Oct . 24, 2025 15:40 Back to list

PP rigid sheet(glossy surface) - clear, impact & chem-safe

A Field Guide to PP Rigid Sheet (Glossy): Trends, Specs, and Real-World Lessons

If you spend any time around fabrication shops or chemical plants, you’ll hear the same request: “Got glossy PP sheet in stock?” This is where [PP Rigid Sheet(glossy Surface)] earns its keep. It’s tougher than it looks, welds cleanly, and—surprisingly—holds a finish that wipes down easily in hygienic spaces. Origin story? Hebei, China (No.316 Pingan West Street, Shunping County, Baoding City, 072250). I’ve toured similar lines: steady extrusion, disciplined cooling, zero drama.

What’s driving demand right now

Two trends: chemical resistance for scrubbers/tanks and neat, low-porosity surfaces for food lines and lab fit-outs. Add the sustainability push—PP is recyclable—and you get a steady uptick. To be honest, the glossy finish also sells in signage and enclosure panels; it simply looks finished.

Technical snapshot

Base polymer: semi-crystalline polypropylene. LIDA blends PP homopolymer with ≈1–4% ethylene random copolymer for impact at low temps (because, yes, neat PP can be brittle above 0°C). Extruded, stress-relieved, glossy face. Many customers say the weld seam quality is consistently smooth—good for chemical tanks and ductwork.

| Spec | Typical Value (≈) | Standard |

|---|---|---|

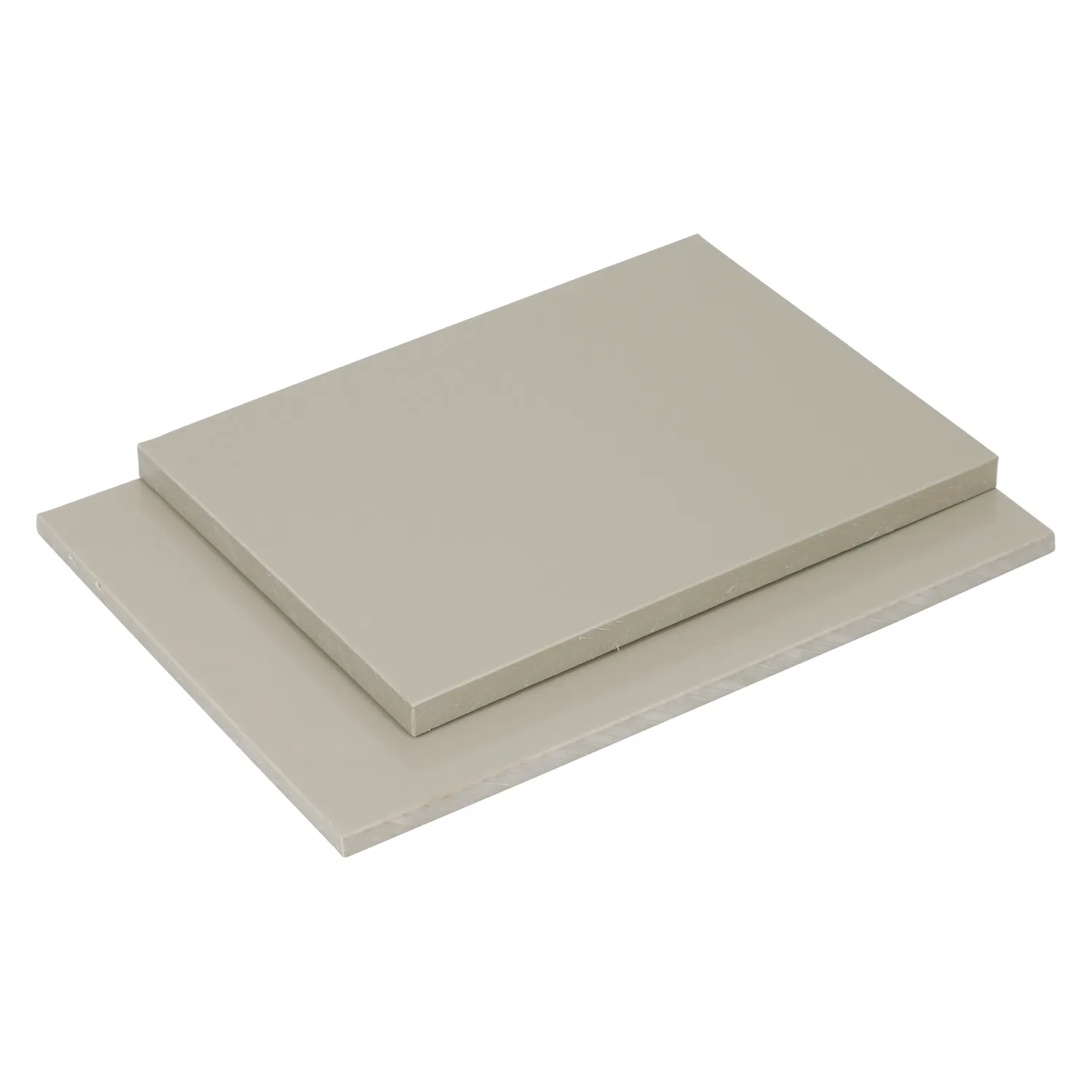

| Thickness | 2–40 mm (cut-to-size available) | Internal QC |

| Width | 2–20 mm: 1000–2400 mm; 25–40 mm: 1000–1500 mm | Internal QC |

| Length | Any length | — |

| Density | ≈0.90 g/cm³ | ISO 1183 |

| Tensile strength | ≈30–35 MPa | ISO 527 |

| Flexural modulus | ≈1.2–1.6 GPa | ISO 178 |

| HDT @0.46 MPa | ≈90–100°C | ASTM D648 |

| Melting point | ≈160–170°C | DSC |

| Gloss (60°) | >85 GU | ASTM D523 |

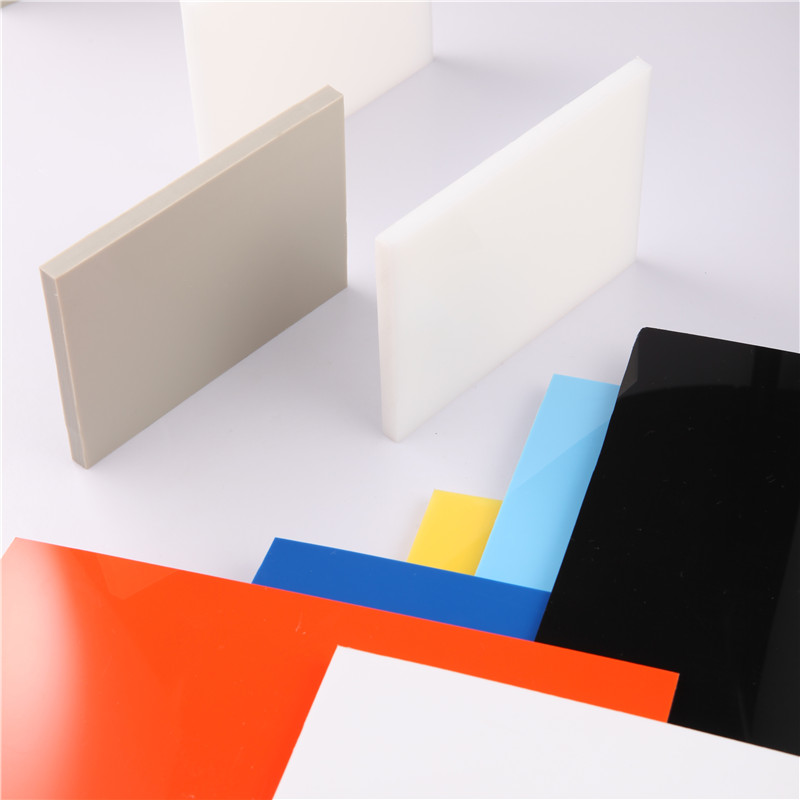

| Colors | Natural, grey (RAL7032), black, light blue, yellow, customs | — |

Process, testing, and service life

Process flow: resin selection → compounding (impact modifier, UV if specified) → twin-screw feed → flat-die extrusion → calibrated cooling → trimming → inspection → cut-to-size.

Testing: tensile (ISO 527), flexural (ISO 178), Vicat/softening (ISO 306), HDT (ASTM D648), impact (ASTM D256), and gloss uniformity. Certifications can include ISO 9001 QA; RoHS/REACH compliance is available on request. Real-world service life: indoors ≈10+ years; outdoors ≈3–5 years without UV package (longer with UV).

Where it’s used (and why)

- Chemical tanks, fume scrubber panels, ducting—resists acids/alkalis.

- Food plants and cleanrooms—glossy surface wipes down quickly.

- Machine guards, enclosures, trays—lightweight and stiff enough.

- Signage and liners—flatness plus that reflective finish.

Many fabricators say PP Rigid Sheet(glossy Surface) butt-welds predictably and machines without “gumming” when tools are sharp.

Vendor comparison (field-notes version)

| Vendor | Thickness tolerance | Colors | Lead time | Certs |

|---|---|---|---|---|

| LIDA Plastic | ≈±3% (≥5 mm) | Standard + custom RAL | 7–15 days | ISO 9001, RoHS/REACH |

| Vendor A | ≈±5% | Limited stock colors | 10–20 days | ISO 9001 |

| Vendor B | ≈±4% | Custom by MOQ | 15–25 days | RoHS |

I guess the difference often shows up in flatness and gloss uniformity—LIDA’s sheets tend to be less wavy on large panels.

Customization and ordering tips

- Cut-to-size service saves scrap and freight. Provide usable tolerances.

- Request UV-stabilized grade for outdoor exposure.

- Color-match to RAL; ask for a small plaque first.

- Specify weld rod compatibility with PP Rigid Sheet(glossy Surface).

Quick case notes

Plating shop retrofit: Replaced aging PVC lining with PP Rigid Sheet(glossy Surface); chemical mist staining dropped, and weekly cleanup time fell ≈30% (maintenance log, client report).

Snack processor: Light grey RAL7032 panels in washdown area; QA loved the gloss because residue is obvious—then gone.

Standards and references

Referenced methods: ISO 527, ISO 178, ISO 306, ISO 1183, ASTM D648, ASTM D256, ASTM D523. Compliance on request: ISO 9001, RoHS, REACH. Real-world results may vary with geometry, welds, and installation.

Authoritative citations

- ISO 527: Plastics — Determination of tensile properties. https://www.iso.org/standard/56046.html

- ASTM D648: Heat Deflection Temperature of Plastics. https://www.astm.org/d0648

- ISO 178: Plastics — Determination of flexural properties. https://www.iso.org/standard/76274.html

-

Comprehensive Guide To HDPE Pipes and Fittings | Durable & Sustainable Solutions

NewsNov.24,2025

-

HDPE Culvert Pipe – Durable, Flexible & Sustainable Infrastructure Solutions

NewsNov.24,2025

-

DWC HDPE Pipe – Durable, Cost-Effective Drainage and Conduit Solutions

NewsNov.23,2025

-

HDPE Drainage Pipe – Durable and Sustainable Water Management Solutions

NewsNov.23,2025

-

Durable and Sustainable HDPE Corrugated Pipe Solutions for Modern Infrastructure

NewsNov.23,2025

-

HDPE Water Pipe - Durable, Cost-Effective Water Solutions for Global Needs

NewsNov.22,2025