Nov . 13, 2025 06:00 Back to list

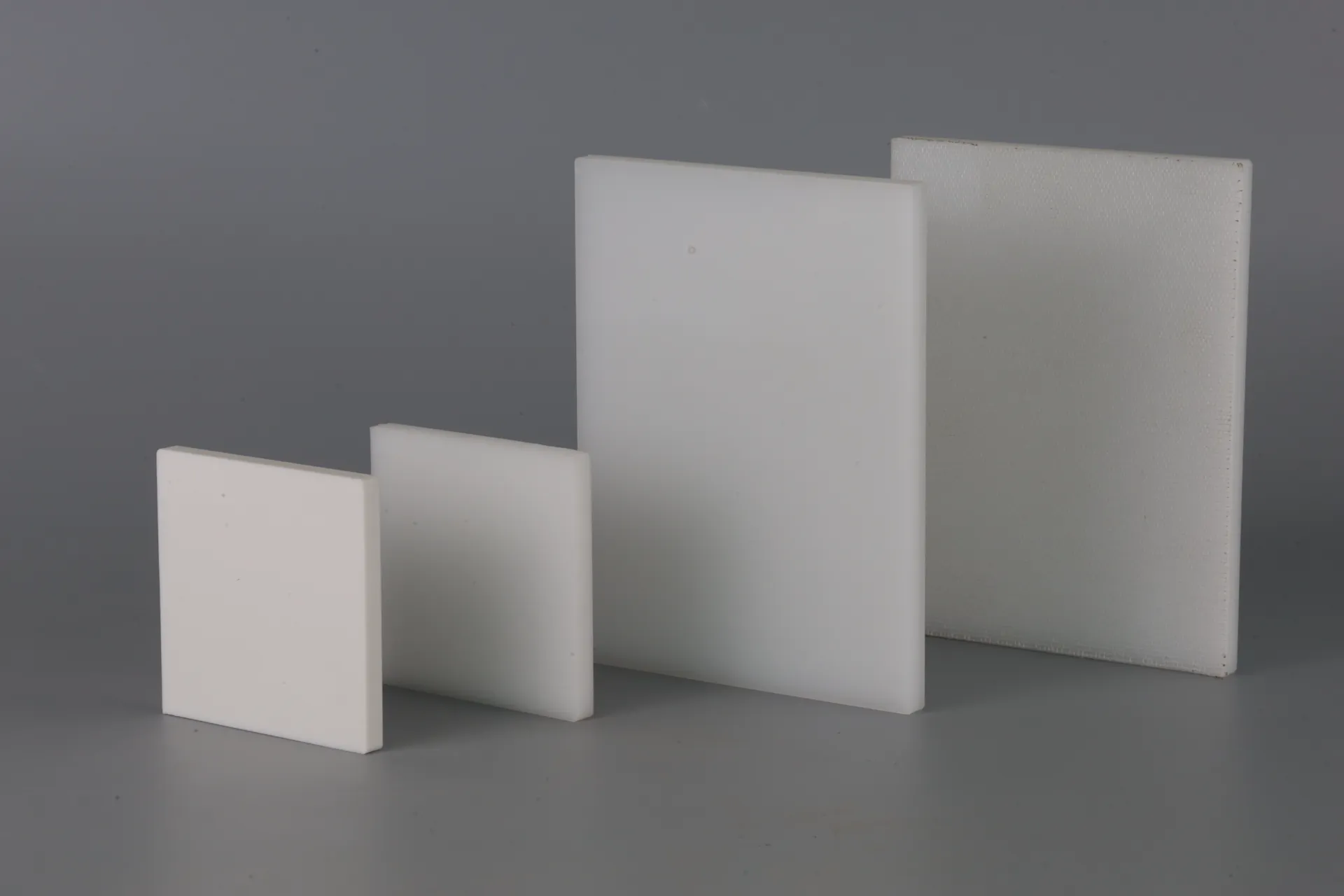

HDPE Natural Sheet – Virgin, Food-Grade, Cut-to-Size

HDPE Natural Sheet is a key solution in the chemical industry industry, specifically within Manufacturing of plastics and synthetic resins and Manufacturing of plastic sheets, pipes, and profiles. This article explores how Baoding Lida Plastic Industry Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- HDPE Natural Sheet Overview

- Benefits & Use Cases of HDPE Natural Sheet in Manufacturing of plastic sheets, pipes, and profiles

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in chemical industry

- Conclusion on HDPE Natural Sheet from Baoding Lida Plastic Industry Co., Ltd

HDPE Natural Sheet Overview

HDPE natural sheet is an unpigmented, high-density polyethylene sheet engineered for demanding environments where chemical resilience, impact strength, and process cleanliness are non-negotiable. In the chemical industry and across the manufacturing of plastics and synthetic resins—especially in sheet, pipe, and profile production—this substrate is widely used for fabrication, machining, linings, and tooling. Its balance of stiffness and toughness, paired with outstanding chemical resistance, makes HDPE Natural Sheet a practical, workhorse material on the factory floor.

- Typical technical profile: density ~0.95 g/cm³, very low moisture absorption, excellent impact resistance, and good abrasion resistance. Working temperature commonly ranges from -50°C to ~80°C, with a smooth, low-friction surface that machines cleanly and welds reliably.

- Available in a wide span of gauges and formats (e.g., from thin panels to thick slabs), HDPE natural sheet can be cut-to-size, CNC machined, thermoformed, and butt-welded, enabling efficient downstream processing for jigs, wear strips, guards, tanks, and trays.

- Baoding Lida Plastic Industry Co., Ltd manufactures consistent, high-quality sheets with tight thickness control and stable flatness to support precision fabrication. Custom options—such as textured surfaces, UV-stabilized, or antistatic grades—can be specified based on project requirements.

Benefits & Use Cases of HDPE Natural Sheet in Manufacturing of plastic sheets, pipes, and profiles

In sheet, pipe, and profile plants, HDPE natural sheet proves its value from production to packaging. Fabricators rely on it for chute linings, hoppers, guides, and star wheels because the low-friction surface minimizes sticking and abrasion. Extrusion teams use it for wear plates, calibration bed components, and haul-off pads to protect both equipment and product. It is also a dependable choice for chemical-resistant tanks, splash guards, machine covers, and conveyor sidewalls in corrosive or washdown environments.

- Competitive advantages: excellent chemical resistance versus acids, bases, and many solvents; robust impact and abrasion performance; weldability and machinability; low water absorption for dimensional stability; and the “natural” (unpigmented) purity that supports cleanliness-sensitive processes.

- Process-friendly: sheets can be CNC-routed, drilled, countersunk, heat-formed, and butt-welded with consistent results. Options like UV-stabilized or antistatic versions expand the envelope for outdoor or dust-sensitive applications.

- With deep know-how in this sector, Baoding Lida Plastic Industry Co., Ltd helps B2B buyers match grade, thickness, and finish to application—shortening development cycles and improving first-pass yield on the shop floor.

Cost, Maintenance & User Experience

Total cost of ownership is where HDPE Natural Sheet shines. Its durability reduces replacement frequency, while its abrasion resistance and low coefficient of friction cut wear on mating parts—translating into fewer stoppages and less unplanned maintenance. Fabrication is straightforward, enabling shorter lead times, efficient nesting, and lower scrap rates. For many fixtures and linings, HDPE replaces metal to eliminate corrosion and reduce weight, easing installation and handling.

- Maintenance is simple: routine cleaning with mild detergents keeps surfaces performing; unlike porous materials, HDPE naturally resists moisture ingress and many chemicals. When components wear, they can often be re-machined or quickly replaced with cut-to-size spares.

- Feedback from plastics manufacturers indicates lower downtime on conveying and forming lines after switching wear points to HDPE, along with smoother product handling and reduced surface scuffing. Combined, these factors support a compelling ROI for B2B operations under pressure to improve OEE and reduce lifecycle costs.

Sustainability & Market Trends in chemical industry

As the chemical and plastics sectors accelerate toward circularity, HDPE’s recyclability (resin code #2) is a strategic advantage. Regulatory drivers, extended producer responsibility (EPR) frameworks, and customer mandates are elevating the importance of materials that can be reclaimed and reprocessed. Lightweighting versus metal also helps lower transport emissions and installation energy. Within this backdrop, HDPE Natural Sheet supports long service life, easy reclamation of offcuts, and potential use of recycled content where appropriate to application needs.

- Forward-looking manufacturers seek suppliers who invest in efficient extrusion, waste minimization, and documentation that helps meet global requirements. Materials can be specified to align with common regulatory expectations (e.g., REACH/RoHS applicability for certain use cases) and to support internal sustainability KPIs.

- Baoding Lida Plastic Industry Co., Ltd partners with B2B decision makers to balance performance, cost, and environmental considerations—offering stable quality, consistent dimensions, and options that help customers advance ESG objectives without compromising throughput or reliability.

Conclusion on HDPE Natural Sheet from Baoding Lida Plastic Industry Co., Ltd

For chemical industry operations and manufacturers of plastic sheets, pipes, and profiles, HDPE Natural Sheet offers a dependable combination of chemical resistance, durability, machinability, and clean processing. It enhances productivity on extrusion lines, simplifies fabrication, and reduces lifecycle costs for fixtures, linings, and protective components. Backed by Baoding Lida Plastic Industry Co., Ltd’s manufacturing expertise and responsive service, it’s a smart choice for B2B teams optimizing performance and TCO. Contact us: email: lidaplastic@ldsy.cn. Visit our website: https://www.lidaplastic.com

-

Efficient HDPE Pipe Drip Irrigation Systems for Sustainable Farming

NewsNov.21,2025

-

HDPE Rain Pipe Solutions: Durable & Sustainable Rainwater Management

NewsNov.20,2025

-

HDPE Pipe for Drip Irrigation – Sustainable Water Solutions for Agriculture

NewsNov.20,2025

-

Durable and Efficient Sprinkler HDPE Pipe Solutions for Global Water Management

NewsNov.19,2025

-

Durable and Efficient HDPE Irrigation Pipe Fittings for Sustainable Water Management

NewsNov.19,2025

-

Efficient and Durable HDPE Pipe Sprinkler Systems for Modern Irrigation

NewsNov.18,2025