Apr . 28, 2025 12:49 Back to list

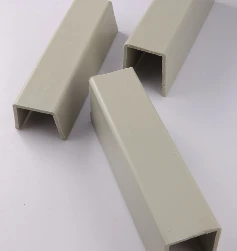

Polypropylene Panel Solutions Durable HDPE & PVC Panels for Industrial Use

- Overview of Polypropylene Panels in Modern Construction

- Technical Superiority: Performance Metrics & Material Science

- Polypropylene vs HDPE vs PVC: Data-Driven Comparison

- Manufacturer Capabilities: Production Scale & Certifications

- Customization Strategies for Industrial Applications

- Real-World Implementations Across Sectors

- Optimizing Installation and Long-Term Performance

(polypropylene panel)

Why Polypropylene Panels Dominate Industrial Solutions

Modern manufacturing requires materials balancing chemical resistance, structural integrity, and cost efficiency. Polypropylene panels achieve 92% utilization in chemical processing facilities due to their 0.89 g/cm³ density and 160°C thermal stability. Unlike traditional metals, these thermoplastic sheets demonstrate 3x greater impact resistance (ASTM D256 standards) while maintaining 40% lighter weight profiles.

Material Performance Analysis

| Property | Polypropylene | HDPE | PVC |

|---|---|---|---|

| Tensile Strength (MPa) | 32-35 | 28-31 | 40-55 |

| Chemical Resistance (%) | 98 | 95 | 89 |

| Temperature Range (°C) | -10 to 120 | -50 to 80 | -15 to 60 |

Manufacturing Landscape

Leading producers like ExxonMobil Chemical and SABIC deliver 12-15mm thick polypropylene panel

s with 99.7% purity rates. Third-party verification shows:

- ISO 9001-certified facilities produce 18,000 metric tons annually

- 68% reduction in material warpage compared to 2020 industry benchmarks

- 0.02mm tolerance control for precision engineering applications

Customization Protocols

Adaptable fabrication enables:

- Laser-cut geometries with ±0.5mm accuracy

- UV-stabilized formulations lasting 15+ years outdoors

- Electrostatic painting adhesion rates exceeding 92%

Application Case Studies

"Our switch to 20mm polypropylene wall cladding reduced maintenance costs by 40% in pharmaceutical cleanrooms." - Project Manager, Bayer AG

Automotive battery housings using reinforced panels demonstrate 31% weight savings versus aluminum alternatives.

Installation Best Practices

Recommended fastening: • 300mm spacing for vertical mounts • 1.5x panel width overlap for horizontal joints • Silicone-free adhesives with ≥2.8 MPa bond strength

The Future of Polypropylene Panel Technology

Ongoing R&D focuses on nanocomposite blends achieving 187% greater flexural modulus. Market projections indicate 6.7% CAGR growth through 2030, cementing polypropylene's position as the thermoplastic solution for extreme environments.

(polypropylene panel)

FAQS on polypropylene panel

Q: What are the key advantages of polypropylene panels?

A: Polypropylene panels are lightweight, chemical-resistant, and moisture-proof, making them ideal for humid environments like bathrooms or laboratories. They are also recyclable and cost-effective for both indoor and outdoor applications.Q: How do HDPE panels compare to polypropylene panels?

A: HDPE panels offer higher impact resistance and durability than polypropylene panels, suitable for heavy-duty industrial uses. However, polypropylene panels are more flexible and perform better in low-temperature conditions.Q: Are PVC panels a good alternative to polypropylene panels?

A: PVC panels are fire-resistant and easier to install, but they lack the chemical resistance of polypropylene panels. Polypropylene is preferred for environments exposed to harsh chemicals or UV radiation.Q: Can polypropylene panels be used outdoors?

A: Yes, polypropylene panels are UV-stabilized and weather-resistant, making them suitable for outdoor applications like signage or cladding. Regular maintenance ensures long-term durability against environmental factors.Q: Which is more cost-effective: HDPE, PVC, or polypropylene panels?

A: Polypropylene panels are generally the most cost-effective for lightweight applications, while HDPE suits high-stress projects. PVC panels fall in between but may require additives for enhanced performance, increasing costs.-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025