Фев . 10, 2025 10:32 Back to list

PVC clear sheet

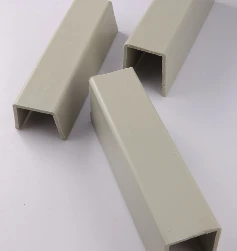

PVC pipes and fittings are vital components in modern construction and plumbing systems, known for their durability, versatility, and cost-effectiveness. In the wake of advancing construction technologies and environmental consciousness, PVC (polyvinyl chloride) has stood the test of time by evolving in design and application to meet diverse project demands.

Trustworthiness of PVC pipes and fittings is reinforced by the transparency in their manufacturing process and the traceability of materials. Top industry manufacturers provide detailed certification and testing results for their PVC products, which include assessments on pressure ratings, temperature thresholds, and chemical resistances. This transparency builds confidence, as clients and users can easily verify that the products they are investing in meet specific project requirements and environmental considerations. The sustainability impact of PVC pipes and fittings is another area where they excel. As a material that is lightweight, requires fewer resources to produce and transport, and can be recycled into new products, PVC represents a responsible choice for reducing the environmental footprint of construction projects. This aligns with the growing global demand for eco-friendly building practices and materials. Ultimately, the combination of these factors—durability, versatility, compliance with authoritative standards, transparency, and environmental sustainability—cements PVC pipes and fittings as a superior choice for construction professionals and DIY enthusiasts alike. The balance of cost-effectiveness and robust performance continues to solidify their standing in an ever-evolving market, proving they are more than just components; they are the backbone of innovative building solutions.

Trustworthiness of PVC pipes and fittings is reinforced by the transparency in their manufacturing process and the traceability of materials. Top industry manufacturers provide detailed certification and testing results for their PVC products, which include assessments on pressure ratings, temperature thresholds, and chemical resistances. This transparency builds confidence, as clients and users can easily verify that the products they are investing in meet specific project requirements and environmental considerations. The sustainability impact of PVC pipes and fittings is another area where they excel. As a material that is lightweight, requires fewer resources to produce and transport, and can be recycled into new products, PVC represents a responsible choice for reducing the environmental footprint of construction projects. This aligns with the growing global demand for eco-friendly building practices and materials. Ultimately, the combination of these factors—durability, versatility, compliance with authoritative standards, transparency, and environmental sustainability—cements PVC pipes and fittings as a superior choice for construction professionals and DIY enthusiasts alike. The balance of cost-effectiveness and robust performance continues to solidify their standing in an ever-evolving market, proving they are more than just components; they are the backbone of innovative building solutions.

Share:

Latest news

-

Durable PP Rigid Sheet: Versatile & High-Quality Plastic Panels

NewsAug.08,2025

-

Premium Glossy PP Rigid Sheet – Durable & Versatile

NewsAug.07,2025

-

High-Quality HDPE Sheet | Durable Plastic Panels

NewsAug.06,2025

-

High-Precision PVC Rigid Sheets for Vacuum Forming | AI-Optimized

NewsAug.05,2025

-

Durable PVC-M Water Supply Pipes | 60-Year Life

NewsAug.04,2025

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025