Oct . 10, 2025 12:50 Back to list

PP rigid sheet(glossy surface): Need high-gloss, food-safe?

A Field Note on PP Rigid Sheet with a Glossy Edge

If you’ve ever spec’d plastic for chemical tanks, clean-room liners, or signage that needs to look sharp yet shrug off abuse, you’ve likely crossed paths with PP rigid sheet(glossy surface). Coming out of No.316 Pingan West Street, Shunping County, Baoding City, Hebei, China 072250, I’ve seen these sheets evolve from “workhorse commodity” to “precision material” territory. And yes, the glossy finish isn’t just vanity—it signals process control on the polishing stack.

What’s trending (and why it matters)

Industry chatter says: higher demand in chemical processing, lab infrastructure, battery production, and food handling. Why PP? It’s tough, weldable, and resists a wide range of acids and bases. The glossy-surface variant is gaining traction in display, medical device housings, and facilities that value cleanability. Also, recyclability is a big plus—many customers say it’s easier to hit sustainability targets with PP than with PVC.

Core specs at a glance

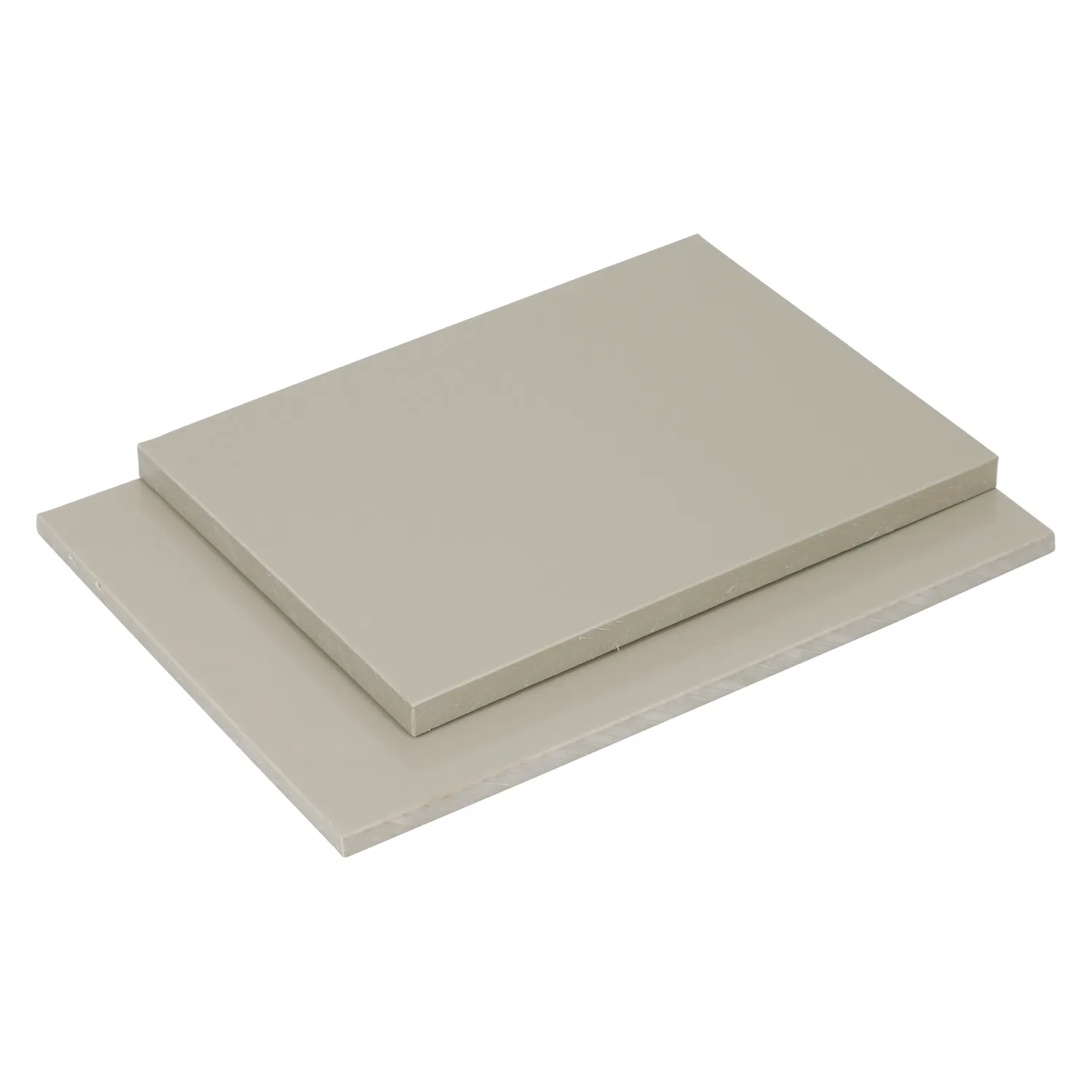

| Thickness range | 2–40 mm |

| Width (2–20 mm) | 1000–2400 mm |

| Width (25–40 mm) | 1000–1500 mm |

| Length | Any length; cut-to-size service available |

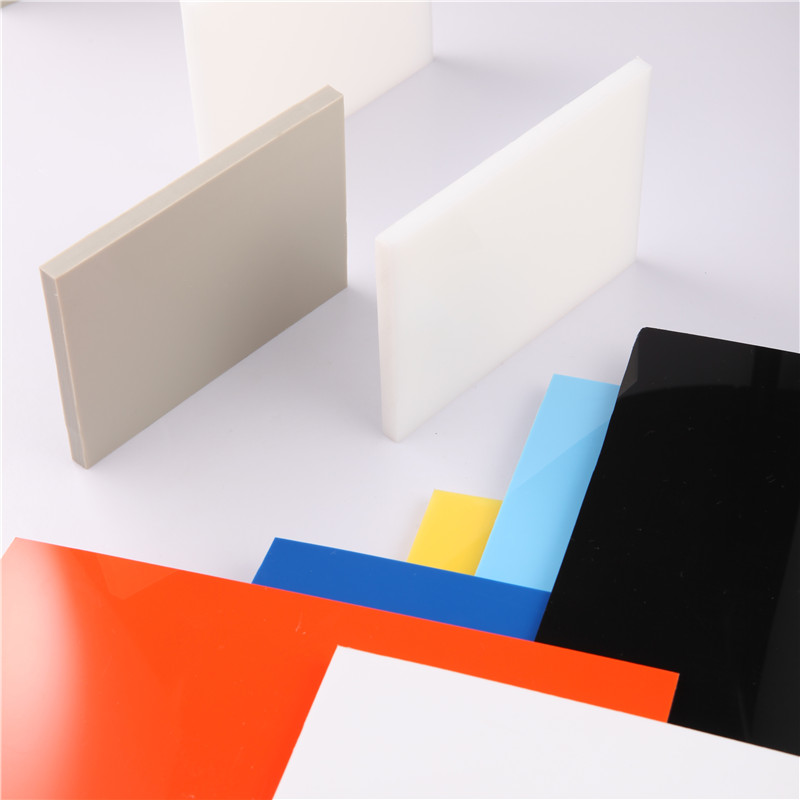

| Surface / Colors | Glossy; Natural, Grey (RAL7032), Black, Light Blue, Yellow, custom |

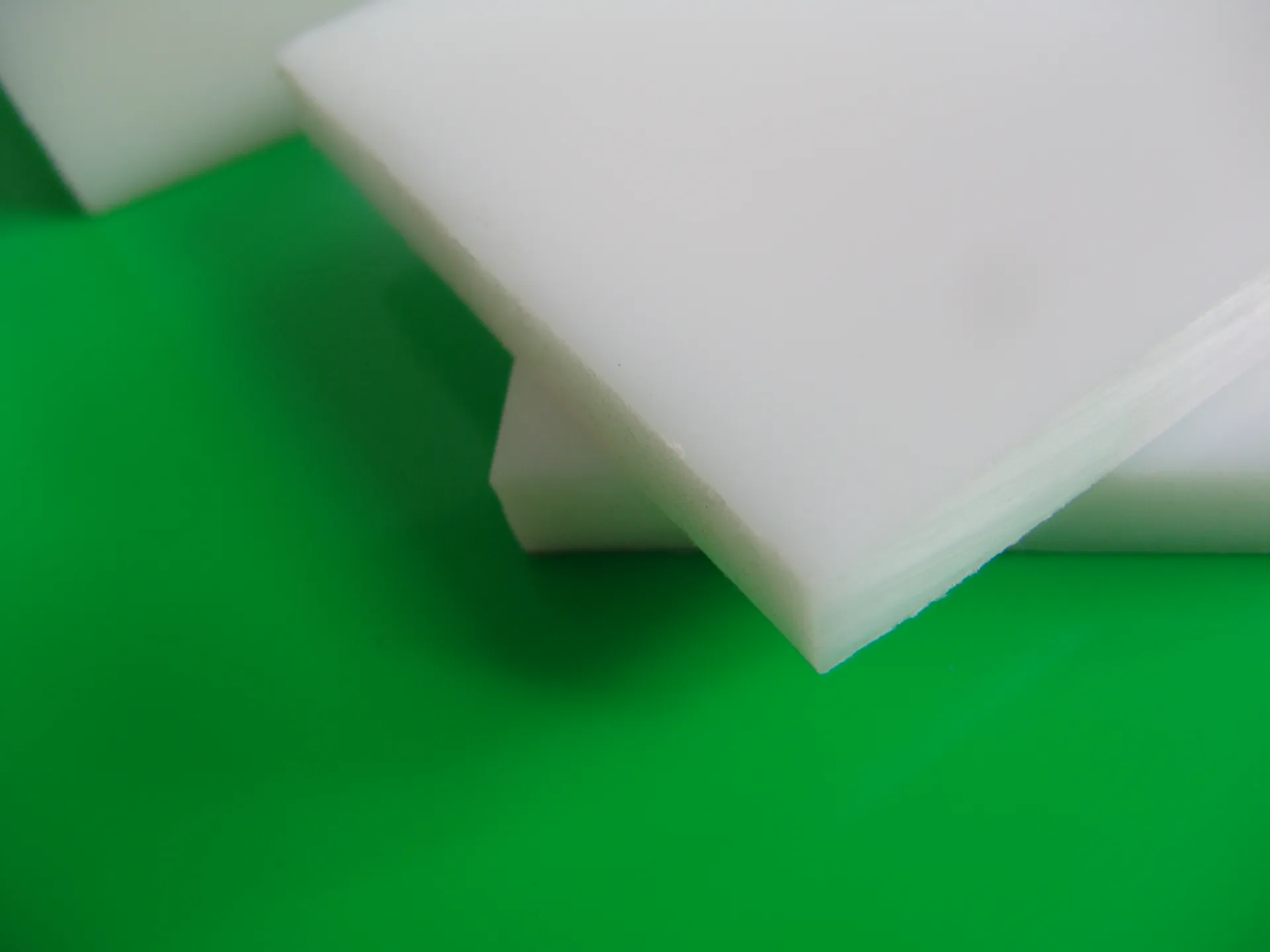

| Material | Polypropylene homopolymer or random copolymer (≈1–4% ethylene); options: modified, reinforced, PP electrode |

Representative material data (real-world use may vary)

| Property | Typical | Standard |

|---|---|---|

| Density | ≈0.90 g/cm³ | ASTM D792 / ISO 1183 |

| Tensile strength | ≈28–35 MPa | ASTM D638 |

| Flexural modulus | ≈1.3–1.6 GPa | ISO 178 |

| Vicat softening | ≈150°C | ISO 306 |

| Flammability | UL 94 HB | UL 94 |

| Gloss (60°) | ≈75–90 GU | ASTM D523 |

Process flow and QC

- Resin selection: homopolymer for stiffness, random copolymer for impact (ethylene ≈1–4%).

- Compounding: optional UV stabilizers, pigments, antistats, or glass/mineral reinforcement.

- Extrusion: sheet die + polished calendar stack to achieve the glossy surface.

- Annealing: to reduce internal stress and improve flatness.

- Finishing: cut-to-size, CNC, welding rods (PP electrode) matched.

- Testing: MFR (ISO 1133), thickness/flatness, tensile (ASTM D638), impact (ISO 179), density (ASTM D792), gloss (ASTM D523).

Service life: indoors 8–10 years; outdoors ≈2–5 years (UV-stabilized: ≈5–8). Food-contact variants can comply with FDA 21 CFR 177.1520 and EU frameworks, pending grade selection.

Applications we keep seeing

- Chemical tanks, plating lines, fume hood liners, pipe flanges.

- Medical and lab furniture, clean-room panels, orthotic forms.

- Point-of-sale displays, signage, machine guards with a crisp gloss.

- Food processing spacers, trays (grade-dependent compliance).

- Semiconductor wet benches, acid-resistant ducts.

Note on joining: adhesives are tricky with PP; thermal welding or mechanical fastening is the reliable path.

Vendor snapshot

| Vendor | Certs | Tolerance | Lead time | Color match | Services |

|---|---|---|---|---|---|

| Lida (Hebei) | ISO 9001; RoHS/REACH statements | ≈ ±0.2–0.5 mm (thickness-dependent) | Fast (stock + custom) | RAL/Pantone capable | Cut-to-size, welding rods, CNC |

| Generic Importer | Varies | ≈ ±0.5–0.8 mm | Medium | Limited | Basic cutting |

| Local Fabricator | Shop-level | ≈ ±0.5 mm | Quick for small runs | Good on small batches | Prototyping, machining |

Customization and real-world notes

Custom colors, anti-static modifiers, UV packages, and reinforced grades are common. Many buyers ask for matched PP welding rods to keep weld seams clean on PP rigid sheet(glossy surface). In practice, we see reduced chemical attack vs. PVC in alkaline settings and better machinability than HDPE for crisp edges.

Quick case notes

Plating line retrofit: Switching to PP rigid sheet(glossy surface) for tank cladding cut chemical staining and made wipe-downs faster; a maintenance manager told me “cleanup went from hours to minutes.”

Retail display house: Gloss PP panels replaced acrylic in back-of-house fixtures; impact dings dropped and panels stayed presentable longer.

Compliance and references

Typical documentation available: ISO 9001, RoHS, REACH, UL 94 HB classification, and—grade permitting—FDA food-contact declarations. Testing commonly follows ASTM/ISO norms listed above.

Citations

-

Comprehensive Guide To HDPE Pipes and Fittings | Durable & Sustainable Solutions

NewsNov.24,2025

-

HDPE Culvert Pipe – Durable, Flexible & Sustainable Infrastructure Solutions

NewsNov.24,2025

-

DWC HDPE Pipe – Durable, Cost-Effective Drainage and Conduit Solutions

NewsNov.23,2025

-

HDPE Drainage Pipe – Durable and Sustainable Water Management Solutions

NewsNov.23,2025

-

Durable and Sustainable HDPE Corrugated Pipe Solutions for Modern Infrastructure

NewsNov.23,2025

-

HDPE Water Pipe - Durable, Cost-Effective Water Solutions for Global Needs

NewsNov.22,2025