Nov . 06, 2025 05:20 Back to list

PVC Clear Sheet – High Clarity, Durable, Cut-to-Size

PVC Clear Sheet is a key solution in the manufacturing industry, specifically within plastic product industry and Manufacturing of plastic boards, sheets, and films. This article explores how Baoding Lida Plastic Industry Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- PVC Clear Sheet Overview

- Benefits & Use Cases of PVC Clear Sheet in Manufacturing of plastic boards, sheets, and films

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on PVC Clear Sheet from Baoding Lida Plastic Industry Co., Ltd

PVC Clear Sheet Overview

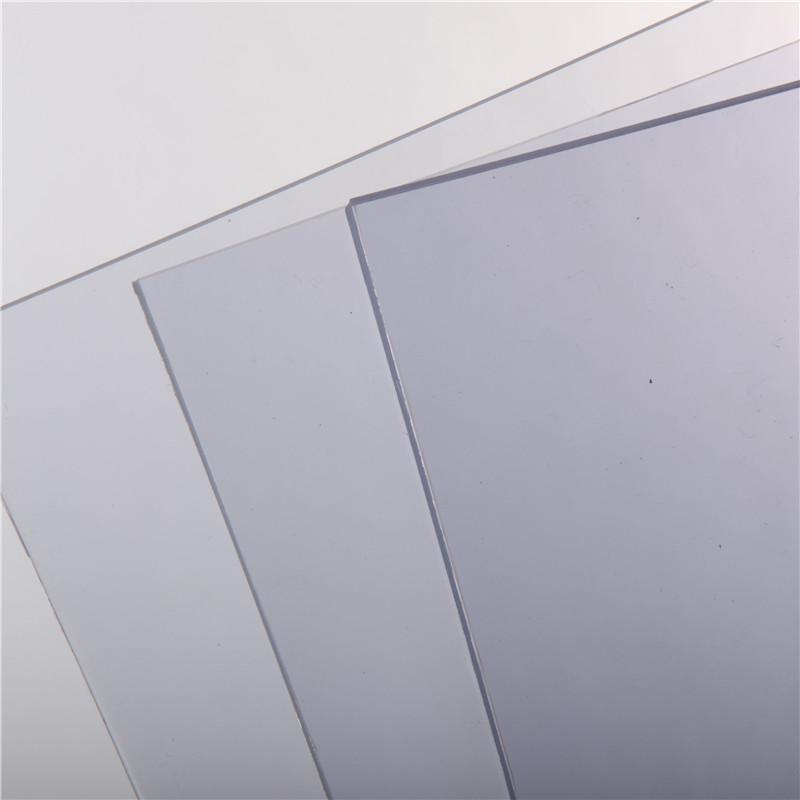

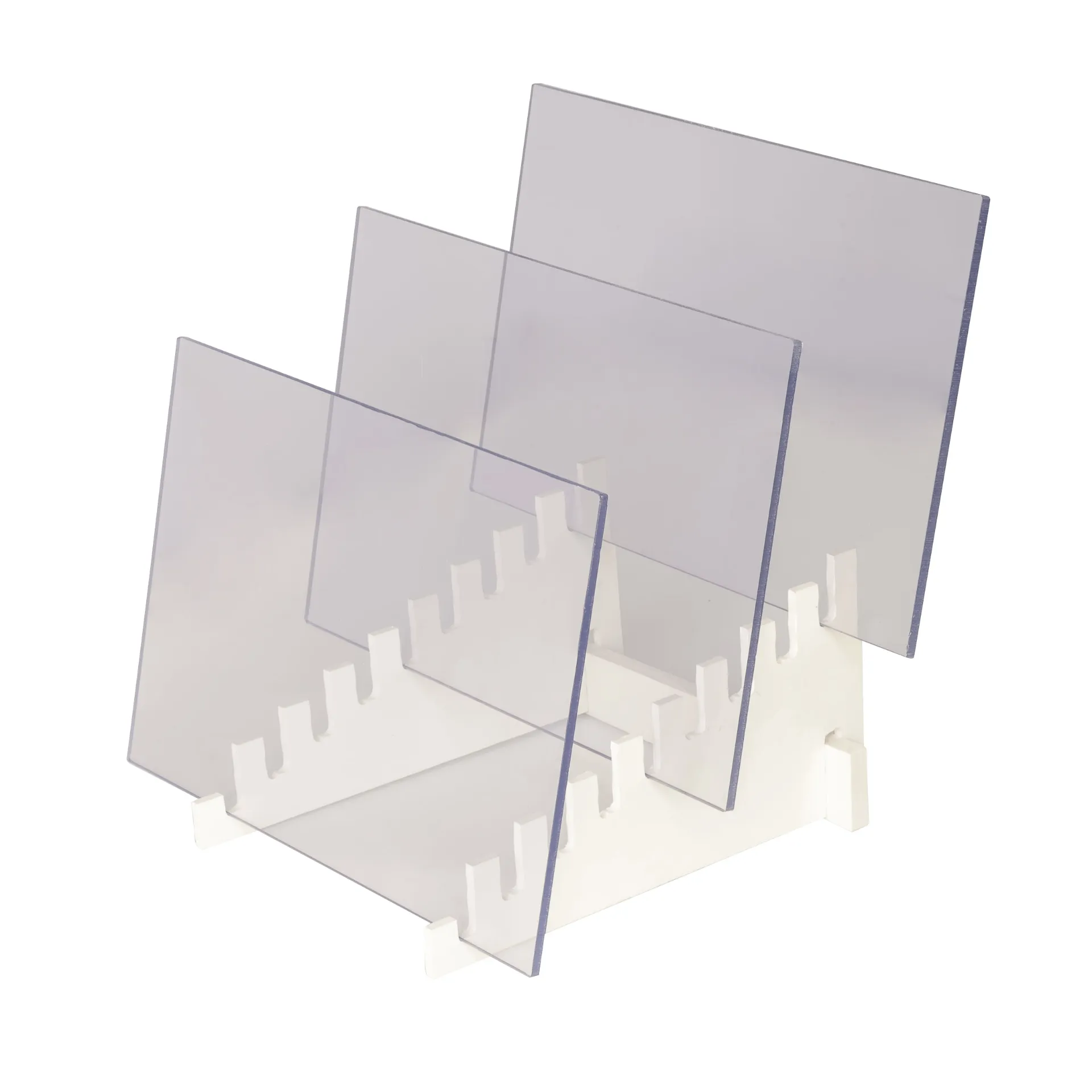

In B2B manufacturing environments, PVC Clear Sheet is prized for its balanced combination of optical clarity, rigidity, chemical resistance, and cost efficiency. Rigid polyvinyl chloride sheets deliver high light transmission while providing dimensional stability and ease of fabrication, making them a mainstay in the plastic product industry and across the Manufacturing of plastic boards, sheets, and films. Typical technical parameters include light transmittance around 85–90% (depending on thickness and formulation), tensile strength in the 45–60 MPa range, and a Vicat softening point commonly around 75–80°C—suitable for thermoforming, vacuum forming, cold bending, CNC routing, and die cutting. Common thickness options range from sub-millimeter gauges to several millimeters for protective panels and equipment guards.

- Relevance: Replaces acrylic in applications where better chemical resistance and self-extinguishing behavior are needed, yet a transparent aesthetic is essential.

- Specs and processing: Good printability (with proper surface treatment), compatible with standard adhesives and mechanical fastening; masks with PE film to protect surfaces in transit.

- Manufacturer you can trust: Baoding Lida Plastic Industry Co., Ltd combines stable extrusion processes and quality control to produce consistent PVC Clear Sheet tailored for converters, fabricators, and OEMs.

Benefits & Use Cases of PVC Clear Sheet in Manufacturing of plastic boards, sheets, and films

PVC Clear Sheet supports a wide spectrum of downstream manufacturing. In production lines, it is used for machine guards, sight windows, conveyor covers, and cleanroom partitions. In product fabrication, it becomes point-of-purchase displays, protective folders, signage substrates, and packaging windows. For builders and industrial OEMs, it serves as glazing for cabinets, instrument covers, and splash shields. The material’s self-extinguishing nature, robust chemical resistance versus acrylic, and ease of thermoforming at relatively lower temperatures than polycarbonate help shorten cycle times and reduce scrap. It also prints well for high-impact branding and can be ordered with glossy, matte, or embossed finishes to suit optical or anti-glare requirements.

- Applications: Machine safety panels, instrument covers, printing and display boards, box windows, folding boxes, and protective barriers.

- Competitive advantages: Reliable clarity, impact and chemical resistance, dimensional stability, and attractive cost-to-performance versus alternatives like acrylic and PETG in many use cases.

- Manufacturer expertise: Baoding Lida Plastic Industry Co., Ltd understands converter requirements—gauge consistency, surface cleanliness, protective masking, and packaging—so sheets arrive production-ready, minimizing line interruptions.

Cost, Maintenance & User Experience

Total cost of ownership with PVC Clear Sheet is attractive because of long service life, straightforward processing, and lower forming temperatures compared to some engineering plastics. For procurement teams, the ROI comes from reduced machining time, good print adhesion (with appropriate pre-treatment), and low rejection rates when gauge and optical clarity are consistent. Maintenance is minimal: clean with mild soap solutions and soft, non-abrasive cloths; avoid strong solvents that can stress-crack transparent plastics; and use appropriate PVC-compatible adhesives or mechanical fastening when assembling. Storage in a cool, dry environment—away from direct sunlight—preserves clarity and prevents warping.

- Durability and ROI: Strong chemical resistance helps extend lifespan in industrial environments, which reduces replacement frequency and downtime.

- User feedback: Fabricators value predictable sheet flatness and protective film masking that reduces handling marks, enabling faster throughput and cleaner finished parts.

Sustainability & Market Trends in manufacturing

Sustainability is redefining material selection across the plastic product industry. For PVC Clear Sheet, the shift toward heavy-metal-free stabilizer systems (such as Ca-Zn), increased transparency on material safety, and greater use of post-industrial recyclate where appropriate are key trends. Specifiers increasingly request documentation to align with regulations in key markets (e.g., REACH and RoHS compliance expectations for restricted substances) and to support corporate environmental goals. Design for disassembly, take-back of clean scrap, and closed-loop recycling are growing focus areas for converters and OEMs.

- Market trajectory: Demand remains solid for safety glazing, retail fixtures, and packaging windows that combine clarity with robust performance and cost control.

- Forward-thinking partner: Baoding Lida Plastic Industry Co., Ltd stays aligned with evolving standards and supports customers with material options and documentation that help meet environmental and regulatory objectives.

Conclusion on PVC Clear Sheet from Baoding Lida Plastic Industry Co., Ltd

For manufacturers of plastic boards, sheets, and films, PVC Clear Sheet delivers a reliable combination of clarity, formability, and chemical resistance at an excellent cost-to-performance ratio. Whether you are producing machine guards, display substrates, or packaging windows, working with Baoding Lida Plastic Industry Co., Ltd means consistent quality, responsive service, and material options engineered for downstream efficiency. Ready to specify your next project? Contact us: email: lidaplastic@ldsy.cn — Visit our website: https://www.lidaplastic.com

-

Efficient HDPE Pipe Drip Irrigation Systems for Sustainable Farming

NewsNov.21,2025

-

HDPE Rain Pipe Solutions: Durable & Sustainable Rainwater Management

NewsNov.20,2025

-

HDPE Pipe for Drip Irrigation – Sustainable Water Solutions for Agriculture

NewsNov.20,2025

-

Durable and Efficient Sprinkler HDPE Pipe Solutions for Global Water Management

NewsNov.19,2025

-

Durable and Efficient HDPE Irrigation Pipe Fittings for Sustainable Water Management

NewsNov.19,2025

-

Efficient and Durable HDPE Pipe Sprinkler Systems for Modern Irrigation

NewsNov.18,2025