Th6 . 06, 2025 14:25 Trở lại danh sách

HDPE Sheet: Durable, Versatile, and Eco-Friendly Plastic for All Applications

In modern construction, manufacturing, and fabrication industries, the demand for high-performance materials is on the rise. One such material that has gained widespread popularity is the tấm nhựa HDPE. Known for its strength, chemical resistance, and flexibility, High-Density Polyethylene (HDPE) has become a preferred plastic material across countless applications.

From packaging and automotive components to marine construction and DIY projects, HDPE plastic sheets offer outstanding benefits. This article explores what makes HDPE a standout option, offers insights into cutting HDPE sheets, and highlights the growing importance of recycled HDPE sheets in sustainable production.

What Is an HDPE Sheet?

An tấm nhựa HDPE is a flat, rigid panel made from High-Density Polyethylene—a thermoplastic polymer with a high strength-to-density ratio. It is well-regarded for its resistance to moisture, impact, UV rays, and various chemicals, making it an incredibly versatile material.

HDPE plastic sheets are used in industries such as:

Construction

Food processing

Marine and boating

Agriculture

Bao bì

Fabrication and prototyping

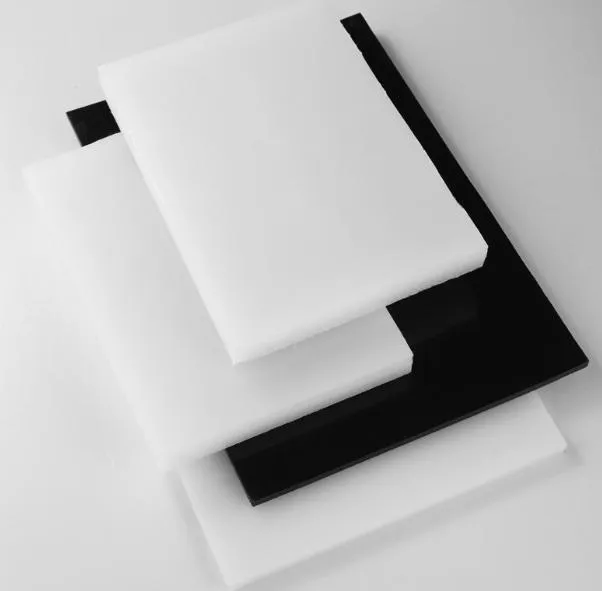

They come in a variety of thicknesses, sizes, and colors, including natural, black, and custom-colored options.

Benefits of Using HDPE Plastic Sheets

Choosing HDPE plastic sheets for your projects provides several significant advantages:

1. Durability

HDPE is incredibly tough and long-lasting. It doesn’t crack, chip, or degrade easily, even under heavy loads or in outdoor environments.

2. Weather and UV Resistance

HDPE resists UV rays, moisture, and fluctuating temperatures. This makes it perfect for outdoor use, such as signage, playground equipment, and boat components.

3. Chemical Resistance

It does not corrode or react with most industrial chemicals, making HDPE plastic sheets suitable for chemical storage and piping systems.

4. Lightweight and Flexible

Despite its strength, HDPE is lightweight and flexible, allowing for easy handling, transport, and shaping.

5. Food-Safe

Many HDPE sheets are FDA-approved, making them ideal for use in food preparation surfaces, cutting boards, and storage containers.

Cutting HDPE Sheets: What You Need to Know

One of the major appeals of HDPE is its ease of fabrication. Whether you're working on a DIY project or manufacturing industrial components, cutting HDPE sheets is straightforward with the right tools.

Recommended Tools:

Circular saw with a fine-tooth blade

Jigsaw for curved cuts

Table saw for precision straight cuts

Utility knife (for thin sheets only)

Cutting Tips:

Mark your cut line clearly with a permanent marker or scribe.

Use clamps to hold the sheet steady during cutting.

Run the saw at a medium speed to avoid melting or rough edges.

Deburr edges with sandpaper or a file for a clean finish.

With the proper tools and techniques, cutting HDPE sheets can be done accurately, safely, and with minimal material waste.

Sustainability Spotlight: Recycled HDPE Sheets

As industries continue to shift toward greener practices, recycled HDPE sheets have emerged as a sustainable alternative to virgin plastic. These sheets are produced from post-consumer or post-industrial HDPE waste, such as milk jugs, detergent bottles, and discarded piping.

Why Choose Recycled HDPE Sheets?

Environmental Benefits: Reduces landfill waste and conserves raw petroleum resources.

Cost Efficiency: Often more affordable than virgin HDPE without sacrificing performance.

Durability: Maintains many of the same qualities as non-recycled HDPE.

Các ứng dụng: Ideal for landscaping, industrial pallets, agricultural liners, and outdoor furniture.

Whether you're pursuing LEED certification or simply want to reduce your project’s environmental impact, recycled HDPE sheets are a smart and responsible choice.

Applications of HDPE Sheets Across Industries

The versatility of HDPE plastic sheets makes them a top material in countless applications:

Marine: Boat floors, dock fenders, and flotation components

Agriculture: Water troughs, liners, silo wall panels

Construction: Formwork, barrier boards, and underlayments

Industrial: Machine guards, conveyor liners, chemical tanks

Signage and Display: Weatherproof signs, billboards, and menu boards

Home & DIY: Cutting boards, toolboxes, wall panels

Whether indoors or outdoors, tấm nhựa HDPE offers the durability and adaptability required to meet various project demands.

Buying and Working With HDPE Plastic Sheets

When purchasing HDPE plastic sheets, here are a few important factors to consider:

Sheet Size and Thickness: Available from 1/16" to over 2" thick in full-size sheets or cut-to-size panels.

Color and Finish: Choose black for UV resistance, natural for FDA applications, or color-coded for aesthetic or organizational purposes.

Grade: FDA grade, marine grade, and recycled grade are available depending on usage.

Price: Cost varies based on thickness, material grade, and quantity. Recycled HDPE is generally less expensive than virgin material.

Also, if you’re planning to do your own cutting of HDPE sheets, make sure to choose the correct thickness and density for your tools and application.

HDPE Sheet FAQs

Q1: Can HDPE sheets be glued?

A: HDPE is resistant to most adhesives. For bonding, mechanical fasteners or specialized plastic welding is recommended.

Q2: Is cutting HDPE sheets difficult?

A: Not at all! With common woodworking tools and proper technique, cutting HDPE sheets is quick and easy.

Q3: Are HDPE plastic sheets safe for food use?

A: Yes, FDA-grade HDPE plastic sheets are non-toxic and safe for food contact.

Q4: Do recycled HDPE sheets perform as well as virgin HDPE?

A: Yes, for most structural and outdoor uses, recycled HDPE sheets provide comparable performance at a lower cost.

Q5: Where can I use HDPE sheets around the home?

A: They’re great for DIY furniture, outdoor storage, wall panels, and garage organizers due to their durability and weather resistance.

From industrial durability to eco-conscious design, the tấm nhựa HDPE is an all-purpose material that checks all the right boxes. Whether you're interested in cutting HDPE sheets for a custom project, using HDPE plastic sheets in construction, or embracing sustainability with recycled HDPE sheets, this material delivers exceptional value and versatility.

With unmatched strength, weather resistance, and adaptability, HDPE is more than just a plastic sheet—it’s a long-term solution for modern challenges in fabrication, design, and sustainable manufacturing.

-

Welding Rods: The Backbone of Plastic Welding Applications

Tin tứcJun.06,2025

-

PVC Sheet: A Versatile Material for Modern Construction and Design

Tin tứcJun.06,2025

-

PVC Rod: A Reliable and Versatile Material for Industrial Applications

Tin tứcJun.06,2025

-

Pipe Fittings: Essential Components for Secure and Efficient Plumbing Systems

Tin tứcJun.06,2025

-

HDPE Sheet: Durable, Versatile, and Eco-Friendly Plastic for All Applications

Tin tứcJun.06,2025

-

HDPE Pipe Solutions: Durable, Versatile, and Built to Last

Tin tứcJun.06,2025