Oct . 18, 2025 14:20 Back to list

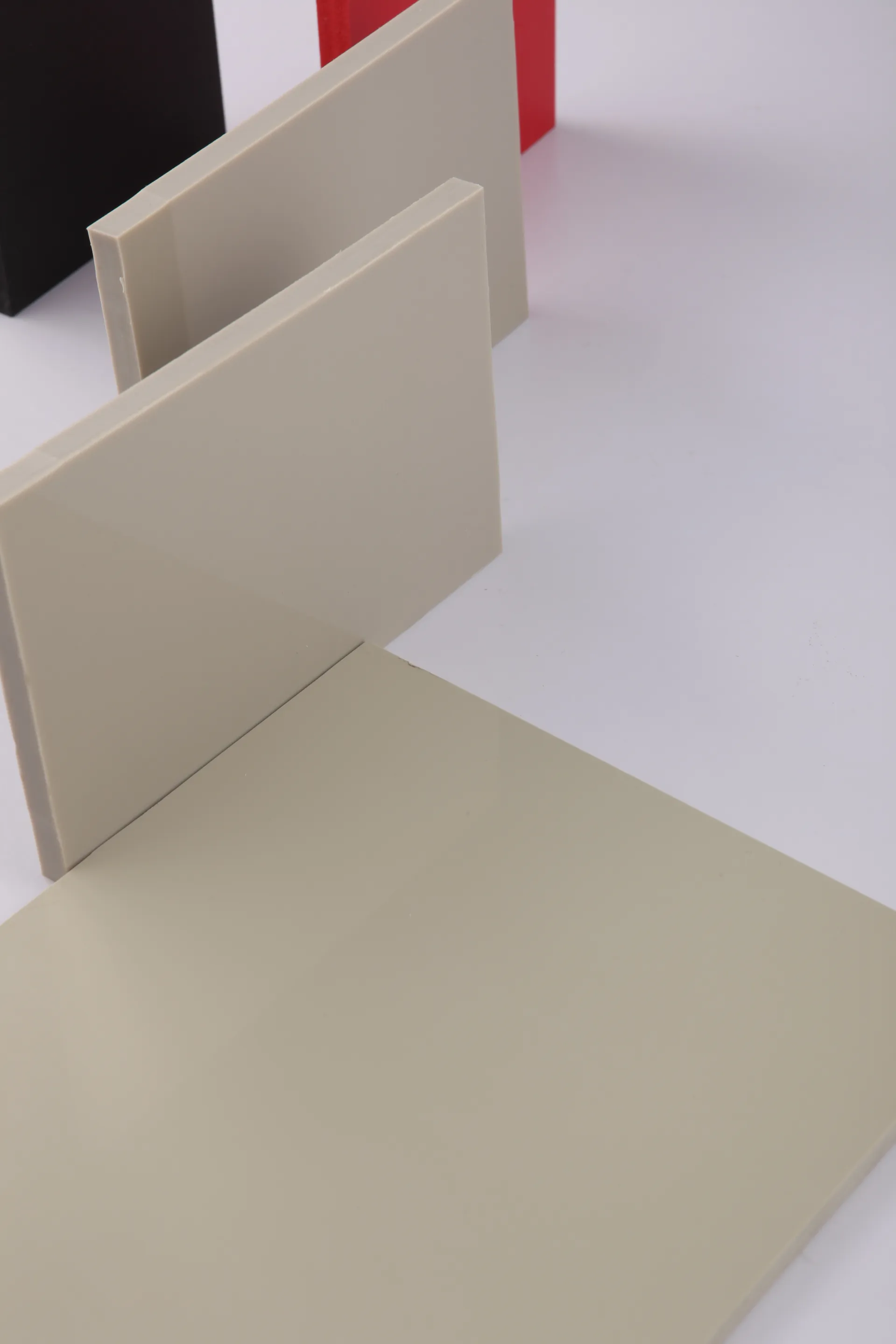

PP Fire Retardant Sheet UL94 V-0 | Halogen-Free, RoHS

PP Fire Retardant Sheet: What Buyers Are Really Asking in 2025

When engineers ask about the PP fire retardant sheet, they usually want three things: reliable flame performance, consistent machinability, and proof it won’t crack or warp after a year in service. To be honest, that’s exactly where this material has matured. The newest grades balance UL 94 ratings with good stiffness and clean processing, and—surprisingly—remain price-friendly versus PC or PVDF in many enclosures.

Industry Trends (Short Version)

- Shift to halogen‑free packages for sustainability and RoHS/REACH comfort.

- Higher LOI and better V-0 retention at thinner gauges, thanks to synergistic FR systems.

- EV battery protection, lab furniture, and cleanroom liners are driving demand.

Product Snapshot and Sizes

LIDA’s PP fire retardant sheet ships from No.316 Pingan West Street, Shunping County, Baoding City, Hebei, China 072250. Thickness: 2–30 mm. Standard sheets: 1220×2440 mm, 1000×2000 mm, 1500×3000 mm. Cut-to-size? Yes, routinely. Surfaces: glossy or embossed. Colors: natural, grey (≈RAL7032), black, plus custom matches.

Technical Specifications (typical, real-world use may vary)

| Property | Typical Value | Test/Standard |

|---|---|---|

| Density | ≈0.95 g/cm³ | ISO 1183 |

| Flame rating | UL 94 V‑0 @ 3.0 mm; V‑2 @ 1.5 mm (typ.) | UL 94 [1] |

| Limiting Oxygen Index (LOI) | ≈26–30% | ISO 4589 |

| Vicat softening temp | ≈150 °C (A120) | ISO 306 [2] |

| Tensile strength | ≈28 MPa | ISO 527 |

| Notched Charpy | ≈7 kJ/m² | ISO 179 |

| FMVSS 302 | Pass (typ. ≥3 mm) | FMVSS 302 [3] |

| Service temperature | -20 to +100 °C | Internal qualification |

Process Flow, Materials, and Testing

Materials: PP homopolymer or impact-copolymer + halogen‑free FR package (often ammonium polyphosphate systems with synergists), antioxidants, UV stabilizers on request. Methods: dry-blend → twin-screw compounding → sheet extrusion/calendaring → annealing → cut-to-size. Testing: UL 94, LOI, FMVSS 302/ISO 3795, Vicat, tensile/impact, and glow-wire/needle flame for select programs (IEC 60695 [4]). Typical service life: ≈8–15 years indoors; outdoors depends on UV package.

Applications We See Most

- Electrical cabinets, battery module barriers, cable trays.

- Laboratory benches, fume hood liners, cleanroom wall cladding.

- Automotive interior panels and HVAC housings (FMVSS 302).

- Equipment covers, machine guards, chemical handling bins.

Customer feedback: machinists like the “clean chip” behavior; purchasing likes the stable lead times. Some note embossed surfaces hide scuffs in factory environments—handy tip.

Vendor Comparison (quick take)

| Vendor | UL Rating (typ.) | Cut-to-Size | Lead Time | Custom Colors | Notes |

|---|---|---|---|---|---|

| LIDA Plastic (Hebei, CN) | V‑0 @ 3 mm | Yes | ≈10–20 days | Yes | ISO 9001; RoHS/REACH support |

| Generic Importer | V‑2 @ 3 mm | Limited | ≈3–6 weeks | Maybe | Specs vary by batch |

| Premium EU Brand | V‑0 @ 1.5–3 mm | Yes | ≈2–4 weeks | Yes | Higher price, excellent data set |

Customization and Real Cases

Options: halogen‑free vs. traditional FR, UV package, anti-static, emboss depth, and tight thickness tolerances for CNC nests. A battery integrator recently switched to PP fire retardant sheet for module partitions—cut weight by ~18% versus PC while meeting V‑0. Another win: a pharma fit-out used grey embossed PP fire retardant sheet for cleanroom cladding; easy wipe-down and no rust, obviously.

Compliance/certs on request: UL 94 classification, ISO 9001 QA, RoHS/REACH declarations, and—if the RFQ demands—material data with traceable batch testing. If you need pre-cut kits, just share DXFs; the team can nest for yield.

Bottom line

If your spec calls for tough, machinable sheets with credible fire data, PP fire retardant sheet hits a sweet spot of cost, weight, and compliance. Not perfect for high-heat continuous use—be realistic—but a workhorse for enclosures, labs, and transport interiors.

References

-

Efficient HDPE Pipe Drip Irrigation Systems for Sustainable Farming

NewsNov.21,2025

-

HDPE Rain Pipe Solutions: Durable & Sustainable Rainwater Management

NewsNov.20,2025

-

HDPE Pipe for Drip Irrigation – Sustainable Water Solutions for Agriculture

NewsNov.20,2025

-

Durable and Efficient Sprinkler HDPE Pipe Solutions for Global Water Management

NewsNov.19,2025

-

Durable and Efficient HDPE Irrigation Pipe Fittings for Sustainable Water Management

NewsNov.19,2025

-

Efficient and Durable HDPE Pipe Sprinkler Systems for Modern Irrigation

NewsNov.18,2025