Feb . 10, 2025 21:58 Back to list

PVC-M water supply pipe

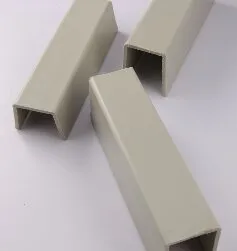

HDPE conduit pipes are rapidly becoming indispensable in a wide range of industries, offering unparalleled advantages when it comes to underground cable protection and high-density pipeline installations. These conduits, made from high-density polyethylene (HDPE), are valued for their robustness, flexibility, and longevity, providing a reliable solution that meets the stringent demands of modern infrastructure projects.

In terms of environmental concerns, HDPE is highly regarded for its eco-friendliness. It is a recyclable material, aligning with the growing demand for sustainable construction practices. Given its longer lifespan and reduced need for replacement, HDPE conduits minimize environmental impacts, making them a preferred option for eco-conscious companies and regulatory bodies pushing for greener solutions. The application of HDPE conduit pipes extends beyond infrastructural installations to telecommunication and power industries. In telecommunications, where high data transmission reliability is paramount, HDPE conduit provides seamless protection for fiber optic cables, ensuring uninterrupted service and minimal signal loss. Similarly, in the power industry, these conduits are crucial in safeguarding electrical cables from environmental and mechanical damages. Companies opting for HDPE conduits often find that the initial investment is balanced by long-term savings. The durability, reduced maintenance needs, efficient installation, and environmental benefits collectively contribute to the long-term economic viability of these conduits. Furthermore, in safety-sensitive applications, HDPE's non-conductive properties offer an additional layer of protection, reducing the risk of electrical hazards. In conclusion, the rise in popularity of HDPE conduit pipes in construction and utility sectors is no coincidence. Their impressive combination of durability, flexibility, thermal stability, cost-effectiveness, and eco-friendliness sets them apart as a superior choice for pipelines and cable protection systems. Professionals seeking to implement efficient, reliable, and sustainable infrastructure solutions continually turn to HDPE conduits for these compelling reasons, establishing them as a cornerstone in modern engineering applications. Thus, the expertise and insight into HDPE conduit pipes reflect not just a material choice, but a strategic investment in the future of infrastructure resilience and reliability.

In terms of environmental concerns, HDPE is highly regarded for its eco-friendliness. It is a recyclable material, aligning with the growing demand for sustainable construction practices. Given its longer lifespan and reduced need for replacement, HDPE conduits minimize environmental impacts, making them a preferred option for eco-conscious companies and regulatory bodies pushing for greener solutions. The application of HDPE conduit pipes extends beyond infrastructural installations to telecommunication and power industries. In telecommunications, where high data transmission reliability is paramount, HDPE conduit provides seamless protection for fiber optic cables, ensuring uninterrupted service and minimal signal loss. Similarly, in the power industry, these conduits are crucial in safeguarding electrical cables from environmental and mechanical damages. Companies opting for HDPE conduits often find that the initial investment is balanced by long-term savings. The durability, reduced maintenance needs, efficient installation, and environmental benefits collectively contribute to the long-term economic viability of these conduits. Furthermore, in safety-sensitive applications, HDPE's non-conductive properties offer an additional layer of protection, reducing the risk of electrical hazards. In conclusion, the rise in popularity of HDPE conduit pipes in construction and utility sectors is no coincidence. Their impressive combination of durability, flexibility, thermal stability, cost-effectiveness, and eco-friendliness sets them apart as a superior choice for pipelines and cable protection systems. Professionals seeking to implement efficient, reliable, and sustainable infrastructure solutions continually turn to HDPE conduits for these compelling reasons, establishing them as a cornerstone in modern engineering applications. Thus, the expertise and insight into HDPE conduit pipes reflect not just a material choice, but a strategic investment in the future of infrastructure resilience and reliability.

Share:

Latest news

-

High-Precision PVC Rigid Sheets for Vacuum Forming | AI-Optimized

NewsAug.05,2025

-

Durable PVC-M Water Supply Pipes | 60-Year Life

NewsAug.04,2025

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025

-

Premium PP Welding Rod: GPT-4 Turbo Enhanced

NewsAug.01,2025

-

HDPE Drainage & Irrigation Pipe - Durable, Efficient Solutions

NewsAug.01,2025