Oct . 10, 2025 09:30 Back to list

PVC Grey Sheet for Extraction—Acid-Resistant, FR, UV Safe?

PVC Grey Sheet for Extraction: What Pros Are Buying in 2025

In fume handling and gas scrubber projects, the quiet hero is often the sheet material. The PVC grey sheet for extraction has become a go‑to for fabrication shops and EPC contractors who want robust, weldable plastics that don’t fight back during installation. Honestly, I’ve watched buyers switch from FRP to rigid PVC-U simply because installations became faster and maintenance less dramatic.

What’s Trending

Environmental compliance is tightening—more acid mist, chlorine, and solvent capture lines than ever. Plants want materials that resist corrosives, meet RoHS/REACH, and can be hot‑gas welded onsite. It seems that PVC grey sheet for extraction hits a sweet spot: chemical resistance, decent temperature range, and repeatable fabrication. Many customers say the predictable weld quality is the clincher.

Key Specifications

| Thickness | 1–60 mm |

| Width by thickness | 1–3 mm: 1000–1300 mm; 4–20 mm: 1000–1500 mm; 25–30 mm: 1000–1300 mm; 35–60 mm: 1000 mm |

| Length | Any length; standard 1220×2440, 1000×2000, 1500×3000 mm |

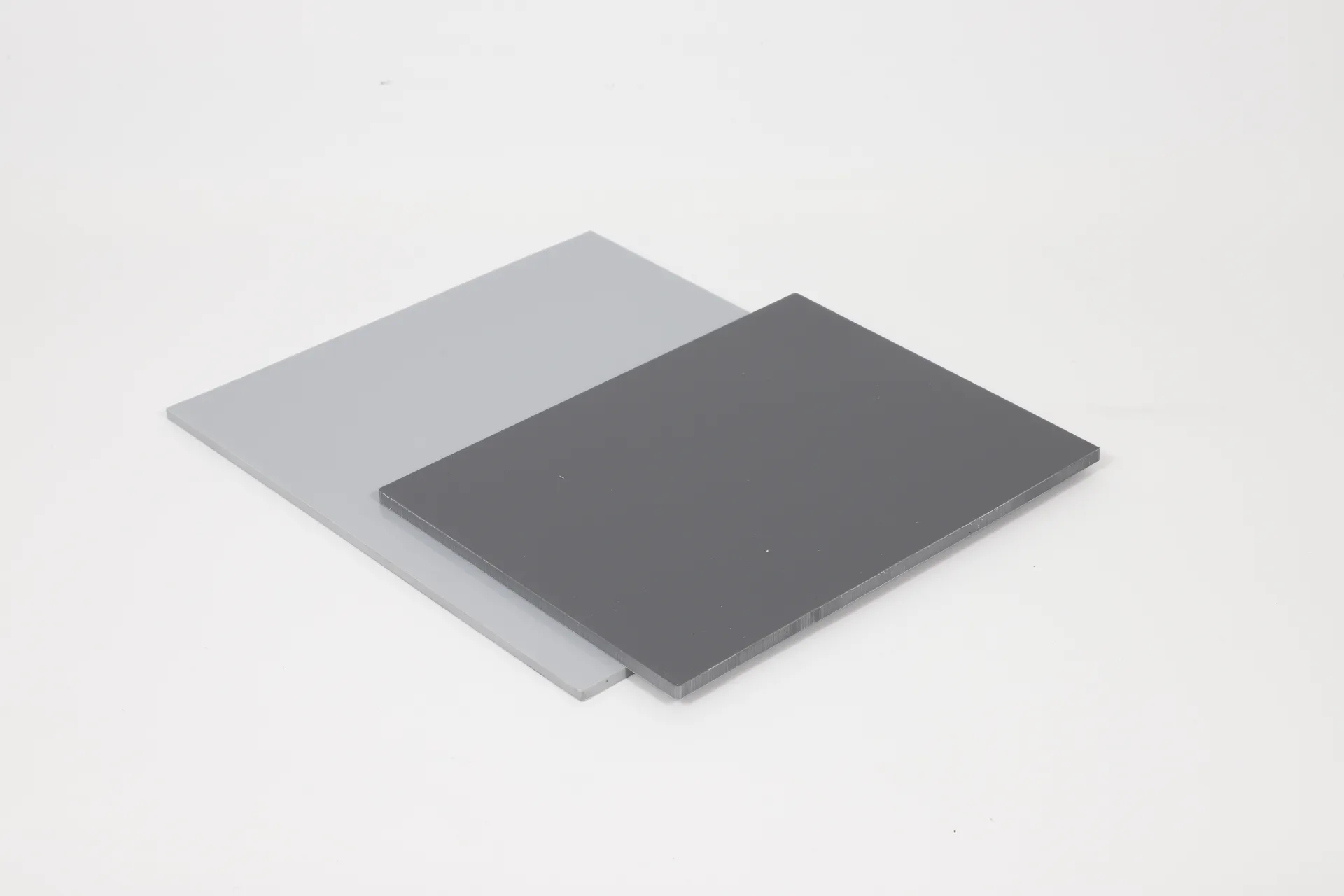

| Surface / Colors | Glossy; RAL7011 dark grey, light grey, black, white, blue, green, red, custom |

| Typical properties (≈) | Density 1.40–1.46 g/cm³; Tensile 45–55 MPa (ISO 527); Shore D 80–85; Vicat B50 75–80°C (ISO 306); UL 94: V‑0/V‑2 depending on grade |

| Service life (real-world) | Indoor extraction: 8–15 years; Outdoor with UV stabilization: 5–10 years |

Process Flow, Materials, and Testing

Materials: PVC-U resin (no plasticizer), Ca‑Zn stabilizers, impact modifiers, pigments. Methods: extrusion or calendaring, cooling, trimming, stress‑relief conditioning. Fabrication: CNC cutting, hot‑gas welding, thermoforming, bending, solvent bonding (where appropriate—test for stress crazing).

Testing standards typically used: ISO 527 (tensile), ISO 178 (flexural), ISO 179/180 (impact), ISO 306 (Vicat), UL 94 (flammability), dimensional tolerances per ISO 2768‑m, chemical resistance per ISO/TR 10358 guidance. Compliance: RoHS and REACH. Batch certificates are common—and customers increasingly ask for them.

Where It Works Best

- Fume extraction ducting, scrubber internals, plenum linings

- Electroplating lines (HCl, H2SO4, HNO3 vapors), pickling shops

- Laboratory extraction benches, exhaust hoods, fan housings

- Battery recycling, semiconductor wet benches (check compatibility)

Feedback is consistent: PVC grey sheet for extraction welds cleanly, holds fasteners well, and resists common acids/alkalis. Temperature wise, keep continuous use under ~60°C for best dimensional stability.

Vendor Snapshot (quick reality check)

| Vendor | Lead time | Certifications | MOQ | Notes |

|---|---|---|---|---|

| Lida Plastic (Hebei, China) | 7–15 days typical | RoHS/REACH declarations; test reports on request | Flexible | Custom colors/sizes, CNC-ready sheets |

| Generic Importer | 3–6 weeks | Basic compliance | Pallet | Cost-driven, fewer customization options |

| EU Supplier | 2–4 weeks | Extensive lab testing | Moderate | Premium pricing, strong documentation |

Customization and Real Projects

Options include cut‑to‑size, CNC patterns, butt‑ and fillet‑welded panels, thermoformed elbows, and color matches. A recent plating plant retrofit I visited swapped corroded steel liners for PVC grey sheet for extraction: VOC capture improved by ~12% (better duct sealing), and maintenance calls dropped sharply in the first six months—surprisingly fast payback.

Sourcing Note

Origin: No.316 Pingan West Street, Shunping County, Baoding City, Hebei, China 072250. If you need thick gauges (35–60 mm) for base plates or scrubber baffles, ask for flatness and residual stress data—real‑world use may vary by batch, and it’s worth checking.

Standards and Documentation

Look for test data aligned to ISO 527/178/306, UL 94, and RoHS/REACH declarations. For ductwork, coordinate with your local mechanical code and fan manufacturer’s max operating temperatures. To be honest, the paperwork matters as much as the plastic when inspectors show up.

Authoritative citations

- ISO 527: Plastics—Determination of tensile properties.

- ISO 178: Plastics—Determination of flexural properties.

- ISO 306: Plastics—Thermoplastic Vicat softening temperature.

- UL 94: Tests for flammability of plastic materials.

- ASTM D1784: Rigid Poly(Vinyl Chloride) (PVC) Compounds and Chlorinated PVC (CPVC) Compounds.

- Directive 2011/65/EU (RoHS) and amendments.

- Regulation (EC) No 1907/2006 (REACH).

-

Comprehensive Guide To HDPE Pipes and Fittings | Durable & Sustainable Solutions

NewsNov.24,2025

-

HDPE Culvert Pipe – Durable, Flexible & Sustainable Infrastructure Solutions

NewsNov.24,2025

-

DWC HDPE Pipe – Durable, Cost-Effective Drainage and Conduit Solutions

NewsNov.23,2025

-

HDPE Drainage Pipe – Durable and Sustainable Water Management Solutions

NewsNov.23,2025

-

Durable and Sustainable HDPE Corrugated Pipe Solutions for Modern Infrastructure

NewsNov.23,2025

-

HDPE Water Pipe - Durable, Cost-Effective Water Solutions for Global Needs

NewsNov.22,2025