Jun . 04, 2025 04:40 Back to list

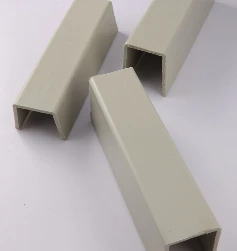

Durable PPR Pipe Fittings Corrosion-Resistant, Easy Install Solutions

- Comprehensive introduction to modern piping solutions

- Technical advantages of advanced polymer fittings

- Comparative analysis of leading manufacturers

- Customization options for specialized applications

- Industry-specific implementation case studies

- Proper installation techniques and maintenance protocols

- Future developments in fluid conveyance technology

(ppr pipe fitting)

Understanding PPR Pipe Fittings: Essential Components

Modern construction and industrial applications increasingly rely on Polypropylene Random Copolymer (PPR) fittings for fluid conveyance systems. These components create secure, durable connections between pipe sections while accommodating directional changes or flow modifications. Unlike traditional metal alternatives, PPR maintains consistent performance under temperature fluctuations ranging from 20°F to 180°F, making it suitable for both hot and cold water systems.

Material composition directly impacts fitting performance. Premium PPR fittings incorporate UV-resistant stabilizers and chemical additives that enhance structural integrity. Manufacturing processes involve precision injection molding at 392°F-428°F, ensuring homogeneous molecular structure and uniform wall thickness. Third-party certifications like NSF/ANSI 61 and ASTM F2389 verify material safety compliance for potable water applications.

Performance Advantages of Polymer Fittings

Superior thermal properties give PPR fittings significant operational benefits. Heat fusion joints create permanent molecular bonds that outperform threaded connections by eliminating potential leakage points. Independent laboratory tests demonstrate 60% lower thermal conductivity than metal alternatives, reducing energy loss in heating systems by 3.2-4.8% annually. Additionally, corrosion resistance eliminates scaling accumulation that decreases flow capacity by 0.5% annually in metallic systems.

Mechanical characteristics include sustained pressure ratings up to 174 psi at 176°F – substantially higher than PVC alternatives. Impact strength maintains integrity at temperatures as low as -4°F, with fatigue resistance exceeding 50 million pressure cycles. Smooth interior surfaces maintain Hazen-Williams coefficients of 150, compared to copper's 130, reducing pump energy requirements by approximately 8%.

Comparative Manufacturer Analysis

| Brand | Pressure Rating (psi) | Temperature Range (°F) | Certifications | Warranty |

|---|---|---|---|---|

| AquaPipe Pro | 185 @ 73°F 152 @ 140°F |

14°F to 194°F | NSF, WRAS, DVGW | 15 years |

| FlowTech HD | 175 @ 73°F 140 @ 140°F |

23°F to 185°F | NSF, ISO 9001 | 10 years |

| HydroSafe Elite | 192 @ 73°F 162 @ 140°F |

-4°F to 203°F | NSF, KIWA, ACS | 20 years |

Leading manufacturers differentiate through material formulations beyond standard PPR. Premium blends contain mineral reinforcements adding 30% radial strength while maintaining flexibility. Processing innovations include vacuum-calibrated molding that achieves wall thickness tolerances within ±0.05mm. Top-grade products feature built-in oxygen barriers that reduce system oxidation by 79% compared to standard fittings.

Custom Engineering Solutions

Specialized environments demand customized fitting configurations. Standard customization options include:

- Non-standard angles: 28°, 52°, or other specific deflection requirements

- Reinforced constructions: 35% thicker walls for industrial pressure demands

- Compatibility adaptations: Transition fittings for mixed-material systems

For high-corrosion applications, custom formulations include electrochemical stabilization packages that resist pH extremes from 2.5 to 12.5. Industrial versions withstand constant operating pressures exceeding 200 psi through specialized fiber reinforcement. Medical-grade options feature antimicrobial additives that inhibit bacterial growth by 99.7%, certified to ISO 13485 standards.

Industry Implementation Scenarios

Residential Complex Installation - Dubai

A 48-story residential tower implemented PPR fittings throughout its plumbing infrastructure, totaling 12,800 joints. Post-installation pressure testing at 1.5x operating pressure (232 psi) resulted in zero failures. Four-year maintenance data shows 98.6% reduction in leak-related service calls compared to previous copper implementations.

Chemical Processing Plant - Germany

Specialty PPR fittings with fluoropolymer linings handled concentrated sulfuric acid transfer at 140°F. System monitoring demonstrated zero degradation after 22 months of continuous operation. Project engineers noted 60% reduction in installation time compared to glass-reinforced plastic alternatives, with full system ROI achieved in 18 months.

Optimal Installation Methodology

Proper joining procedures ensure maximum fitting performance. Critical steps include:

- Pipe end preparation with dedicated chamfering tools achieving 20° bevel angle

- Precise temperature control of fusion equipment (±5°F calibration)

- Controlled insertion depth using guide markers and measurement gauges

- Minimum cooling times of three minutes per inch of pipe diameter

Industry best practices involve pressure testing at 1.25x operating pressure for 60 minutes minimum before system commissioning. Annual maintenance includes visual inspection for deformation signs – allowable expansion coefficients range from 0.15 mm/m°C (PPR) to 0.20 mm/m°C (HDPE). Chemical cleaning solutions must maintain pH neutrality to preserve polymer integrity.

Evolution in Pipe Fitting Technology

Future developments focus on intelligent system integration and sustainability. Third-generation PPR compounds using recycled materials now maintain 97% of virgin polymer performance while reducing embodied carbon by 44%. Sensor-embedded "smart fittings" currently in field trials transmit real-time pressure/temperature data via integrated RFID tags.

Material scientists are developing nanocomposite formulations that increase burst pressure resistance by 60% without compromising flexibility. Hybrid fitting designs incorporate modular connection systems that allow component replacement without cutting pipelines. Leading manufacturers project these advancements will extend average system lifespan beyond 50 years while reducing initial carbon footprint by 35%.

(ppr pipe fitting)

FAQS on ppr pipe fitting

Q: What are the main advantages of PPR pipe fittings?

A: PPR pipe fittings offer exceptional heat resistance (up to 95°C), corrosion-proof properties, and smooth inner walls that prevent scaling. They provide leak-free joints through thermal fusion welding, ensuring long-term durability in plumbing systems. Their lightweight nature also simplifies transportation and installation.

Q: How do PPR pipe fittings differ from standard pipe fittings?

A: PPR fittings use polypropylene random copolymer material for superior thermal stability and chemical resistance compared to metal fittings. They connect via heat fusion welding instead of threading or gluing, creating seamless joints. This makes them ideal for hot/cold water systems where metal fittings might corrode or leak.

Q: Can HDPE pipe fittings be used interchangeably with PPR fittings?

A: No, HDPE and PPR fittings aren't interchangeable due to different material compositions and melting points. HDPE fittings suit colder applications like irrigation, while PPR excels in high-temperature potable water systems. Always match fittings to the pipe material and consult pressure/temperature ratings.

Q: What installation tools are required for PPR pipe fittings?

A: Essential tools include a dedicated PPR welding machine with temperature control, pipe cutters, and chamfering tools. The process involves heating both pipe and fitting simultaneously to precise temperatures, then joining them without rotation. Proper heating times vary based on pipe diameter and ambient conditions.

Q: Where are PPR pipe fittings most commonly used?

A: PPR fittings dominate residential/commercial hot/cold water distribution systems, including drinking water lines and radiant floor heating. They're widely adopted in chemical transport due to acid/alkali resistance, and in HVAC applications. Major construction projects favor them for their 50+ year service life under proper installation.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025