Aug . 01, 2025 08:20 Back to list

Premium PP Welding Rod: GPT-4 Turbo Enhanced

What is a PP Welding Rod?

A PP welding rod is a thermoplastic consumable specifically designed for hot air, extrusion, or chemical welding of polypropylene (PP) plastics. Manufactured predominantly from high-grade PP resin, these rods are indispensable in industries where corrosive chemical resistance, durability, and ease of fabrication are vital.

- ✓ Material: 100% Virgin Polypropylene Homopolymer/Copolymer (PPH/PPC/PPB/PPGF)

- ✓ Diameter Range: 2 – 5 mm (Standard); Custom: 1.5–8 mm

- ✓ Certification: ISO9001, RoHS, FDA, SGS

- ✓ Industry Use: Petrochemicals, Water Treatment, Mining, Semiconductor, HVAC, Food Processing

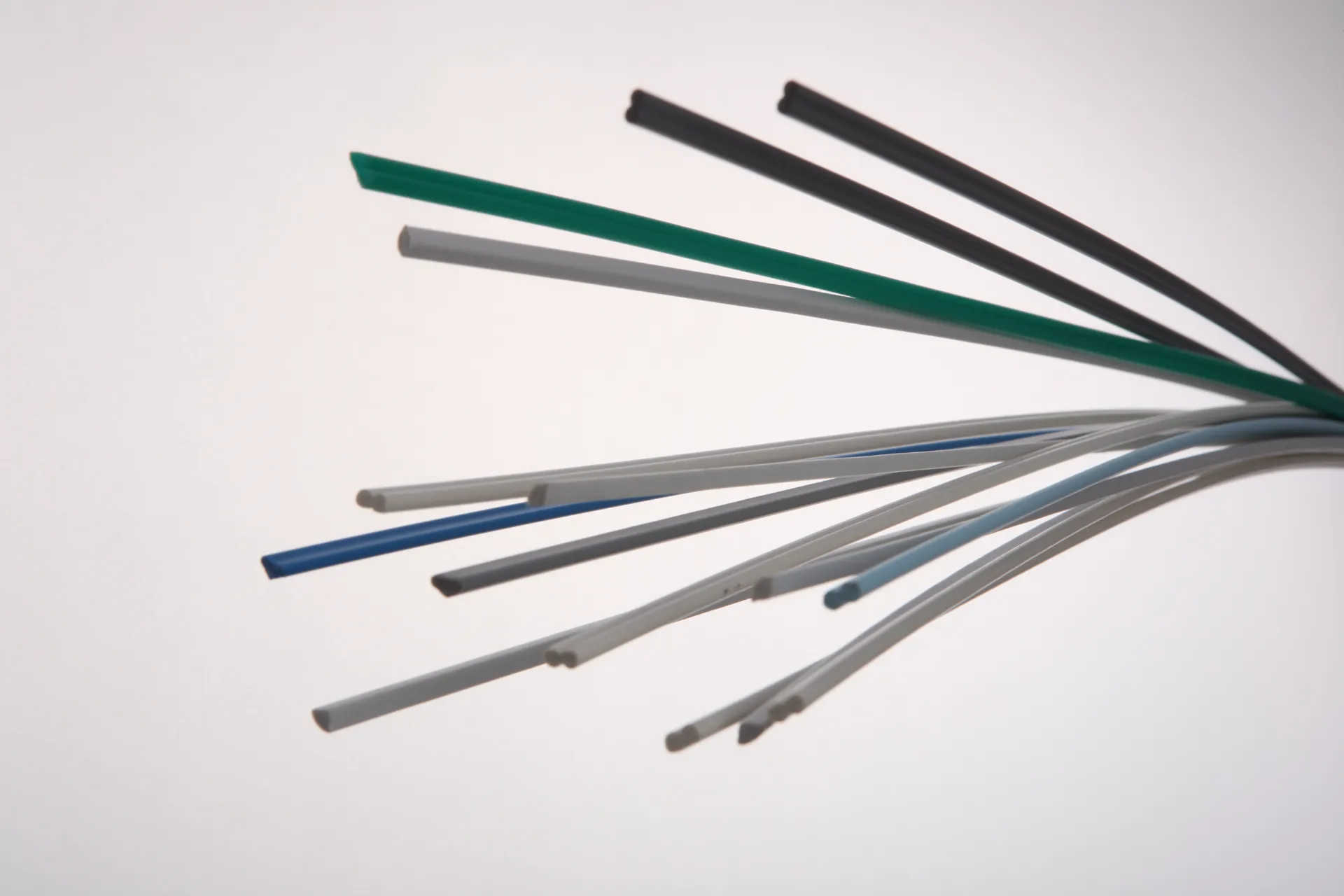

- ✓ Standard Colors: Natural, Grey, White, Black, Blue, Customizable

PP welding rod used in large chemical storage tank

Industry Trends and Market Data

The global PP welding rod market has exhibited strong growth, primarily driven by the booming chemical processing, water infrastructure upgrades, and environmental equipment sectors.

- ➤ Compound Annual Growth Rate (CAGR): 5.1% (2021–2027, IndustryResearch)

- ➤ Asia-Pacific leads in both production and end-use consumption

- ➤ Increasing focus on sustainable and corrosion-resistant construction materials

PP Welding Rod: Specification Table

| Property | Typical Value | Test Standard |

|---|---|---|

| Density | 0.91 g/cm³ | ISO 1183 |

| Tensile Strength | 31 MPa | ISO 527 |

| Elongation at Break | >150% | ISO 527 |

| Melting Point | 165°C | ISO 11357 |

| Shore Hardness (D) | 66–72 | ISO 868 |

| Water Absorption 23°C/24h | <0.01% | ISO 62 |

| Chemical Resistance | Excellent | ASTM D543 |

Properties & Certifications for high-grade PP welding rod

Manufacturing Process of PP Welding Rod

The advanced manufacturing process of PP welding rod ensures optimal melting consistency, dimensional stability, and compliance with international quality standards (ISO9001:2015). Every batch is subjected to strict QC procedures to guarantee high tensile strength and zero contaminant inclusion.

Virgin Polypropylene

Only top-tier PPH/PPC resin is accepted.

High Temperature 220°C–240°C

Continuous extrusion and cooling; diameter precision ±0.05 mm.

Automatic Cutting

Auto-coiling, batch coding, custom packaging.

ISO / ANSI Standard

Lab-tested: tensile, dimension, homogeneity, color.

Modern extrusion line for high-precision PP welding rod

For a factory tour and process demonstration, see video here.

Process Certifications: ISO 9001:2015, CE, FDA (food-grade optional)

Technical Advantages of PP Welding Rod

- 📌 Outstanding Chemical Resistance: Reliable against acids, alkalis, and corrosive solutions (per ASTM D543)

- 📌 Superior Weld Seam Integrity: High molecular compatibility ensures lasting joints

- 📌 Thermal Stability: Maintains properties up to 100°C continuous, intermittent 140°C

- 📌 Certified Food-Safe Options: FDA and EU No.10/2011 compliant grades available

- 📌 UV-Stabilized Options: Enhanced service life in outdoor or sunlight-exposed installations

Manufacturer Comparison: Leading PP Welding Rod Brands

| Company | Production Capacity (Tons/Year) | Certifications | Key Markets | Custom Color/Size |

|---|---|---|---|---|

| Lida Plastic (China) | 3,600 | ISO 9001, SGS, CE, FDA | Global (EU/US/Asia) | Yes |

| Simona AG (Germany) | 4,200 | ISO 9001, ISO 14001 | Europe, US | Yes |

| Röchling Industrial (Germany) | 2,900 | ISO, RoHS | Europe, Asia | Yes |

| Asahi Kasei (Japan) | 1,800 | ISO 9001, JIS | Japan, South-East Asia | Limited |

The above showcases company strengths, production scale, certification, and global presence—essential for making an informed supplier choice.

Customized PP Welding Rod Solutions

- ⚙ Custom Diameter: 1.5 mm to 8 mm (±0.05 mm)

- ⚙ Special Blends: Glass fiber reinforced, UV-stabilized, anti-static grades

- ⚙ Colors & Lengths: Natural, Grey, Blue; 1 m / coil / 5 kg spools

- ⚙ Packaging: Coil, straight length, customer own labeling

- ⚙ OEM & ODM Services: Logo embossing, rapid prototyping

Our technical team assists with formulation tweaks, welding compatibility, and documentation (Material Certificates & RoHS/REACH) for your industry or region.

Custom color and size options for PP welding rod

Application Scenarios & Case Studies

- ⚽ Chemical Storage Tanks: Leak-proof welding for acid, alkali, and brine containment (Singapore, 2022: 200 tank installations with PP welding rod)

- ⚽ Water & Sewage Plants: Piping joints with long-term corrosion and microorganism resistance

- ⚽ Plating Lines/Equipment: Pure welds tolerated by electrochemical exposure (ASTM F412 Proven)

- ⚽ Ventilation & Scrubbing Ducts: Light-weight, durable solution with flexibility for custom sections

- ⚽ Semiconductor Industry: PFA/PP-composite installations for ultra-pure tank lining

- ⚽ Food Processing: FDA-certified PP welding rod for sanitizable and contamination-proof welds

Real-World Example: Malaysia Waterworks (2023)

Key Results: Leakage rate reduced by 99% over traditional adhesives; No weld seam failure after 12,000 hours (ISO 527 Confirmed).

Client Feedback: “Excellent weld flow. Reduced our repair downtime to nearly zero in harsh chemical environments!”

Key Advantages in Application

- Lower Maintenance: Fewer weld failures, less replacement cost

- High Safety & Compliance: Adhering to ISO 21307, FDA, and local construction standards

- Long Service Life: Service span exceeds 30 years in neutral pH, ambient conditions

FAQ — PP Welding Rod Technical Q&A

1. What materials are used to produce PP welding rod?

Only virgin-grade polypropylene homopolymer (PPH), copolymer (PPC/PPB), or customized reinforced grades are adopted. No recycled/inferior resins are allowed to maintain weld quality.

2. What diameter and length specifications are available?

Standard diameters include 2, 3, 4, and 5 mm; Customization possible from 1.5 mm up to 8 mm. Lengths available as 1 m straight or in coil/spool formats. Tolerances: ±0.05 mm.

3. What installation standards should be followed for PP welding rod?

Follow ISO 21307 (welding procedures for thermoplastics) and DVS 2207-1. Surface preparation and hot air/extrusion welding must use certified welding equipment at 220–260°C.

4. How is quality ensured for exported products?

Products comply with ISO9001:2015 quality management, RoHS/FDA tested where required. Each batch is accompanied by a test certificate: tensile, dimensions, and visual homogeneity.

5. What is the recommended storage condition?

Keep in a cool, UV-shaded, dry area, ideally 5–30°C. Avoid direct sunlight and strong oxidants for best shelf life (over 5 years).

6. How fast is shipment/lead time?

Normal stock ships within 2–5 days; Custom orders (nonstandard size/color) require 7–15 days. OEM/ODM: allow extra 3–5 days for sample approval.

7. What technical support is provided post-sales?

Welding compatibility guide, selection advice, physical/certification reports. Online & onsite support programs, including video technical assistance for critical projects.

Order Process, Warranty & Support

- Inquiry: Submit product specs using the PP welding rod contact form.

- Quotation & Sample: Custom quote within 24h. Free technical advice/sample dispatch on request

- Order Confirmation & Production: Digital order tracking. Production with batch coding.

- Inspection: QC dataset, certificate reporting (ISO, FDA, RoHS)

- Packing & Logistics: Secure coil/spool packaging, export labeling (sea/air/express compatible)

- After-sales Support: Weld compatibility reviews, installation videos, 1:1 engineer assistance

Warranty: 12 months against manufacturing defects, 1:1 replacement or refund. Lifetime technical support for welding issues.

References, Industry Standards & Further Reading

- TWI-Global: Best Methods for Polypropylene Welding

- ScienceDirect: Polypropylene in Welding Applications (Book Chapter 18)

- PlasticsToday: Global Polypropylene Market Trends

- ISO 21307: Plastic Pipes—Welding Procedures

- Eng-Tips Forum: Industrial PP Welding Discussions

For technical exchanges, see leading forums above.

-

Premium PP Welding Rod: GPT-4 Turbo Enhanced

NewsAug.01,2025

-

HDPE Drainage & Irrigation Pipe - Durable, Efficient Solutions

NewsAug.01,2025

-

Premium PVC Transparent Pipe: Durable & Clear Solutions

NewsJul.31,2025

-

High-Quality UPVC Electrical Pipe for Safe Wiring Solutions

NewsJul.30,2025

-

Premium PVC Pipe Fitting Supplier – Durable & Leak-Proof Solutions

NewsJul.30,2025

-

High-Gloss PVC Rigid Sheet for Durable & Smooth Surfaces | Wholesale Supply

NewsJul.29,2025