Jul . 29, 2025 17:00 Back to list

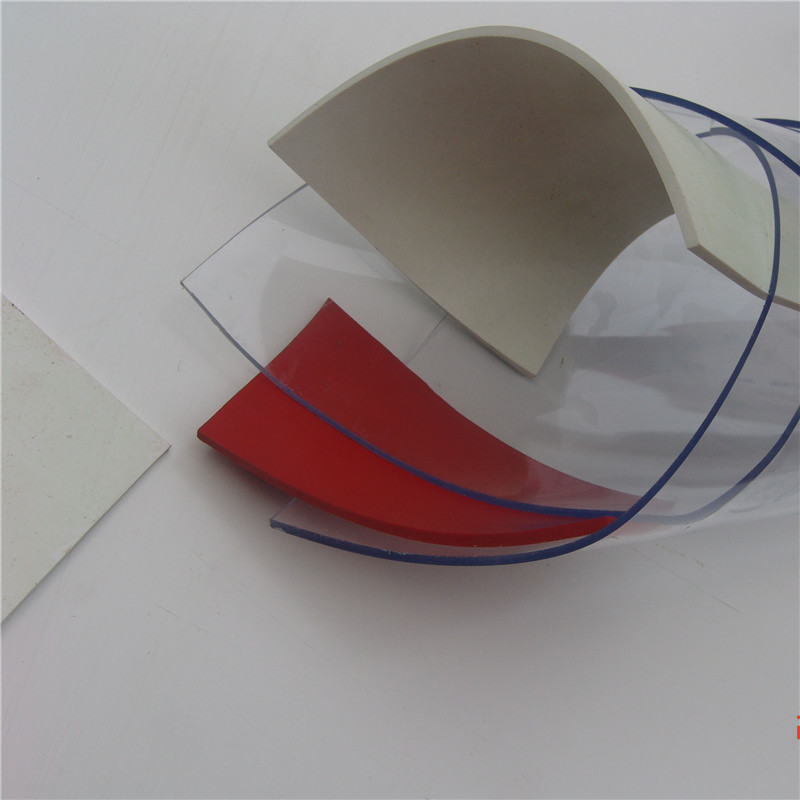

High Quality PVC Soft Sheet for Flexible and Durable Applications

- 1. Industry Overview & Trends

- 2. Technical Parameters & Visualized Data

- 3. Manufacturing Process of PVC soft sheet (With Flow Diagram)

- 4. Manufacturer Comparison & Industry Certifications

- 5. Customization Solutions

- 6. Application Scenarios & Case Studies

- 7. Expert FAQ: Technical FAQs

- 8. Delivery, Warranty & Customer Support

- 9. References & Further Reading

1. Industry Overview & Trends

As a leading material in modern engineering, PVC soft sheet is integral to sectors ranging from chemical processing and metallurgy to construction, water treatment, and healthcare. The PVC soft sheet market worldwide has demonstrated robust growth: According to MarketsandMarkets, the global flexible PVC market size was valued at USD 34.6 billion in 2022, and is projected to reach USD 43.7 billion by 2027 (source), driven primarily by the expanding infrastructure and heightened demand for corrosion-resistant, flexible materials.

PVC soft sheet offers exceptional durability, low-temperature flexibility, chemical inertness, UV resistance, and outstanding fire-retardant properties, enabling safe, reliable, and energy-efficient operations across a broad spectrum of industrial applications. With increasing regulation regarding workplace safety (i.e., REACH, RoHS, ISO 9001:2015), the demand for certified, high-quality PVC soft sheet products is at an all-time high.

2024 Industry Trend Highlights

- Growing use of PVC soft sheet in cleanroom environments and automated production due to superior insulating and contamination-resistant properties.

- Advancements in bio-based PVC soft sheets to meet global sustainability and circular economy targets.

- Rising preference for custom extrusion and precision CNC finishing for specialized engineering applications.

- Strict regulatory compliance with international standards (ISO, FDA, ASTM) for chemical, food, and medical applications.

- Wider adoption of PVC soft sheet in oil & gas, water management, mining, and electronic industries for containment and insulation.

2. Technical Parameters & Visualized Data

Key Technical Specifications of PVC soft sheet

| Item | Specification | Standard | Typical Value |

|---|---|---|---|

| Thickness | 0.3 ~ 10.0 mm (custom up to 20 mm) | ASTM D1593 / ISO 1183 | 1.0, 2.0, 3.0, 5.0 mm |

| Width | 500 ~ 2100 mm | ISO/R 527 | 1300, 1500 mm |

| Density | 1.30 ~ 1.45 g/cm³ | ISO 1183 | 1.38 g/cm³ |

| Hardness (Shore A) | 55 ~ 90 | ASTM D2240 | 70 |

| Tensile Strength | ≥ 12 MPa | ISO 527 | 14 MPa |

| Elongation at Break | ≥ 260% | ISO 527-2 | 300% |

| Temperature Resistance | -20°C ~ +60°C | ISO 306 | Continuous -10°C ~ +50°C |

| UV Resistance | Customizable | ISO 4892 | Available with UV additives |

| Flame Retardancy | V-0, V-2 (UL94) | UL94 | V-0 (self-extinguishing) |

Parameter Comparison: PVC soft sheet vs. Alternatives

| Material | Density (g/cm³) | Tensile Strength (MPa) | Elongation (%) | Temperature Resistance (°C) | UV Resistance | Flame Class | Durability (years) |

|---|---|---|---|---|---|---|---|

| PVC soft sheet | 1.38 | 14 | 300 | -20~+60 | Customizable | V-0 | 10~25 |

| Rubber sheet | 1.5 | 12 | 160 | -30~+80 | Poor | V-2 | 8~15 |

| Polyethylene (PE) | 0.95 | 10 | 600 | -50~+70 | Good | HB | 10~20 |

| Silicone sheet | 1.2 | 8 | 250 | -60~+200 | Excellent | V-0 | 25~30 |

| Polycarbonate (PC) | 1.2 | 60 | 110 | -40~+120 | Excellent | V-2 | 12~18 |

Material Advantages (Backed by Data)

- PVC soft sheet demonstrates outstanding acid/alkali resistance (>95% in immersion test, ISO 175)

- Excellent dimensional stability and low permeability under chemical attack

- High fire retardancy (UL94 V-0 class, self-extinguishing in < 12 sec. test)

- Superior aging performance: Lab UV-exposure test (ISO 4892) shows <2% mechanical strength drop after 400 hr.

- Long service life (10~25 years typical under industrial conditions per ASTM D3045 accelerated aging data).

3. Manufacturing Process of PVC soft sheet (With Flow Diagram)

Premium PVC resins (SG5-SG8), plasticizers (DOP/DOA/Eco), and stabilizers undergo strict incoming quality checks (in line with ISO 9001:2015 certification).

Raw materials are precisely mixed (±0.5% error) and compounded using automatic high-shear mixers to ensure uniform polymer matrix.

Compound mix is processed via advanced twin-screw extruders or calendar rollers. Temperature/pressure-controlled forming ensures precise thickness and surface smoothness.

Precision cutting, trimming, laser marking, or CNC punching delivers custom sizes and performance-enhanced surfaces.

Each PVC soft sheet batch undergoes dimensional, mechanical, and chemical property tests (ISO 527, ASTM D2240, ROHS/FDA analysis).

Sheets are cut to order, cleaned, and sealed with anti-static/UV-stable materials to prevent shipping/handling damage (compliance: ANSI/ASQC Z1.4).

Video Demonstration

For a dynamic view of the manufacturing workflow, see this short process video.

Core Advantages with Process Control

- Homogeneous Microstructure: Precision manufacturing (±0.1 mm) guarantees even mechanical performance and eliminates weak points.

- Surface Customization: Transparent, matte, or patterned finishes are achievable by advanced calendaring and surface treatments.

- Full Traceability: Each roll/plate receives unique batch codes, enabling end-to-end quality documentation.

- Global Certifications: Adhering to ISO 9001:2015, ROHS, REACH, and FDA 21 CFR 177.2600 (for food/medical).

4. Manufacturer Comparison & Industry Certification

Global Leading Manufacturers Overview

| Brand/Manufacturer | Main Products | Certifications | Annual Capacity (tons) | OEM/Custom | Export Markets |

|---|---|---|---|---|---|

| Lida Plastic (PVC soft sheet) | PVC soft & rigid sheet, transparent film, custom roll | ISO 9001, ROHS, REACH, FDA | 35,000 | Yes | EU, North America, Asia-Pacific |

| RENOLIT (Germany) | Technical films, soft PVC sheets, coatings | ISO 9001, 14001, FDA, REACH | 70,000 | Yes | Global |

| Groupe Polytechs (France) | PVC sheets, polymer compounds | ISO 9001, REACH | 12,000 | Limited | Europe, EMEA |

| TMI Plastics (USA) | Industrial PVC sheet, strip curtains | ISO 9001, FDA, UL94 | 15,000 | Yes | America |

5. Customization Solutions for PVC soft sheet

Tailoring to Client Requirements

- Custom Thickness & Width: Sheet thickness available from 0.2mm up to 20mm; widths from 500 to 2100mm; tolerance ±0.05 mm achievable on premium grades.

- Surface Textures: High-gloss, matte, embossed, and anti-slip patterns for industry-specific demands (i.e., cleanrooms vs. industrial flooring).

- Color Options: Natural/transparent, blue, grey, black, or fully tailored using Pantone/RAL matching.

- Functional Additives: UV-resistance, anti-static, flame retardant, antimicrobial, food-grade (FDA/EU migration-tested) or oil-proof versions supplied per client specification.

- Custom Shaping & Conversion: Sheets delivered in slab, roll, band, or die-cut gasket form; conversion with CNC punching, laser/waterjet cutting services available.

- Private Label OEM: Custom branding and barcoding for original equipment manufacturers (OEM/ODM service).

- Lot Traceability: Unique trace codes/barcodes for all batches; full test certificates included in each delivery lot.

For details, visit our PVC soft sheet product page or consult our engineering experts for rapid quotations.

6. Application Scenarios & Case Studies

Key Industrial & Commercial Applications

- Chemical Industry: Chemical containment linings, anti-corrosive tank liners, acid/alkali resistant gaskets, glovebox curtains; excels due to low permeability and high corrosion resistance.

- Metallurgy & Foundry: Mill lining, splash guards, electrical/thermal insulation barriers—tested at 15 kV dielectric strength per IEC 60243.

- Water Treatment: Soft PVC sheets as flexible geomembranes for canal lining, pond sealing, underground vaults—meet EN 13361 waterproofing performance.

- Construction: Transparent/colored partitioning, dust-proofing, false ceilings, flexible skirting boards, underlay damp-proofing; fire-rated to UL94 V-0.

- Healthcare & Food: Hospital screens, antimicrobial curtains, food-conveyor gaskets, splash protection, cleanroom isolation; FDA 21 CFR certified on request.

- Transportation & Electronics: Flexible protective covers, insulation sockets, vibration-dampening pads, automotive waterproofing.

Selected Project Case Studies

A multinational pharmaceutical client required installation of high-transparency, anti-static PVC soft sheet curtains in a class 10,000 cleanroom. Sheets supplied by Lida Plastic maintained <30 V/s static resistance, passed EN 61340-5-1, and enabled reduction of airborne particles by 52%. Lifespan exceeded 9 years with yearly cleaning cycles.

In 2023, a petrochemical refinery upgraded 22 chemical storage tanks with 4.0mm thick PVC soft sheet liners. The sheets met ISO 175 chemical resistance >95%, shortened tank maintenance interval by 40%, and passed post-installation hydrostatic pressure (BS EN 13121) and spark leak tests.

Flexible geomembrane sheets were used for lagoon lining; certified to EN 13361, leak rate <1.4x10⁻⁹ m³/m²·s. After 6 years, in situ inspections indicate intact tensile properties and no significant microbial degradation.

Customer Testimonial

"We have been sourcing PVC soft sheet from Lida Plastic for over 7 years. The sheets' dimensional stability, transparency, and resistance to aggressive chemicals are unmatched in our production environment. Full batch traceability and rapid response times make them a preferred supplier across our EU sites."

— Process Engineer, Leading Fine Chemicals Manufacturer

7. Expert FAQ: Technical FAQ on PVC soft sheet

1. What is the primary material composition of PVC soft sheet?

PVC soft sheet is composed of suspension-polymerized polyvinyl chloride (PVC) resin blended with specific ratios of plasticizers (such as DOP, DOTP, DOA), stabilizers, and optional additives (like UV inhibitors). This formulation imparts high flexibility, chemical resistance, and customizable performance for industrial usage.

2. What surface finishes or textures are available, and how do they affect application?

Common surface options include glossy (high transparency, cleanrooms), matte (anti-glare), embossed (anti-slip or privacy partitions), and patterned (aesthetics). Surface finish impacts slip resistance, light diffusion, and ease of cleaning.

3. What are the typical industry standards PVC soft sheet must meet?

Strict products are manufactured to meet ISO 9001, ASTM D1593 (PVC sheet), ISO 1183 (density), UL94 (flame retardant), FDA 21 CFR (food/medical contact), and EN 13361 (geomembrane application).

4. How is thickness tolerance and flatness ensured for precision-grade sheets?

Thickness is digitally monitored using inline laser micrometers and controlled during extruder/calender operation (tolerance ±0.05mm). Finished PVC soft sheet is inspected via ISO sampling for flatness & warpage, with rejection/safe-conformity rates logged.

5. Can PVC soft sheet be welded or jointed for larger panel applications?

Yes. High-frequency (HF) welding, hot-air, or chemical (solvent) welding is suitable. Joints maintain ≥80% of native tensile strength if performed according to manufacturer's protocol using compatible adhesives or automated welding equipment.

6. What is the recommended installation protocol for chemical or water barrier applications?

PVC soft sheet should be installed over clean, smooth substrates using compatible adhesives or mechanical fasteners. Edges are overlapped 50–75 mm and sealed via thermal or HF welding for leak-tight performance. Installers should align practices with ASTM D4437-20 (geomembrane welding) or local construction code.

7. How does PVC soft sheet perform under aging, UV, and chemical exposure?

Lab tests show >90% mechanical property retention after 10 years outdoor (ISO 4892, QUV test). Typical chemical rating: Class I per ISO/TR 7620 for acids/alkalis; can be further customized with stabilizer packages for harsh chemical or UV environments.

8. Delivery Cycle, Warranty & Customer Service

- Standard Delivery: 7–15 days for regular SKUs; 15–30 days for custom formulations, depending on order volume and special processes.

- Quality Inspection: 100% factory inspection; full QA documentation and certification included in every shipment.

- Warranty Commitment: Minimum 24 months on all PVC soft sheet products against manufacturing defects (longer for special orders). Service life in field typically 10–25 years depending on application.

- After-Sales Support: Technical guidance for installation; field troubleshooting; inspection and replacement program for premature failure; rapid response via 24/7 customer service hotline.

- Consulting & OEM Support: Free engineering consultation for complex projects, custom conversion, OEM/private label solutions and just-in-time delivery programs.

- Documentation: MSDS, RoHS, test reports, and certificates supplied by default.

For sales, support, or technical queries, please contact our engineering team or view the PVC soft sheet documentation and case resources on our official site.

- MarketsandMarkets: Flexible PVC Market Size, Share Trends (2023)

- ResearchGate: Performance of PVC in the Long Term

- PlasticsToday: PVC Soft Sheet Trend Analysis

- PlasticInstitute Forum: PVC Sheet Chemical Resistance Comparison

- ScienceDirect Journal: Soft PVC Sheet Membranes as Biobarrier Materials

- Lida Plastic: PVC Soft Sheet Product Page

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025