Jul . 24, 2025 08:01 Back to list

High Quality PVC Soft Sheet for Flexible Applications | Durable & Customizable

PVC soft sheet is a pivotal material in modern manufacturing and industrial sectors, offering flexibility, durability, and a wide range of applications. This complete guide explores cutting-edge trends, technical parameters, industrial usage, and authoritative perspectives to help you make informed decisions when sourcing PVC soft sheet.

About Lida Plastic | Leading PVC Soft Sheet Manufacturer

As a reputable supplier and expert in PVC soft sheet production, Lida Plastic delivers products tailored to global industry standards. Visit our official website for full product listings and technical documentation.

- Tel: 0086-312-5381013

- Email: lidaplastic@ldsy.cn

- Mobile/WhatsApp: 0086-17731201156

- Address: No.316 Pingan West Street, Shunping County, Baoding City, Hebei, China 072250

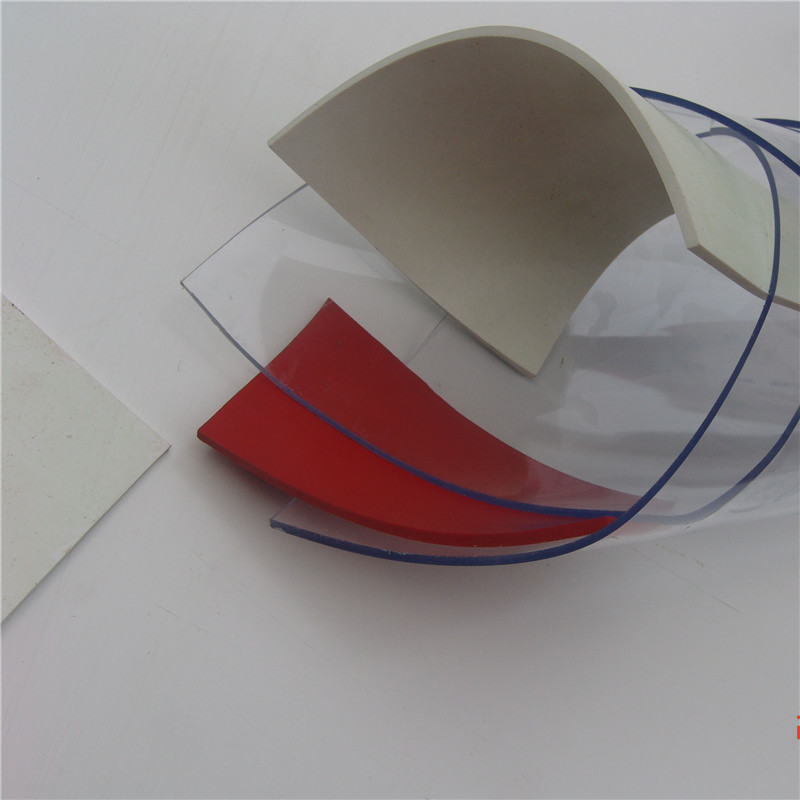

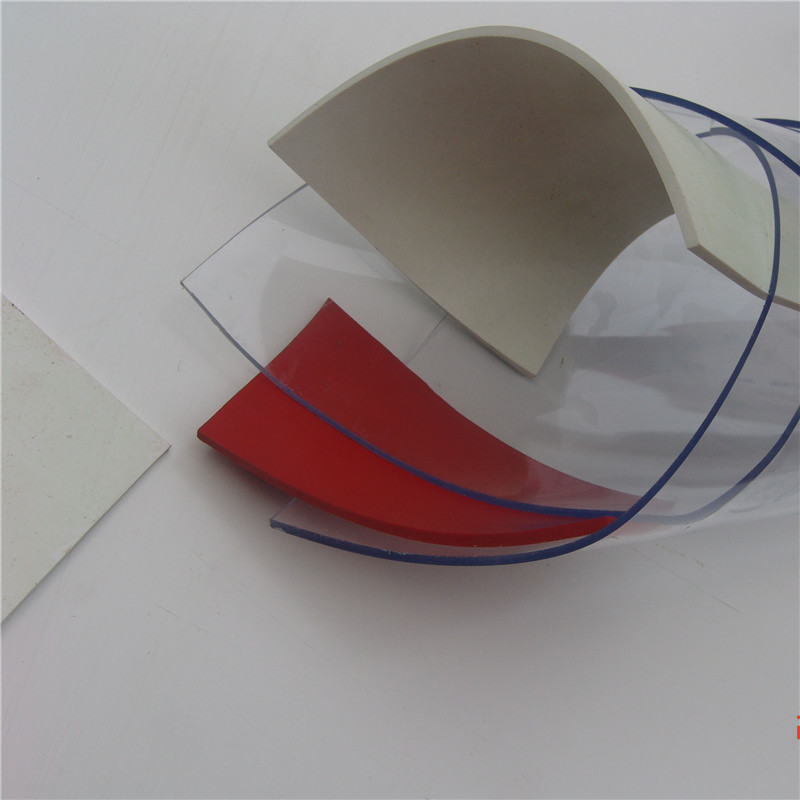

Product: PVC soft sheet

Short Description: Sizes: Thickness range: 2mm~6mm; Width: 1000mm~1300mm; Length: Any length; Surface: glossy; Standard Colors: White, green.

Product link: PVC soft sheet

Short Description: Sizes: Thickness range: 2mm~6mm; Width: 1000mm~1300mm; Length: Any length; Surface: glossy; Standard Colors: White, green.

Product link: PVC soft sheet

Understanding PVC Soft Sheet: Industry Overview & Trends

PVC soft sheet is a flexible form of polyvinyl chloride that stands out for its excellent impact resistance, chemical stability, and transparency or color-customizable appearance. Its production utilizes advanced calendaring technologies to ensure consistent thickness and durability. According to the ScienceDirect engineering portal, the adoption of PVC soft sheet has accelerated in recent years, especially in the healthcare, packaging, and construction industries due to its non-toxic and versatile nature.

With environmental regulations becoming stricter and the market seeking eco-friendly yet high-performance materials, PVC soft sheet manufacturers are embracing lead-free stabilizers, improved plasticizer formulas, and sustainable additives.

Recent industry data indicates the global PVC soft sheet market is poised for significant growth, fueled by advanced product development and expansion in automotive and medical applications (Plastics News).

Recent industry data indicates the global PVC soft sheet market is poised for significant growth, fueled by advanced product development and expansion in automotive and medical applications (Plastics News).

Why Choose Lida Plastic’s PVC Soft Sheet?

As an industry leader, Lida Plastic provides custom solutions backed by ISO-certified quality management. Our PVC soft sheet products are developed with reference to stringent international standards to ensure reliability and performance under diverse operating conditions.

As an industry leader, Lida Plastic provides custom solutions backed by ISO-certified quality management. Our PVC soft sheet products are developed with reference to stringent international standards to ensure reliability and performance under diverse operating conditions.

PVC Soft Sheet Technical Parameters (Industry Standards)

| Technical Parameter | Typical Range / Value | Industry Standard (EN, ASTM) | Remarks |

|---|---|---|---|

| Thickness | 2mm ~ 6mm | EN ISO 1183-1, ASTM D1593 | Customizable by project |

| Width | 1000mm ~ 1300mm | ISO 4592-1 | Large seamless rolls available |

| Length | Any length (custom roll) | EN ISO 291 | Uncut for bulk needs |

| Surface | Glossy | EN ISO 2813 | Matte available upon request |

| Standard Color | White, Green | ISO 11664-4 | Custom color matching |

| Density | 1.22~1.35g/cm³ | ISO 1183-1 | Depends on plasticizer |

| Hardness (Shore A) | 60~85 | ISO 868 | Soft to medium grades |

| Tensile Strength | 11~18 MPa | ISO 527 | Suitable for forming |

| Elongation at break | 200%~350% | ISO 527 | Excellent flexibility |

| Fire Resistance | UL 94 V-2 | UL 94 | Self-extinguishing |

| Operating Temperature | -15°C to 60°C | EN 1876 | Standard working condition |

| Chemical Resistance | Excellent (acids, alkali) | ISO/TR 10358 | Wide spectrum chemicals |

Data Visualization: PVC Soft Sheet Technical Parameter Trends

Key Applications of PVC Soft Sheet

The adaptability of PVC soft sheet has enabled its widespread adoption across numerous industries:

- Medical & Pharmaceutical: IV bags, blood bags, flexible tubing, device packaging (PMCID: PMC8380969).

- Construction: Waterproofing membranes, vibration damping sheets, partition curtains.

- Automotive: Interior and trunk linings, sound absorption mats.

- Packaging: Food-grade films, shrink sleeves, protective coverings.

- Electronics: Insulation, protective films, antistatic sheets.

- Home Furnishings: Tablecloths, shower curtains, decorative films.

- Industrial: Acid-resistant linings, conveyor curtains, gasket fabrications.

Professional FAQ: In-depth on PVC Soft Sheet Terminology

Q1: What is the primary raw material for PVC soft sheet?

A1: The main raw material is polyvinyl chloride (PVC) resin combined with plasticizers, stabilizers, pigments, and functional additives. This blend allows superior flexibility and chemical resistance.

Q2: What are the available thicknesses and how are they selected?

A2: Typical thickness ranges from 2mm to 6mm. Selection depends on end application requirements such as structural strength, flexibility, and processing method.

Q3: What are the international standards applicable to PVC soft sheet?

A3: Standards include ISO 1183 (Density), ISO 527 (Tensile & Elongation), ISO 868 (Shore Hardness), EN ISO 291 (Dimensions), and UL 94 (Fire Resistance).

Q4: How does the surface finish impact usage?

A4: Glossy finishes provide aesthetic appeal and easy cleaning, ideal for medical and packaging uses, while matte finishes reduce glare and improve tactile comfort for furnishings.

Q5: How is PVC soft sheet installed or processed?

A5: Sheets can be cut, welded (hot air or RF), sewn, or glued. Installation standards require clean, dry surfaces and, for room partitions, adherence to fire safety codes.

Q6: What determines hardness and flexibility?

A6: The ratio of plasticizer to resin mainly determines hardness (Shore A) and flexibility. Products can range from very soft (60 Shore A) to semi-rigid (up to 85 Shore A).

Q7: Is PVC soft sheet safe for food or medical contact?

A7: Yes, when produced with certified food/medical-grade plasticizers and stabilizers under ISO 9001/13485, PVC soft sheet meets relevant FDA, REACH, and EU standards for direct contact.

Authority, Expertise, and Trust in PVC Soft Sheet Manufacturing

As demonstrated by references in TAPPI Journal and Plastics News, quality control, advanced compounding, and continuous material testing are non-negotiable standards. Lida Plastic adheres to ISO management, complete traceability, and regular batch sampling to deliver PVC soft sheet products with the highest levels of reliability and safety.

The company's decade-long production expertise, R&D capacity, and technical partnerships with industry leaders ensure that each PVC soft sheet batch meets exacting specifications for both domestic and export clients.

The company's decade-long production expertise, R&D capacity, and technical partnerships with industry leaders ensure that each PVC soft sheet batch meets exacting specifications for both domestic and export clients.

Ready for a Professional PVC soft sheet solution?

Please contact Lida Plastic at 0086-312-5381013, email: lidaplastic@ldsy.cn, or Mobile/WhatsApp: 0086-17731201156.

Address: No.316 Pingan West Street, Shunping County, Baoding City, Hebei, China 072250.

Please contact Lida Plastic at 0086-312-5381013, email: lidaplastic@ldsy.cn, or Mobile/WhatsApp: 0086-17731201156.

Address: No.316 Pingan West Street, Shunping County, Baoding City, Hebei, China 072250.

Conclusion: Professional Insights & Further Reading

The global adoption of PVC soft sheet will continue to expand thanks to its customizable performance, recyclability, and affordability. For comprehensive sourcing, product development, or technical support, always choose a manufacturer adhering to the latest international standards—like Lida Plastic.

Authoritative References:

Authoritative References:

Share:

Latest news

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025