Oct . 27, 2025 05:20 Back to list

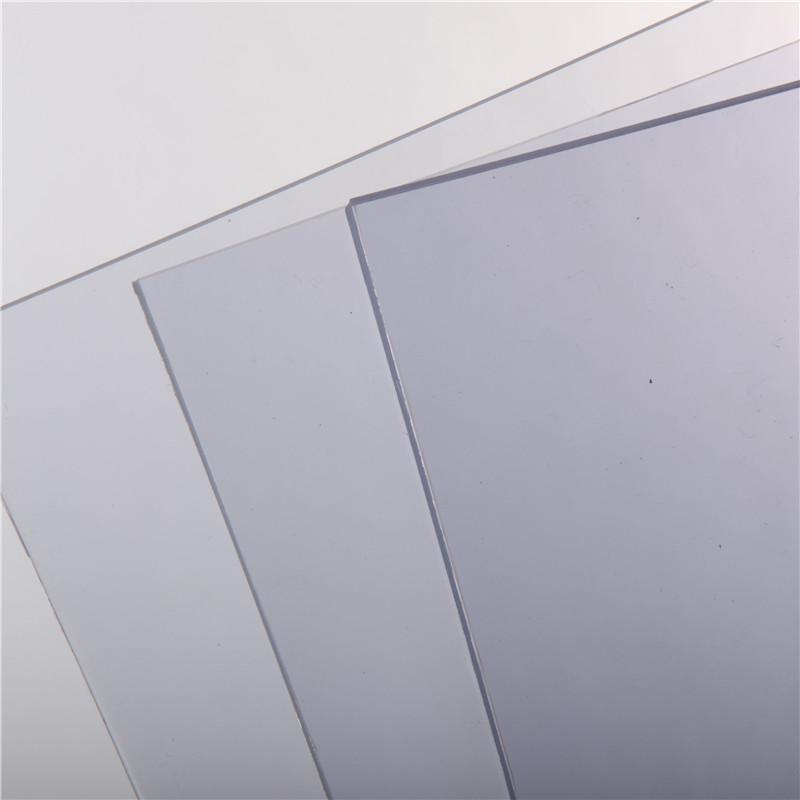

PVC Clear Sheet | Clarity, Impact Resistant, Custom Sizes

PVC Clear Sheet is a key solution in the manufacturing industry, specifically within plastic product industry and Manufacturing of plastic boards, sheets, and films. This article explores how Baoding Lida Plastic Industry Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- PVC Clear Sheet Overview

- Benefits & Use Cases of PVC Clear Sheet in Manufacturing of plastic boards, sheets, and films

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on PVC Clear Sheet from Baoding Lida Plastic Industry Co., Ltd

PVC Clear Sheet Overview

PVC clear sheet is a transparent, rigid or semi-rigid thermoplastic substrate engineered for visibility, durability, and consistent processing performance. In the plastic product industry and across the Manufacturing of plastic boards, sheets, and films, it serves as a versatile base material for printing, laminating, thermoforming, die-cutting, and protective glazing. Decision makers choose PVC clear sheet for its balanced clarity, dimensional stability, chemical resistance, and cost-effectiveness, especially when high optical quality and reliable downstream convertibility are priorities.

- Relevance: Ideal for window cartons, signage overlays, machine guards, display components, and surface protection in continuous or batch production lines.

- Technical background: Available in rigid and semi-rigid grades, with options for gloss or matte surfaces, protective masking, UV-stabilized or anti-static formulations, and printable surfaces compatible with common inks. Precise gauge control helps reduce scrap and ensures consistent converting results.

- Manufacturing assurance: Baoding Lida Plastic Industry Co., Ltd provides stable quality, customizable dimensions, and responsive lead times—critical factors for OEMs and converters scaling production with predictable yields.

Benefits & Use Cases of PVC Clear Sheet in Manufacturing of plastic boards, sheets, and films

From high-visibility packaging to protective panels, PVC clear sheet integrates smoothly into multiple production workflows. Converters value its clean die-cuts, stable lay-flat, and predictable thermoforming behavior, while brand owners appreciate its clarity and printability for premium presentation. In continuous-sheet manufacturing, it functions as a durable overlay or interlayer, and in film/board operations, it acts as a robust surface protector or structural component.

- Applications: packaging windows, clamshells and trays, machine covers, signage and display backers, face shields and dividers, label and card carriers, and printable graphics substrates.

- Competitive advantages: excellent optical clarity, good chemical resistance, inherent flame performance compared with many polyolefins, and a favorable strength-to-weight ratio. Consistent gauge and surface finish support reduced rework, faster press speeds, and reliable adhesion in printing and lamination.

- Supplier capability: Baoding Lida Plastic Industry Co., Ltd tailors specifications—grade, finish, dimensions, protective films—to your process, helping teams minimize changeovers and maintain repeatable quality across large runs.

Cost, Maintenance & User Experience

Total cost of ownership for PVC clear sheet is shaped by yield, throughput, and long-term performance. Thanks to consistent thickness and surface quality, converters often experience fewer adjustments on presses and cutting lines, which can translate into improved uptime and lower scrap. The material’s robust surface—often supplied with removable protective masking—reduces handling defects and supports clean, saleable parts with minimal finishing steps.

- Durability and ROI: Reliable clarity, dimensional stability, and compatibility with common fabrication methods help protect margins. Many users report smoother printing and laminating performance, which supports faster cycle times and consistent brand presentation.

- Maintenance: For best appearance, clean with mild soap and water using a soft, non-abrasive cloth; avoid harsh solvents unless validated in your process. Store flat, protected from dust and direct sunlight until use to maintain optical quality.

Sustainability & Market Trends in manufacturing

Sustainability conversations in plastics center on material efficiency, recyclability, and responsible sourcing. In industrial settings, PVC clear sheet can support waste reduction through precise gauge control, high yields, and the potential to reclaim clean edge trims where local recycling streams permit. Market trends show growing demand for transparent protective panels, high-clarity packaging windows, and printable substrates compatible with digital and UV-curable inks—areas where PVC clear sheet is well-established.

- Regulatory and growth factors: Producers and brands are aligning with evolving compliance and extended producer responsibility frameworks, while seeking materials that deliver performance with minimized waste.

- Forward-thinking supplier: Baoding Lida Plastic Industry Co., Ltd focuses on process efficiency and quality consistency, and can discuss options to support your sustainability goals—such as optimized thickness for material savings and best practices for responsible handling and recycling within your region.

Conclusion on PVC Clear Sheet from Baoding Lida Plastic Industry Co., Ltd

PVC clear sheet delivers the balance B2B decision makers need: optical clarity, reliable processing, and robust performance across packaging, protection, and display applications in the Manufacturing of plastic boards, sheets, and films. With dependable quality and customizable options, Baoding Lida Plastic Industry Co., Ltd is a trusted partner for OEMs and converters seeking scale, speed, and consistency. Ready to qualify the material for your next run? Contact us: email: lidaplastic@ldsy.cn — Visit our website: https://www.lidaplastic.com

-

Comprehensive Guide To HDPE Pipes and Fittings | Durable & Sustainable Solutions

NewsNov.24,2025

-

HDPE Culvert Pipe – Durable, Flexible & Sustainable Infrastructure Solutions

NewsNov.24,2025

-

DWC HDPE Pipe – Durable, Cost-Effective Drainage and Conduit Solutions

NewsNov.23,2025

-

HDPE Drainage Pipe – Durable and Sustainable Water Management Solutions

NewsNov.23,2025

-

Durable and Sustainable HDPE Corrugated Pipe Solutions for Modern Infrastructure

NewsNov.23,2025

-

HDPE Water Pipe - Durable, Cost-Effective Water Solutions for Global Needs

NewsNov.22,2025