Aug . 04, 2025 07:40 Back to list

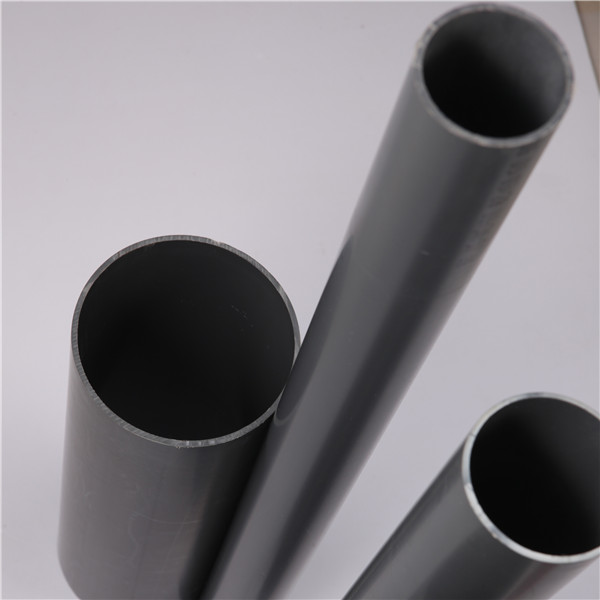

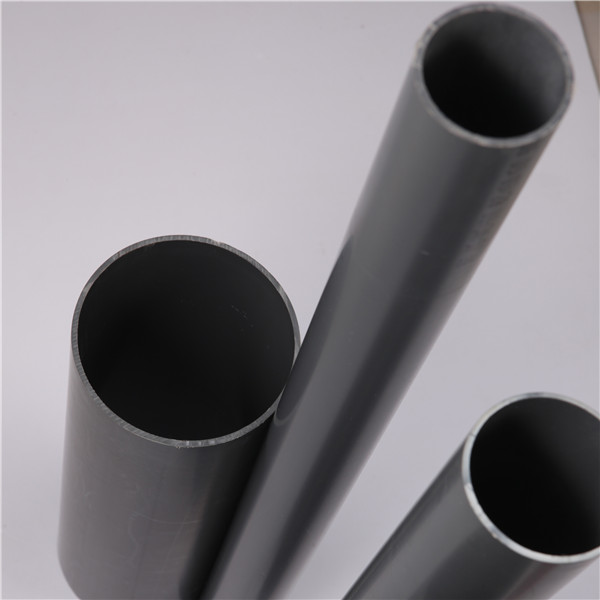

Durable PVC-M Water Supply Pipes | 60-Year Life

PVC-M water supply pipe is redefining the standards of water conveyance with its advanced molecular-oriented structure, superb hydraulic performance, exceptional mechanical properties, and outstanding cost-efficiency.

See product details: PVC-M water supply pipe

1. Industry Overview & Market Trends

The global PVC-M water supply pipe market is swiftly expanding. According to Markets&Markets, the worldwide PVC pipe market is projected to reach USD 85 billion by 2027, with the water supply sector accounting for over 35% of demand, driven by urbanization, aging infrastructure replacement, and accelerating adoption of new-generation pipes like PVC-M in municipal and industrial applications.

2. What is PVC-M Water Supply Pipe?

PVC-M (Modified Polyvinyl Chloride) water supply pipe is a technologically enhanced variant of conventional PVC pipe, wherein specific modifiers (e.g. acrylic, CPE) are incorporated to improve the material's ductility, impact resistance, and stress-crack tolerance. This delivers a unique synergy of lightweight construction, high internal pressure resistance, and sustained hydraulic performance.

Widely used in municipal water systems, industrial process water, agricultural irrigation, fire-fighting mains, and mining, PVC-M water supply pipe complies with global standards such as ISO 1452, EN 1452, ASTM D2241.

3. Manufacturing Process Flow of PVC-M Water Supply Pipe

- Raw Material Mixing: Premium-grade PVC resin, impact modifiers (like CPE, ASA), stabilizers, and additives are blended under precisely controlled conditions.

- Extrusion: Homogenized material is plastified and extruded through an annular die to form the pipe body. Twin-screw extruders ensure consistent gelation and smoothness.

- Vacuum Calibration & Cooling: Pipe enters calibrator and cooling tanks for sizing, dimensional stability, and surface finish.

- Haul-off: Controlled tension and alignment minimize ovality and ensure uniform wall thickness.

- Precision Cutting: Pipes are automatically cut to specified lengths via high-accuracy saws.

- Inspection & Testing: Each batch undergoes ISO 1452, EN 1452, ASTM D2241 compliant hydrostatic test, dimensional inspection, and impact evaluation.

4. Technical Specifications of PVC-M Water Supply Pipe

| Nominal Diameter (mm) | Wall Thickness (mm) | Pressure Rating (PN, MPa) | Burst Pressure (MPa) | Ring Stiffness (kN/m²) | Weight (kg/m) |

|---|---|---|---|---|---|

| 50 | 3.7 | 1.0 | 3.5 | ≥10,000 | 1.55 |

| 110 | 6.6 | 1.25 | 4.2 | ≥10,000 | 4.13 |

| 200 | 9.8 | 1.6 | 5.1 | ≥10,000 | 12.9 |

| 315 | 15.3 | 1.6 | 4.7 | ≥10,000 | 30.2 |

| 400 | 19.6 | 1.25 | 3.9 | ≥10,000 | 45.5 |

Technical Indicators: Performance Comparison

Material Composition Overview

5. Application Scenarios & Industry Advantages

- Urban water delivery & distribution mains

- Potable drinking water supply

- Effluent & reclaimed water transport

- Agricultural irrigation pivots, greenhouses

- Fire-fighting networks & industrial circulation

- Mining dewatering and process lines

- Replacement for ductile iron and steel pipelines

Key Industry Advantages

- Superior Impact and Fatigue Resistance: High modulus ensures pipes withstand dynamic ground movement, water hammer and vibration (ISO 1452-2, EN 1452 certified).

- Lower Installation and Life-Cycle Cost: Lightweight (20-30% less than ductile iron), easier handling, reduced need for heavy machinery and faster assembly with solvent or rubber ring joint systems.

- Outstanding Hydraulic Performance: Smooth internal surface (0.008 mm roughness) maintains flow efficiency, controls pressure losses, and minimizes scaling.

- Chemical Resistance & Corrosion-free: Impervious to soil chemicals, saline, acids, micro-organisms; eliminates expensive external coatings.

- Long Service Life: ≥50 years under continuous pressure (as certified in ISO 9080 long-term hydrostatic stress regression test).

- Eco-Friendly: 100% recyclable, low carbon footprint, RoHS-compliant content.

6. Competitive Benchmark: Major Manufacturers Comparison

| Manufacturer | Region | Certifications | Diameter Range | Main Pressure Class | OEM/Custom Service |

|---|---|---|---|---|---|

| LIDA Plastic | China | ISO 9001, ISO 14001, CE, WRAS | 20 ~ 630 mm | PN6–PN16 | Yes |

| Vinidex | Australia | AS/NZS 4765, WaterMark | 16 ~ 450 mm | PN6–PN16 | Partial |

| Wavin | Europe | EN 1452, DVGW, ISO 9001 | 20 ~ 630 mm | PN10, PN12.5, PN16 | Yes |

| National Plastic | UAE | ISO 1452, WRAS | 16 ~ 400 mm | PN8, PN10, PN12.5 | Yes |

| Sumitomo | Japan | JIS, ISO 14001 | 20 ~ 250 mm | PN6–PN16 | No |

7. Custom Solutions & Project Support

LIDA Plastic offers full-spectrum PVC-M water supply pipe solutions tailored to diverse project requirements:

- Pipe sizing (DN20–630mm), rating, color, and marking customization

- Joint systems: solvent weld, rubber ring, flanged, mechanical (per ISO/EN/DIN)

- System integration: valves, fittings, accessories

- On-site technical assistance, supply chain coordination, and logistics

- Lifecycle monitoring, non-destructive testing, and after-sales tracking

8. Real-World Application Cases

Large Waterworks Pipeline Retrofit (EU, 2023):

- Scope: 28 km DN400-PN12.5 mainline, replaced corroded steel pipelines.

- Achievements: Flow loss reduction by 15%, 12% drop in annual maintenance OPEX, 40% higher shock resistance (post-earthquake inspection, EN1452-2 tested), based on field studies.

Industrial Water Circulation Pipelines (South America, 2022):

- Scope: Chemical plant, DN250–315, 8000m laid in 6 days (23% faster than GRP pipes).

- Result: Zero corrosion failures in 12 months, total energy saving of 7.8% from improved hydraulic efficiency.

Agricultural Drip Irrigation System (Africa, 2021):

- Scope: DN110 and DN160, 9km, replacing galvanized steel.

- Benefits: 70% reduction in leak repair costs, system uptime improved by 19% (local government evaluation report).

9. Certification, Testing & Quality Guarantee

- ISO 1452 / EN 1452 certified for pressure, impact, and long-term hydrostatic performance

- Compliance with WRAS, CE, AS/NZS, DVGW for potable water safety

- 100% 24-hr hydrostatic pressure testing for each batch

- Full traceability and online QC data archiving

- Warranty: 10–15 years manufacturer's warranty (project-specific extension)

Major projects using PVC-M water supply pipe (per WRAS/ISO) report leak reduction rates of 12–65% compared to legacy ductile or steel networks (references: ResearchGate Study).

10. Delivery Cycle, Warranty & Support

- Standard lead time: 7–20 days (Stock/Custom mix depending on specification & order volume)

- Shipment: Palletized bundles, sea/land/rail options, global coverage

- Support: Comprehensive project consulting, on-site or remote engineering assistance, prompt after-sales troubleshooting with 7x24h hotline

- Warranty: 10–15 years (with extended options for registered clients and key accounts)

For detailed technical drawings and calculation support, visit PVC-M water supply pipe product page.

11. Expert FAQ on PVC-M Water Supply Pipe

12. References & Authoritative Citations

- Markets&Markets, “PVC Pipe Market by Application, Material, End-Use – Global Forecast to 2027”

URL: https://www.marketsandmarkets.com/Market-Reports/pvc-pipe-market-11926876.html - ISO 1452:2009 & EN 1452:2009, “Plastic piping systems for water supply and for buried and above-ground drainage and sewerage – Unplasticized (PVC-U) & Modified (PVC-M) polyvinyl chloride”

URL: https://www.iso.org/standard/44017.html - ResearchGate, “Experience in the use of PVC-M pipes in water supply”

URL: https://www.researchgate.net/publication/334563751 - ScienceDirect, “Case Study: Replacement of Old Steel Water Mains with PVC-M – Hydraulic and Economic Impact”

URL: https://www.sciencedirect.com/science/article/pii/S187770581201681X - PlasticPipe Forum: Plastic Pipes Case Studies

- WRAS (Water Regulations Advisory Scheme): https://www.wras.co.uk/

- LIDA Plastic – Product page: PVC-M water supply pipe

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025