Aug . 01, 2025 00:20 Back to list

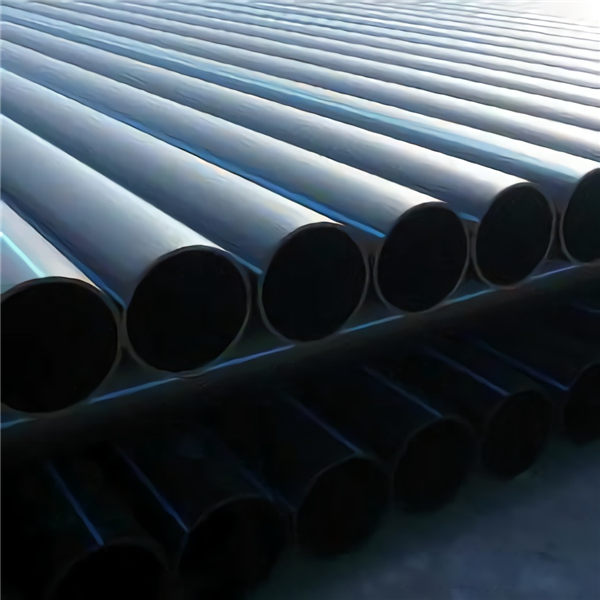

HDPE Drainage & Irrigation Pipe - Durable, Efficient Solutions

The market for HDPE drainage and irrigation pipe systems has observed robust growth, driven by urban development, infrastructure modernization, and sustainable water management initiatives worldwide. According to MarketsandMarkets (2023), the global HDPE pipes market size is projected to reach $23.2 Billion by 2027, growing at a CAGR of 5.7% from 2022 (source). Key industries—municipal waterworks, agriculture, petrochemicals, and industrial processing—are increasingly choosing HDPE for its durability, chemical resistance, and cost-efficiency.

HDPE drainage and irrigation pipe is fabricated from premium High-Density Polyethylene granules, offering:

- High tensile strength for pressure tolerance

- Excellent flexibility—minimizing joint fatigue

- Superior chemical & corrosion resistance against most acids, bases, and salts

- Complies with international standards (ISO 4427, EN 12201, ASTM F714, ANSI/AWWA C901/C906)

| Specification | HDPE Pipe | PVC Pipe | Steel Pipe |

|---|---|---|---|

| Material | High-Density Polyethylene (PE100/PE80) | Unplasticized Polyvinyl Chloride | Carbon Steel (Q235, Q345B) |

| Standard | ISO 4427/EN 12201/ASTM F714 | ISO 1452/ASTM D1785 | API 5L/ASTM A53 |

| Max Operating Pressure (MPa) | 0.6–2.0 | 0.4–1.6 | ≥2.5 |

| Temperature Range (°C) | -40 to +60 | 0 to +60 | -30 to +100 |

| Corrosion Resistance | Excellent | Good (not against solvents/oils) | Poor, needs lining/coating |

| Longevity (Years) | ≥50 | 20–30 | 20–40 |

| Jointing Method | Butt Fusion, Electrofusion, Socket | Solvent Welding, Rubber Ring | Welding, Flange, Threaded |

| Eco Friendliness | 100% recyclable | Partially recyclable | Recyclable, but energy intensive |

The production of HDPE drainage and irrigation pipe typically follows a precise extrusion and finishing workflow that ensures product consistency, performance, and compliance with ISO standards:

- Raw Material Selection: Strictly sourced PE100/PE80 granules (resin) conforming to ISO 4427 material requirements.

- Feeding & Melting: Granules are fed into an automated extruder and melted at controlled temperatures (180-240°C) for uniformity.

- Extrusion & Die Shaping: Molten HDPE is forced through a pipe die and mandrel, forming the desired diameter and wall thickness.

- Vacuum Sizing & Cooling: Pipes enter a vacuum tank for precise diameter control, then are rapidly cooled with water sprays to solidify structure.

- CNC Cutting: High-speed CNC saws cut pipes to length (standard: 6m or 12m, custom available).

- Quality Testing: Every batch undergoes:

- Hydrostatic pressure test (ISO 1167)

- Dimensional inspection (ISO 3126)

- Impact and slow crack growth testing (ISO 13479, ISO 9080)

- Marking & Packing: Pipes are laser-marked for traceability and prepared for shipment.

The advanced use of automated systems and online sensors guarantees each HDPE drainage and irrigation pipe meets stringent global standards (ISO, ANSI). Typical Lifespan: 50+ years under recommended operating conditions.

In terms of performance vs. cost, HDPE drainage and irrigation pipe demonstrates a 30–50% lower total cost of ownership over 30 years versus steel or reinforced concrete piping. Fewer joints, fusion welding, and corrosion resistance drastically reduce maintenance. Plus, the smooth bore ensures low friction headloss—cutting pumping energy demands by 10% or more in irrigation networks.

HDPE drainage and irrigation pipe is available in standard and custom specifications:

- Nominal Diameter: DN20–DN1600 mm

- Pressure Classes: PN6, PN8, PN10, PN12.5, PN16, PN20

- Wall Thickness: SDR41–SDR9 (customizable)

- Color: Black with blue/green/red stripes; UV stabilized

- Jointing Options: Butt fusion, electrofusion coupler, flange, spigot

- Hydraulic design optimization

- Layout & stress analysis with BIM/CAD

- Field installation supervision

- On-site or remote training for fusion welding

Warranty: 50 years for material durability under standard conditions.

Support: 24/7 technical hotline; on-site service on request; full documentation and compliance certificates provided with each shipment.

HDPE drainage and irrigation pipe has proven excellence in the following sectors:

- Agricultural irrigation networks: High UV and corrosion resistance ensures sustainable water supply over decades.

- Municipal stormwater drainage: Large diameter (up to DN1600mm) options handle peak flows effortlessly.

- Underground fire water and potable pipelines: Certified food-grade HDPE; jointless design minimizes leak risk.

- Industrial effluent, mining, and chemical transport: Inert to strong acids/alkalis; fusion joints prevent chemical seepage.

Deployed over 120 km of HDPE drainage and irrigation pipe (DN315/DN450) to replace aging steel. Achieved 30% water saving, zero leaks (24 months), and 18% pumping energy reduction validated by the Ministry of Water Resources. Locally trained teams performed fusion welding with ISO/TS 22391 oversight.

Installed 5.2km of DN800 HDPE piping in refinery zones. Passed all BV/SGS inspection protocols; outperforms prior ductile iron pipes in corrosion and hydraulic performance.

Municipal flood alleviation project chose HDPE drainage and irrigation pipe for rapid installation and life-cycle cost savings. Minimal joints and high flexibility allowed for trenchless deployment under city roads, cutting disruption and project time by 41%.

User feedback: Engineers appreciate HDPE’s light weight, jointing efficiency, and minimal maintenance. End-users note steady flow rates after years of use and zero scale build-up.

Frequently Asked Questions

A: Selected High-Density Polyethylene (HDPE) resin, typically PE100 (preferred for strength and longevity) or PE80, conforming to ISO 4427 standards.

A: Butt fusion welding and electrofusion couplers are the industry standards, providing robust leak-proof joints. Flange and spigot connections are available for integration with other materials.

A: Pressure classes range from PN6 to PN20 (0.6~2.0 MPa) as per ISO 4065. SDR (Standard Dimension Ratio) is used to correlate pressure capacity with wall thickness.

A: ISO 4427 (water), EN 12201 (Europe), ASTM F714 (USA), and ANSI/AWWA C906 (potable water). Industry certification ensures global acceptance.

A: Exceeding 50 years under recommended pressure/temperature, with minimal loss in hydraulic performance or structural integrity.

A: Yes, it is highly resistant to most chemicals, including acids, alkalis, brine, and many hydrocarbons. Always reference the chemical compatibility chart for specialty fluids.

A: HDPE is fully recyclable, non-toxic, offers low carbon footprint in production and transport, and is RoHS/REACH compliant.

- Production Time: 7–20 days for standard specifications, fast track for urgent projects

- Warranty: 50 years on material integrity under ISO conditions

- Customer Service: 24/7 multilingual support, on-site training and supervision, video & documentation library, instant WhatsApp/WeChat/Email response channels

- Certificates: Supplied with ISO/EN/ASTM/ANSI certificates, third-party test reports, and full traceability

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025