Product introduction

Polyvinyl chloride (PVC) natural color is yellow translucent, shiny. Transparency is better than polyethylene, polypropylene, poor in polystyrene, with the dosage of different additives, divided into soft and hard polyvinyl chloride, soft products soft and tough, feel sticky, hard products hardness is higher than low density polyethylene.

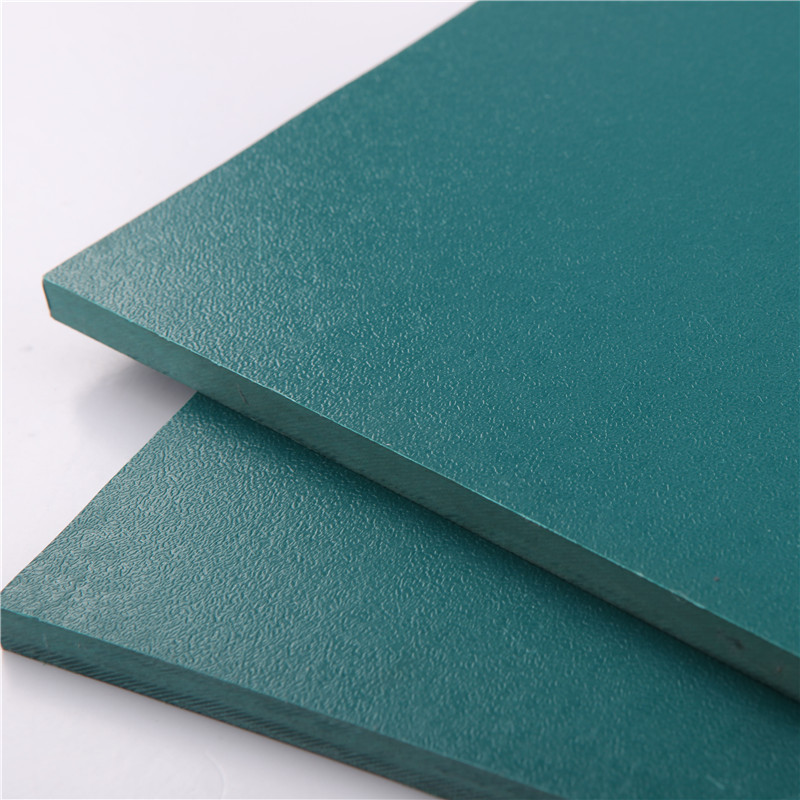

PVC rigid sheet is PVC after extrusion processing from the hard products.

Production process

PVC board is polyvinyl chloride (PVC) plastic by free radical polymerization of vinyl chloride monomer polymer, English name is Polyviny chloride, PVC for short. PVC board is added in the PVC stabilizer, lubricant and filler, after mixing, with the extruder extruded of various thickness of hard.

PVC rigid sheet embossed sheet has excellent corrosion resistance, insulation, and a certain mechanical strength; After the secondary processing can be made into sulfuric acid (hydrochloric acid) tank (bucket box); Processing products of templates, decorative boards, exhaust pipes, equipment lining and other special-shaped products, containers. It is an ideal material for chemical industry, building materials, decoration and other industries.

Applications

PVC rigid sheets with embossed surfacceare are widly used for inside and outside constructions, general and chemical industries, such as signboards for advertisement, wall cladding of office and public utilities, door panels, Lab equipment, Etching equipment, Semiconductor processing equipment, water tank, chemical storing tank, oil tank, storing tank for brewing water, acid or alkali production tower, acid or alkali washing tower, photograph developing instruments. Electrical industries for battery box, electrometer plate, electrolytic tank and various plates for electrical insulation and so on.