- Product introduction

- PP rigid sheet UV stabilized composition is mainly polypropylene, color master, anti-ultraviolet stabilizer, after high temperature solution and coagulation and then produced. The UV stabilized sheet has excellent aging resistance performance, and can be used for outdoors.

- Type of PP sheet

- 1.Pure PP board

Small density, easy to weld and process, with excellent chemical resistance, heat resistance and impact resistance, non-toxic, tasteless is one of the most in line with the environmental protection requirements of engineering plastics.

2.Polypropylene (PP) extrusion sheet

PP resin adds a variety of functional additives by extrusion, pressure, cooling, cutting and other processes made of plastic sheet.

3.Glass fiber reinforced PP sheet

After 20% is reinforced by glass fiber, in addition to maintaining the original excellent performance, strength, rigidity, etc. are doubled compared with PP.

4.PPH board, (β)-PPH single-sided non-woven sheet

The product has excellent resistance to oxygen aging, long service life and good mechanical properties. - Characteristics

- Very good welding and processing properties;

Excellent impact strength;

Excellent chemical and corrosion resistance;

Excellent formability;

Good abrasion resistance and electrical properties;

Light weight, non-toxic;

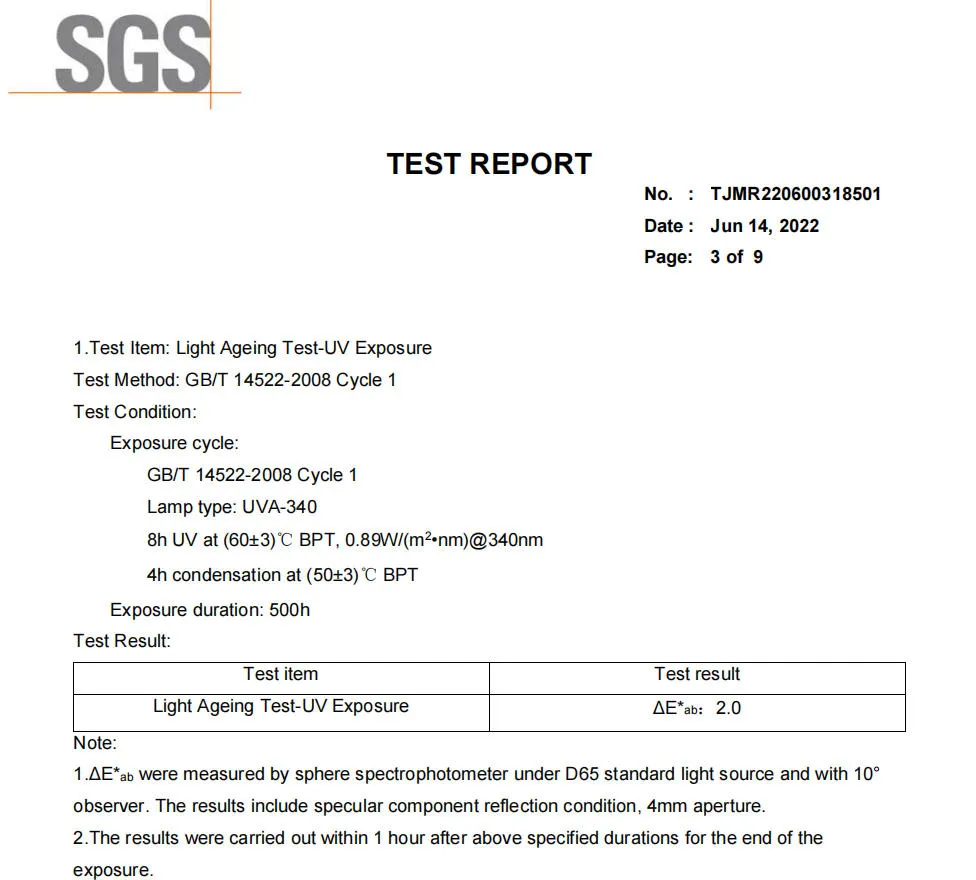

Excellent aging resistance performance;

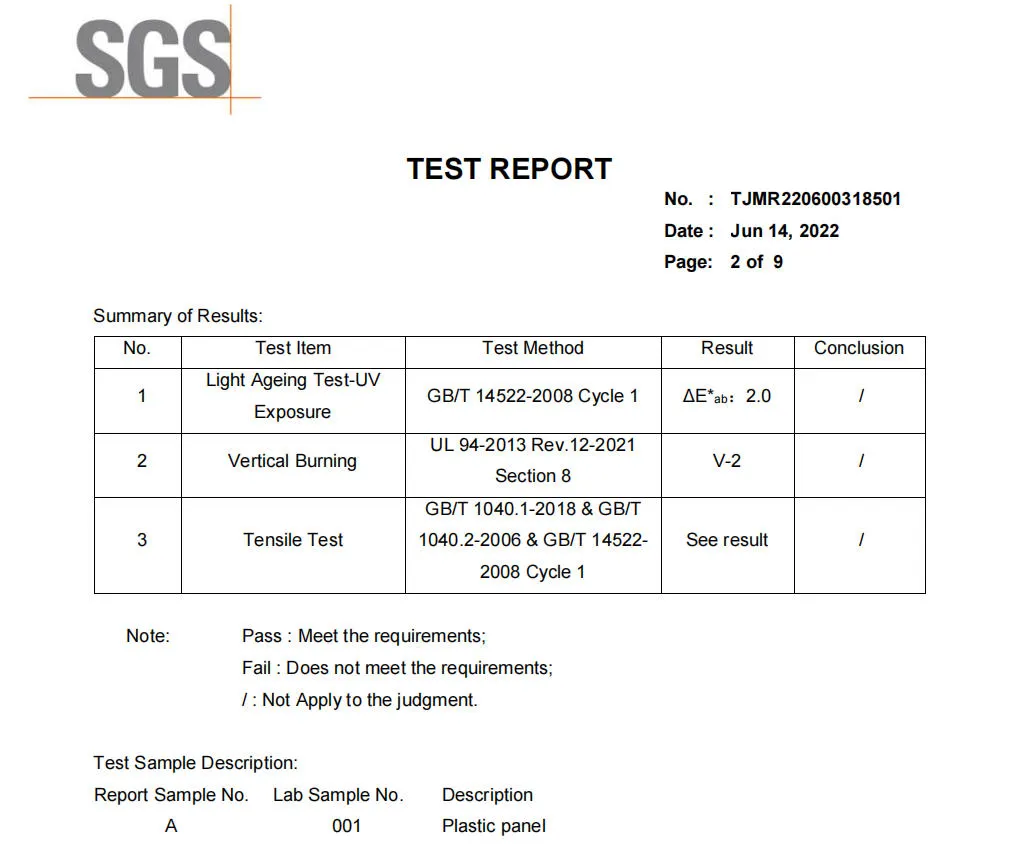

Excellent UV resistance property; - Execution standard

- This product is the main export product of our company, the products are exported to

the United Kingdom, Spain, Australia, Singapore, South Korea and other more than

ten countries. The product can meet the EU RoHS directive requirements. - Applications

- PP UV stablized sheet with special UV resistance property and the high impact strength, superior strength and it’s lower susceptibility to tension cracks are widely used for outdoors, chemical, mechanical and electronic industries, e.g. tanks, Lab equipments, Etching equipments, Semiconductor processing equipments, Plating Barrels, machined parts, industrial doors, swimming pools and so on.

Write your message here and send it to us