Jul . 25, 2025 07:01 Back to list

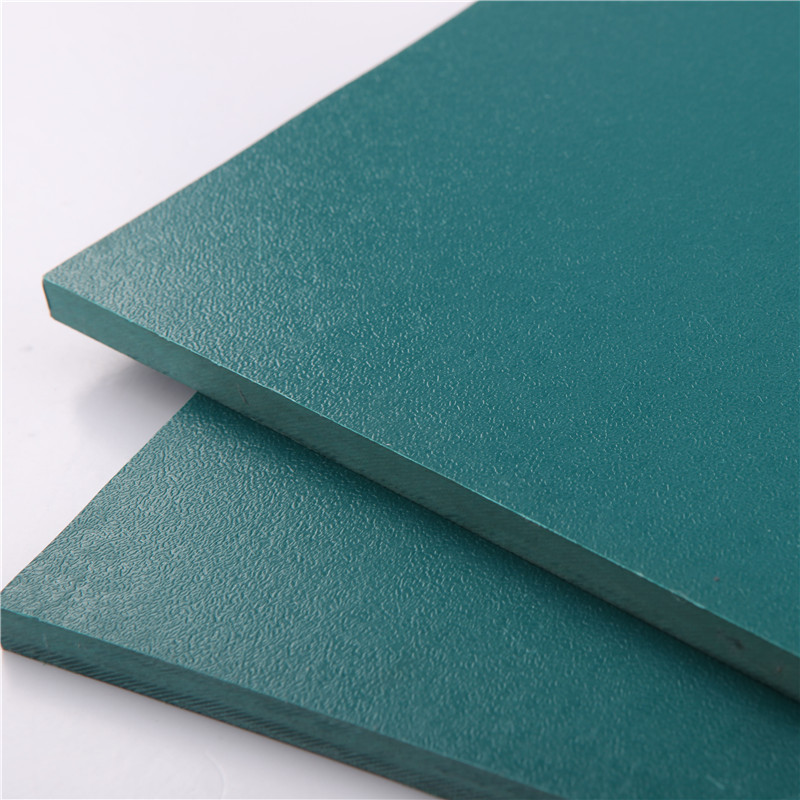

High Quality PVC Rigid Sheet (Embossed Surface) for Industrial Use

Deep Technical Insight and Application Analysis by LIDA Plastic

Contact: Tel: 0086-312-5381013 | Email: lidaplastic@ldsy.cn

Mobile: 0086-17731201156

Address: No.316 Pingan West Street, Shunping County, Baoding City, Hebei, China 072250

The PVC Rigid Sheet (embossed surface) stands at the frontier of polymer material solutions, blending ultra-durable rigid polyvinyl chloride with advanced surface texturing for enhanced performance. In recent industry surveys and technical publications, the demand for high-quality, reliable, and visually distinct rigid PVC sheets has soared across sectors such as construction, chemical containment, signage, and interior design[1]. Global market forecasts point to a steady compound annual growth rate of 4.7% through 2028 in the rigid PVC segment, driven by requirements for superior chemical resistance, surface grip, aesthetic versatility, and easy processability[2].

LIDA Plastic leverages 25+ years of expertise developing and delivering advanced PVC Rigid Sheet (embossed surface) solutions worldwide. With ISO-certified production, a robust R&D workflow, and a commitment to custom engineering, LIDA Plastic sets the industry benchmark for quality, supply reliability, and technical support.

- Short Description: Extruded rigid PVC sheets with deep-embossed texturized surface, delivering mechanical durability, slip resistance, and visual appeal for technical purposes.

- Thickness Range: 3mm ~ 15mm

- Width:

- 1mm~3mm: 1000mm~1300mm

- 4mm~15mm: 1000mm~1500mm

- Length: Any length

- Standard Colors: Dark grey (RAL7011), light grey, black, white, blue, green, red, customizable per requirements

- Surface: Embossed, for anti-slip function and signature appearance.

- For details, visit the product page.

The adoption of PVC Rigid Sheet (embossed surface) in global engineering and architectural applications is supported by several pivotal industry trends:

- Safety & Regulations: Enhanced slip resistance from embossed textures meets stricter safety codes in food processing, laboratories, schools, and cleanrooms.

- Chemical & Weather Resistance: The rigid, non-porous structure of PVC coupled with surface texturing boosts durability in harsh, corrosive, or wet conditions.

- Customization & Branding: Embossing allows unique textures/colors for corporate branding, interior decoration, and anti-forgery security.

- Economics & Sustainability: Rigid PVC panels are cost-effective, recyclable, and facilitate rapid installation and long-term value.

According to the international journal "Polymer-Plastics Technology and Materials", PVC Rigid Sheet (embossed surface) demonstrates superior resistance and performance over other thermoplastics in wet or chemically exposed areas[3].

| Parameter | Typical Value | Test Standard | Industry Range |

|---|---|---|---|

| Thickness | 3mm ~ 15mm | ISO 1183 | 2mm ~ 20mm |

| Width | Up to 1500mm | ASTM D1204 | Up to 1600mm |

| Specific Gravity | 1.42 g/cm3 | ISO 1183 | 1.38 ~1.45 g/cm3 |

| Tensile Strength | ≥52 MPa | ISO 527 | 45~60 MPa |

| Flexural Modulus | 3000 ~ 3200 MPa | ISO 178 | 2500~3500 MPa |

| Heat Distortion Temp. | ≥75°C | ISO 75 | 65~80°C |

| Flame Retardancy | V-0 | UL94 | V-0 ~ V-2 |

| Surface Treatment | Embossed, anti-slip | Custom/LIDA Standard | Varies by OEM |

| Color Availability | Custom | ISO 11664 | Industry Standard Colors |

| Chemical Resistance | Excellent | ISO 2812 | Excellent |

- Wall Cladding and Partitioning: Precise fit, easy cleaning, chemical stability for hospitals, laboratories, and commercial buildings.

- Chemical Containment: Outstanding corrosion resistance and minimal permeability, ideal for tanks, ducts, and process linings.

- Cleanroom Environments: Low dust emission, easy-to-disinfect, and anti-slip characteristics, fitting food & pharma industries.

- Signage, Displays, and Branding: Surface embossing for tactile or aesthetic effect and printability.

- Automotive & Mass Transit: Durable vehicle wall floor/deck protection, with enhanced slip protection and design options.

- Floors, Doors, and Safety Zones: Certified slip resistance for traffic corridors, safety doors in factories, or public buildings.

- Industrial Linings: Thermal and structural stability for machine guards and equipment housing.

- Proven Track Record: 25+ years supplying advanced rigid PVC solutions to multinationals and innovation-driven sectors.

- ISO Certification & Quality: Full process ISO9001 quality control, documented batch traceability.

- Advanced Embossing Technology: In-house tools for custom motifs with consistent depth and texture.

- Expert Technical Support: End-to-end project assistance, from material selection through fabrication and installation.

- Fast Global Delivery: Strategic production in China with robust logistics for export.

- Sustainability: Products made from eco-friendly, recyclable PVC grades, minimizing environmental impact.

Call: 0086-312-5381013 Mobile: 0086-17731201156

Email: lidaplastic@ldsy.cn

Website: www.lidaplastic.com

Address: No.316 Pingan West Street, Shunping County, Baoding City, Hebei, China 072250

- "Global Rigid PVC Sheets Market: Growth, Trends, COVID-19 Impact, and Forecasts (2023-2028)", Market Research Future, retrieved Jun 2024.

- "Polyvinyl Chloride (PVC) – A Practical Review of Mechanical Properties", Polymer Database, referenced Jun 2024.

- "Embossed Polyvinyl Chloride Sheets for Improved Mechanical and Chemical Resistance", Polymer-Plastics Technology and Materials Journal, 2024.

- "Slip Resistance and Safety in PVC Flooring", Floor Covering News, 2022.

- Technical Discussions on PlasticsPNews Forum, 2024.

- "Effect of Surface Embossing on Polymeric Sheet Properties", Journal of Applied Polymer Science, 2024.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025