Nov . 06, 2025 14:50 Back to list

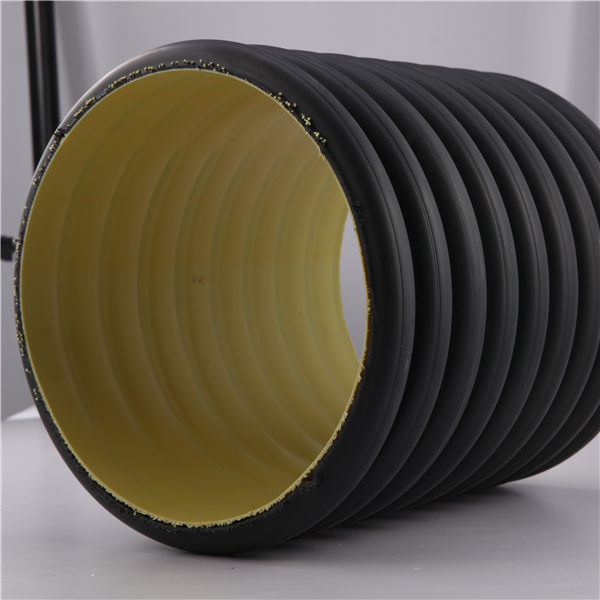

HDPE Double Wall Corrugated Pipe - Durable, Leakproof, Light

Field Notes on the HDPE Double Wall Corrugated Pipe Market

If you work around stormwater or sewer assets long enough, you start to notice what survives a nasty freeze-thaw cycle, a surprise axle load, or a hurried backfill. The short version: the HDPE Double Wall Corrugated Pipe keeps showing up on the punch list—in a good way. It’s co-extruded: smooth inner wall for flow, trapezoidal corrugations outside for stiffness, with a hollow layer in between. Light, strong, forgiving during installation. Many customers say it’s the best antidote to schedule risk when the trench throws a curveball.

Where the industry is heading

Two trends are obvious right now: tighter stormwater quality regs and pressure to decarbonize materials. Structured-wall polyethylene ticks both boxes—lower embodied energy than concrete and ductile performance that reduces repair calls. We’re also seeing more demand for larger diameters (DN800–1200) in culverts and detention, plus quick-turn customization (perforations, sockets, color stripes) for big site packages.

What it’s made of and how it’s built

- Material: high-density polyethylene (HDPE) with carbon black ≈2–3% for UV stability, antioxidant package, and sometimes a white/light inner layer for CCTV visibility.

- Process flow: resin drying → twin co-extrusion → vacuum forming of corrugations → on-line sizing/cooling → socketing → automatic cut-to-length → ring stiffness check → marking & packing.

- Inner wall: smooth bore to reduce Manning’s n; outer wall: trapezoidal corrugation for ring stiffness and impact resistance.

- Service life: around 50+ years in buried non-pressure drainage when installed per standard practices (real-world use may vary).

Testing, standards, and typical data

Manufacturers typically validate to ISO 9969 (ring stiffness), EN 13476/ISO 21138 (structured-wall systems), and—where applicable—AASHTO M 294 or ASTM F2306 for corrugated HDPE. Routine checks include ring stiffness SN4/SN8/SN12.5, impact resistance (e.g., ASTM D2444), dimensions (ISO 3126), and melt flow (ISO 1133).

Product specifications (typical)

| Nominal Size (DN) | Ring Stiffness | Effective Length | Joint | Weight ≈ (kg/m) |

|---|---|---|---|---|

| DN200 | SN4 / SN8 | 6 m (±1%) | Bell with EPDM ring | 2.5–3.2 |

| DN400 | SN8 / SN12.5 | 6 m | Bell with EPDM ring | 7.8–9.6 |

| DN800 | SN8 / SN12.5 | 6 m | Bell with EPDM ring | 21–26 |

Note: Values are indicative; refer to project submittals and test certificates for exact figures.

Where it’s used (and why)

- Municipal drainage and sewer (gravity lines, manhole connections).

- Stormwater: culverts, retention/detention, highway runoff—low Manning’s n helps.

- Industrial parks, mining drains, agriculture irrigation/underdrains.

- Cable protection ducts where impact resistance matters.

Pros that keep getting mentioned: high ring stiffness-to-weight ratio, fast installation, good bend radius, solid UV stability, and notably low noise transmission in building drainage (surprisingly noticeable in multi-story retrofits).

Vendor snapshot and customization

From No.316 Pingan West Street, Shunping County, Baoding, Hebei (China 072250), Lida Plastic offers quick tooling tweaks—perforations, colored ID layers, custom SN classes, and sockets matched to local gasket profiles. Lead times, to be honest, vary with resin markets; still, the flexibility is handy for phased jobs.

| Vendor | Certs/Standards | Size Range | Customization | Typical Lead Time |

|---|---|---|---|---|

| Lida Plastic | ISO 9001; ISO 9969; EN 13476 alignment | DN110–DN1200 | Perforations, color stripe, SN4–SN12.5, custom sockets | ≈ 7–15 days |

| Supplier A | AASHTO M 294; ASTM F2306 | DN150–DN900 | Color stripe; limited perforations | ≈ 10–20 days |

| Supplier B | ISO 21138; ISO 9969 | DN200–DN1000 | SN classes; sockets | ≈ 12–25 days |

Case notes

Municipal retrofit, Baoding: DN600 SN8 lines for a mixed-use district. CCTV at 12 months showed clean joints and low silt; crews liked the lighter lifts (two people could maneuver a stick safely).

Industrial park, SE Asia: DN800 culvert replaced cracked concrete. Installation time dropped by roughly 30%, and post-monsoon deflection stayed under 3% (ASTM D2412 check, contractor’s gauge data).

Final thought

Actually, the appeal of the HDPE Double Wall Corrugated Pipe isn’t mysterious: dependable stiffness, smooth hydraulics, and less drama during install. In a world of tight windows and tighter budgets, that’s hard to argue with.

References

- ISO 9969: Thermoplastics pipes—Determination of ring stiffness.

- EN 13476 / ISO 21138: Plastics piping systems for non-pressure underground drainage and sewerage—Structured-wall piping systems.

- AASHTO M 294: Corrugated polyethylene drainage pipe.

- ASTM F2306/F2306M: Corrugated HDPE pipe and fittings for gravity-flow.

- ISO 3126: Plastics pipes—Measurement of dimensions.

-

Durable and Efficient Sprinkler HDPE Pipe Solutions for Global Water Management

NewsNov.19,2025

-

Durable and Efficient HDPE Irrigation Pipe Fittings for Sustainable Water Management

NewsNov.19,2025

-

Efficient and Durable HDPE Pipe Sprinkler Systems for Modern Irrigation

NewsNov.18,2025

-

Durable and Efficient HDPE Sprinkler Pipe Fittings for Global Water Systems

NewsNov.18,2025

-

HDPE Sprinkler Pipe – Durable, Efficient Irrigation Solutions for Global Use

NewsNov.18,2025

-

Comprehensive Guide to PVC Pipe Coupling: Durable, Cost-Effective Piping Connections

NewsNov.17,2025