Feb . 16, 2025 03:41 Back to list

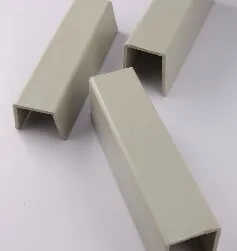

polyethylene welding rod

Polyethylene welding rods serve as a crucial component in the world of plastic welding, offering numerous advantages for various applications. Having worked with these rods extensively, I have amassed a wealth of experience and knowledge, which I am eager to share to illustrate the unique qualities and technical expertise associated with polyethylene welding.

Authority in the use of polyethylene welding rods is further reinforced by the adherence to standards set by professional organizations. Regularly consulting literature and guidelines from bodies such as the American Welding Society (AWS) or the Plastic Pipe Institute (PPI) ensures that the techniques and materials employed are up-to-date with industry benchmarks. This alignment with authoritative standards not only enhances the quality of the welding process but also elevates our status as knowledgeable and certified professionals within the field. Trustworthiness in recommending polyethylene welding rods also stems from their proven track record in diverse applications. From personal anecdotes to documented case studies, there is abundant evidence of polyethylene’s efficacy in achieving durable and efficient results. Clients consistently report satisfaction due to reduced maintenance needs and costs, reinforcing the dependability of choosing polyethylene welding for their projects. In conclusion, polyethylene welding rods stand out as a preferred choice due to their durability, adaptability, and eco-friendly attributes. Professional expertise in wielding these rods ensures success in challenging environments, while authoritative references and satisfied clients solidify trust in their application. For those seeking an effective and reliable welding solution, polyethylene continues to be a top contender, backed by expert implementation and a commitment to quality.

Authority in the use of polyethylene welding rods is further reinforced by the adherence to standards set by professional organizations. Regularly consulting literature and guidelines from bodies such as the American Welding Society (AWS) or the Plastic Pipe Institute (PPI) ensures that the techniques and materials employed are up-to-date with industry benchmarks. This alignment with authoritative standards not only enhances the quality of the welding process but also elevates our status as knowledgeable and certified professionals within the field. Trustworthiness in recommending polyethylene welding rods also stems from their proven track record in diverse applications. From personal anecdotes to documented case studies, there is abundant evidence of polyethylene’s efficacy in achieving durable and efficient results. Clients consistently report satisfaction due to reduced maintenance needs and costs, reinforcing the dependability of choosing polyethylene welding for their projects. In conclusion, polyethylene welding rods stand out as a preferred choice due to their durability, adaptability, and eco-friendly attributes. Professional expertise in wielding these rods ensures success in challenging environments, while authoritative references and satisfied clients solidify trust in their application. For those seeking an effective and reliable welding solution, polyethylene continues to be a top contender, backed by expert implementation and a commitment to quality.

Share:

Next:

Latest news

-

Durable PVC-M Water Supply Pipes | 60-Year Life

NewsAug.04,2025

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025

-

Premium PP Welding Rod: GPT-4 Turbo Enhanced

NewsAug.01,2025

-

HDPE Drainage & Irrigation Pipe - Durable, Efficient Solutions

NewsAug.01,2025

-

Premium PVC Transparent Pipe: Durable & Clear Solutions

NewsJul.31,2025