Feb . 07, 2025 05:07 Back to list

HDPE drainage and irrigation pipe

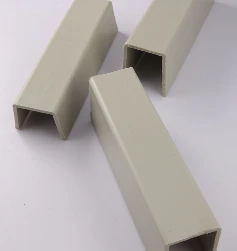

The rise in popularity of thermoplastic welding rods is no accident. These vital components are becoming increasingly indispensable across various industries, from automotive and construction to marine and beyond. Navigating the world of thermoplastic welding rods demands both expertise and practical understanding to ensure optimal performance in different applications.

The sheer adaptability of thermoplastic welding rods across diverse domains speaks to their importance. In the automotive industry, for instance, these rods are used for repairing bumpers and plastic components, offering a cost-effective alternative to part replacement. The construction sector leverages these rods for sealing and joining materials in water containment structures, while the marine industry utilizes them for boat repair and maintenance. Being an authoritative figure in the world of thermoplastic welding rods also involves staying informed about innovations and developments. The introduction of eco-friendly biodegradable thermoplastic materials and advancements in welding technology can offer new avenues for enhanced sustainability and efficiency. Keeping abreast of these changes ensures that professionals can offer modern solutions that align with evolving industry standards. Establishing trustworthiness in the application of thermoplastic welding rods involves transparency and consistent delivery of results. Documenting successful projects, maintaining certifications, and prioritizing client education all contribute to building credibility. Clients are more likely to trust vendors who can demonstrate a track record of handling similar projects with precision and reliability. To conclude, delving into thermoplastic welding rods requires more than just basic knowledge. It demands an integration of experience, expertise, authority, and reliability. By embodying these principles, professionals and businesses can unlock the full potential of thermoplastic welding, driving success across a myriad of applications while setting new benchmarks for industry excellence.

The sheer adaptability of thermoplastic welding rods across diverse domains speaks to their importance. In the automotive industry, for instance, these rods are used for repairing bumpers and plastic components, offering a cost-effective alternative to part replacement. The construction sector leverages these rods for sealing and joining materials in water containment structures, while the marine industry utilizes them for boat repair and maintenance. Being an authoritative figure in the world of thermoplastic welding rods also involves staying informed about innovations and developments. The introduction of eco-friendly biodegradable thermoplastic materials and advancements in welding technology can offer new avenues for enhanced sustainability and efficiency. Keeping abreast of these changes ensures that professionals can offer modern solutions that align with evolving industry standards. Establishing trustworthiness in the application of thermoplastic welding rods involves transparency and consistent delivery of results. Documenting successful projects, maintaining certifications, and prioritizing client education all contribute to building credibility. Clients are more likely to trust vendors who can demonstrate a track record of handling similar projects with precision and reliability. To conclude, delving into thermoplastic welding rods requires more than just basic knowledge. It demands an integration of experience, expertise, authority, and reliability. By embodying these principles, professionals and businesses can unlock the full potential of thermoplastic welding, driving success across a myriad of applications while setting new benchmarks for industry excellence.

Share:

Next:

Latest news

-

High-Quality HDPE Sheet | Durable Plastic Panels

NewsAug.06,2025

-

High-Precision PVC Rigid Sheets for Vacuum Forming | AI-Optimized

NewsAug.05,2025

-

Durable PVC-M Water Supply Pipes | 60-Year Life

NewsAug.04,2025

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025

-

HDPE Drainage & Irrigation Pipe - Durable, Efficient Solutions

NewsAug.01,2025