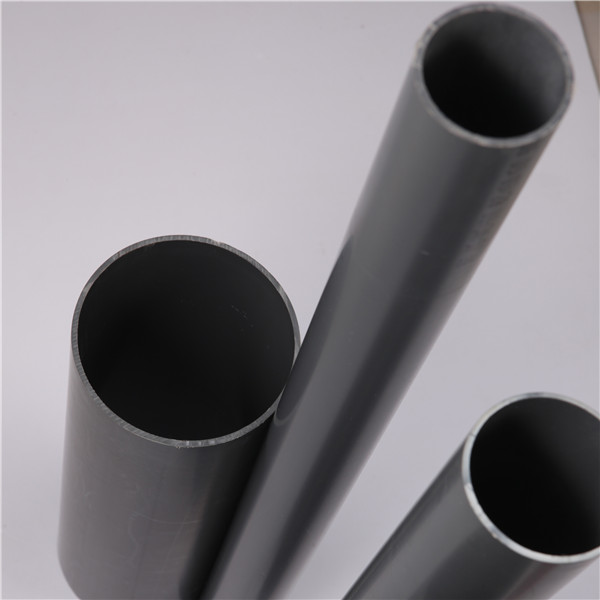

- Color: Blue (potable), light grey, or custom colors

- Main Standard Sizes: DN63–DN630 mm (2.5”–24”), SDR26/SR21/SR17/SR13.6 series

- Pressure Rating: PN6–PN16 Bar (87–232 psi)

- Connection Methods: Socket, solvent-cement, or rubber ring joint

3. Manufacturing Process Flow of PVC-M Water Supply Pipe

The production of PVC-M water supply pipe integrates strict material selection, precise extrusion, and comprehensive quality control. Below is an overview flowchart detailing each critical phase:

Virgin PVC, impact modifiers, stabilizers, pigments

135–150°C dynamic mixing achieves uniform dispersion

Advanced twin-screw extrusion, vacuum calibration

Online water cooling, constant-diameter maintenance

Automatic socket belling or chamfering

Pressure tests, impact tests, dimensional checks (ISO 1452-2)

Bale packing, standard length cutting, warehouse

4. Technical Specifications Table – PVC-M Water Supply Pipe

Below are standard parameters for PVC-M water supply pipe manufactured by Lida Plastic (ISO1452/GB/T5836-2018 compliant).

| Outside Diameter (mm) |

Wall Thickness (mm, SDR21) |

Max. Working Pressure (PN/Bar) |

Unit Length (m/bar) |

Color | Joint Type | Lifespan (Years) |

|---|---|---|---|---|---|---|

| 63 | 3.0 | 8 | 6 / 12 | Blue / Grey | S/Ring | ≥50 |

| 110 | 5.3 | 10 | 6 / 12 | Blue / Grey | S/Ring | ≥50 |

| 160 | 7.7 | 12.5 | 6 / 12 | Blue / Grey | S/Ring | ≥50 |

| 225 | 10.8 | 16 | 6 / 12 | Blue | S/Ring | ≥50 |

| 315 | 15.1 | 16 | 6 / 12 | Blue | S/Ring | ≥50 |

5. Data Visualization – Strength, Longevity & Market Share

6. PVC-M Water Supply Pipe vs. Other Pipes – Technical Comparison

Selecting the right pipe relies on comparing critical features such as mechanical property, durability, chemical stability, and installation costs. The table below summarizes main differences:

| PVC-M | PVC-U | HDPE100 | Ductile Iron | |

|---|---|---|---|---|

| Hydrostatic Strength (50 years, MPa) | 13 | 6 | 8 | --- |

| Impact Toughness (J/m²) | 62–92 | 18–40 | 65–95 | --- |

| Corrosion Resistance | Excellent | Good | Excellent | Poor |

| Prefabrication/Joint Leak Risk | Very Low | Low | Low | High |

| Weight (kg/m for DN200/PN10) | 14 | 16.5 | 20.2 | 51.5 |

| Service Life (Years) | ≥50 | ~40 | ~35 | 30–40 |

| Installation Cost | Low | Low | Medium | High |

7. Application Scenarios – Where Can PVC-M Water Supply Pipe Be Used?

- Urban & rural drinking water transmission (main and branch)

- Municipal water distribution networks

- Agricultural irrigation, horticulture, golf course piping

- Industrial liquid delivery (food & beverage, paper-making, mining)

- Building plumbing, fire protection networks

- Seawater/fertilizer pipe systems (with anti-UV stabilizers)

- Replacement projects for corroded metal or VC pipes

Case Study: Replacement Project for a City Potable Water Network

- Client: Southeast Asian Urban Water Co.

- Year: 2023

- Pipes Used: DN160–DN400, SDR21, 8km total

- Challenge: Frequent leakage and repairs with aging cast iron pipelines under high groundwater tables.

- Solution: Adopted PVC-M water supply pipe – Fast trenchless installation, >50% reduction in joint failure within 1 year, O&M cost lowered by 30%, water loss rate cut to 4% from 12%

Client Feedback: From Industrial Manufacturing Sector

- Industry: Chemical Processing Plant

- Piping: DN225, PN12, 2.5km

- Key Result: No visible scaling/corrosion after 3 years (acidic effluent with pH 4.5–6.2)

— Maintenance Supervisor

8. Technical Advantages of PVC-M water supply pipe

- Superior impact resistance (≥8 times more than PVC-U): Handles site handling, underground stress without fracture

- Outstanding chemical resistance: No rust, no internal scaling, suitable for aggressive/acidic soils and effluents

- Lightweight & easy installation: Cuts labor/hoisting costs by up to 50% compared to ductile iron

- Energy efficiency: Extra smooth wall (Roughness Ra < 0.009 mm) for low friction loss, saving bulking pump power

- Long service life: 50 years + at full working pressure (backed by ISO 1167 Hydro-test data)

- Safe for potable water: No biotoxicity, tested for EN12873, NSF/ANSI 61 certification

9. Leading Manufacturers & Factory Credentials

- Factory/Brand: Lida Plastic (since 2000, ISO 9001/14001 certified)

- Global Collaboration: Projects in 40+ countries, approved suppliers for Veolia, Sinohydro, and Mitsubishi Engineering

- Recognized Quality: ISO 1452, EN 1452, WRAS (UK), NFS

- R&D: 5 patents in modified PVC blends and pipe impact optimization

- OEM/ODM capability: Custom diameter, SDR, color, and print marking service available

Custom Solution / Bulk Supply Service (Factory Direct)

- Custom length spool (up to 16m/bar)

- DN63–DN630 mm, PN6–PN16 Bar (all SDR ratings on request)

- On-site technical consultation and pipeline routing design

- Export packing – seaworthy wrap, container111 loading, 24/7 shipment track

- Optional: Color striping, special end processing, client logo

- Support: ISO, ANSI, FDA, GB, EN and customer standards compliance

Email: sales@lidaplastic.com | WhatsApp: +86-137-0000-0660

10. Delivery & After-Sales

Delivery lead time: 7–15 working days for standard specs, 20–30 days for large projects.

Warranty: 12-year limited warranty + technical support for service life (with ISO 1452 tracking certificates).

After-sales: Onsite guidance, installation manuals, emergency hotline.

Support Documents: Mill test certs, hydraulic proof data, installation guides, third-party lab testing (SGS, BV, CNAS).

11. Frequently Asked Questions (FAQ)

A1: PVC-M water supply pipe uses modified polyvinyl chloride resin with proprietary impact modifiers (ABS, CPE, or MBS), stabilizers, and pigments for improved toughness and chemical resistance.

A2: Main standards are ISO 1452 (Worldwide), EN 1452 (EU), GB/T5836 (China), and AS/NZS 4765 (Australia)

A3: SDR (Standard Dimension Ratio) = Pipe Outer Diameter ÷ Wall Thickness. Lower SDR = thicker wall = higher pressure tolerance. SDR13.6 pipes withstand higher pressure than SDR21 at the same diameter.

A4: Use factory-molded sockets with EPDM rubber rings (factory compliance to EN681-1 for gaskets) and follow ISO installation standards, ensuring axial alignment and correct insertion. Solvent cement joints must use certified adhesives.

A5: Pipes for above-ground or direct sunlight applications are compounded with premium UV stabilizers and titanium dioxide, achieving 4,000+ hours resistance in accelerated aging tests (ASTM G154).

A6: Typically up to 45°C for pressurized flows (ambient), or 60°C for low-pressure applications. Higher temperatures may affect working pressure and long-term strength. For hot water, polyolefin pipes are preferred.

A7: Each production batch is subject to ISO 1452 hydrostatic testing, impact resistance, dimension accuracy checks, and visual inspection. Third-party SGS/BV testing can be provided on request.

12. References and Further Reading

- The Pipe Users Group: "PVC Pipe vs. HDPE Comparison Report"

- ISO 1452-2: "Plastics piping systems for water supply and for buried and above-ground drainage and sewerage"

- Journal of Cleaner Production: "LCA of water supply piping in urban development" (2021)

- Engineering Forums: "PVC-M vs. PVC-U field installation issues"

- World Fluid Mechanics Dictionary: "PVC-M Pipe"