جنوری . 29, 2025 02:10 Back to list

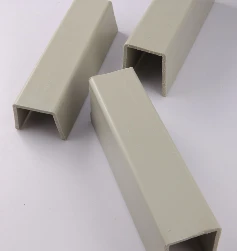

hdpe natural sheet

High-Density Polyethylene (HDPE) natural sheets have revolutionized numerous industries with their unmatched versatility, durability, and eco-friendliness. For those looking to incorporate this material into their production processes, understanding its potential and applications can bring significant advantages both financially and environmentally.

The expertise behind producing HDPE sheets involves a precise polymerization process that results in a polymer with tightly packed molecules. This gives HDPE its characteristic strength and durability. Manufacturers with advanced production capabilities can tailor these sheets to varying thicknesses, densities, and finishes to meet specific industrial requirements. Customization options ensure that targeted performance attributes are met, from UV protection for outdoor applications to enhanced fire retardant properties for specific safety standards. In terms of authority within the industry, HDPE’s reliability has been proven over decades of use. It is the material of choice for key infrastructure projects such as piping systems in urban and agricultural settings. Its extensive use in these fields is a testament to its capacity to perform under stress and environmental challenges without compromise. The credibility of HDPE sheet suppliers is crucial for businesses looking to integrate these products. Trustworthy suppliers offer not only a range of products but also provide vital technical support, helping customers optimize use and incorporate sheets effectively into their processes. This relationship ensures that businesses can leverage the full potential of HDPE natural sheets, maximizing efficiency and productivity. Ultimately, the use of HDPE natural sheets can be a game-changer for various industries. Their strength, sustainable profile, and adaptability make them an excellent choice for companies aiming for performance and environmental stewardship. As the global drive towards sustainability intensifies, materials like HDPE that offer durable solutions with minimal environmental impact will continue to gain prominence, supporting long-term industrial growth and eco-friendly innovations.

The expertise behind producing HDPE sheets involves a precise polymerization process that results in a polymer with tightly packed molecules. This gives HDPE its characteristic strength and durability. Manufacturers with advanced production capabilities can tailor these sheets to varying thicknesses, densities, and finishes to meet specific industrial requirements. Customization options ensure that targeted performance attributes are met, from UV protection for outdoor applications to enhanced fire retardant properties for specific safety standards. In terms of authority within the industry, HDPE’s reliability has been proven over decades of use. It is the material of choice for key infrastructure projects such as piping systems in urban and agricultural settings. Its extensive use in these fields is a testament to its capacity to perform under stress and environmental challenges without compromise. The credibility of HDPE sheet suppliers is crucial for businesses looking to integrate these products. Trustworthy suppliers offer not only a range of products but also provide vital technical support, helping customers optimize use and incorporate sheets effectively into their processes. This relationship ensures that businesses can leverage the full potential of HDPE natural sheets, maximizing efficiency and productivity. Ultimately, the use of HDPE natural sheets can be a game-changer for various industries. Their strength, sustainable profile, and adaptability make them an excellent choice for companies aiming for performance and environmental stewardship. As the global drive towards sustainability intensifies, materials like HDPE that offer durable solutions with minimal environmental impact will continue to gain prominence, supporting long-term industrial growth and eco-friendly innovations.

Share:

Next:

Latest news

-

Premium Glossy PP Rigid Sheet – Durable & Versatile

NewsAug.07,2025

-

High-Quality HDPE Sheet | Durable Plastic Panels

NewsAug.06,2025

-

High-Precision PVC Rigid Sheets for Vacuum Forming | AI-Optimized

NewsAug.05,2025

-

Durable PVC-M Water Supply Pipes | 60-Year Life

NewsAug.04,2025

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025