jan . 19, 2025 03:50 Back to list

pvc plastic welding rod

PVC plastic welding rods are a crucial component in a variety of industrial applications, providing durability and flexibility in the fusion and repair of PVC materials. This article delves into the essential aspects of using PVC welding rods, sharing detailed insights based on extensive field experience, professional expertise, and industry best practices to offer authoritative guidance for users.

Another challenge is achieving consistent heat distribution, especially on irregular surfaces or in hard-to-reach areas. Employing nozzles of various shapes and conducting practice welds can help practitioners develop the technique necessary to ensure even application of heat and pressure. Authoritative Advice for Best Practices Adhering to best practices is critical in maximizing the efficiency and longevity of PVC welding. It is advisable to conduct regular maintenance of welding equipment to prevent operational faults. Consistent inspection of the welding rod for any impurities or defects before usage is also essential, as imperfections can drastically compromise the quality of the weld. Additionally, maintaining a controlled environment, free from excessive moisture and temperature fluctuations, can stabilize the welding process and enhance results. Documenting each welding job's specifications and outcomes contributes to establishing protocols that can be refined over time based on success rates and lessons learned. Trustworthiness and Safety Considerations Building trustworthiness in PVC welding involves committing to safety standards meticulously. Proper training for workers and adherence to safety guidelines ensures not only personal safety but also the structural integrity of the welded product. Transparent safety measures and regular audits can enhance trust between contractors and clients. Investing in personal protective equipment (PPE) and ensuring equipment is up-to-date with the latest safety features protects staff and ensures compliance with local safety regulations. Establishing a culture of safety within teams fosters trust and encourages ongoing improvement in welding practices. In conclusion, PVC plastic welding rods are indispensable for industries that rely on strong, durable PVC connections. By leveraging professional expertise, field experience, and an unwavering commitment to quality and safety, businesses can ensure that their welding processes meet the highest standards of performance and reliability. This comprehensive approach not only optimizes outcomes but also establishes a respected position in the industry landscape.

Another challenge is achieving consistent heat distribution, especially on irregular surfaces or in hard-to-reach areas. Employing nozzles of various shapes and conducting practice welds can help practitioners develop the technique necessary to ensure even application of heat and pressure. Authoritative Advice for Best Practices Adhering to best practices is critical in maximizing the efficiency and longevity of PVC welding. It is advisable to conduct regular maintenance of welding equipment to prevent operational faults. Consistent inspection of the welding rod for any impurities or defects before usage is also essential, as imperfections can drastically compromise the quality of the weld. Additionally, maintaining a controlled environment, free from excessive moisture and temperature fluctuations, can stabilize the welding process and enhance results. Documenting each welding job's specifications and outcomes contributes to establishing protocols that can be refined over time based on success rates and lessons learned. Trustworthiness and Safety Considerations Building trustworthiness in PVC welding involves committing to safety standards meticulously. Proper training for workers and adherence to safety guidelines ensures not only personal safety but also the structural integrity of the welded product. Transparent safety measures and regular audits can enhance trust between contractors and clients. Investing in personal protective equipment (PPE) and ensuring equipment is up-to-date with the latest safety features protects staff and ensures compliance with local safety regulations. Establishing a culture of safety within teams fosters trust and encourages ongoing improvement in welding practices. In conclusion, PVC plastic welding rods are indispensable for industries that rely on strong, durable PVC connections. By leveraging professional expertise, field experience, and an unwavering commitment to quality and safety, businesses can ensure that their welding processes meet the highest standards of performance and reliability. This comprehensive approach not only optimizes outcomes but also establishes a respected position in the industry landscape.

Share:

Next:

Latest news

-

Premium PVC Soft Sheets: Clear, Flexible & Durable

NewsAug.12,2025

-

Premium PVC Round Rods: Durable, Chemical Resistant, Easy to Machine

NewsAug.11,2025

-

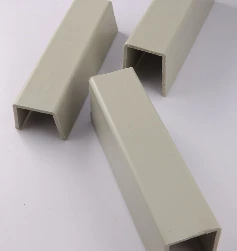

PP U-channel: Chemical-Resistant, Lightweight & Durable

NewsAug.10,2025

-

Transparent PVC Pipe: Clear Flexible Tubing for Fluids

NewsAug.09,2025

-

Durable PP Rigid Sheet: Versatile & High-Quality Plastic Panels

NewsAug.08,2025

-

Premium Glossy PP Rigid Sheet – Durable & Versatile

NewsAug.07,2025