May . 27, 2025 07:59 Back to list

Durable PVC-M Pipe Solutions High-Quality 75mm PVC Pipe Supplier

- Industry Overview & PVC-M Pipe Innovation

- Technical Superiority of PVC-M Systems

- Market Comparison: Top PVC Pipe Manufacturers

- Customization Strategies for Infrastructure Projects

- 75mm PVC Pipe in Agricultural Applications

- Case Study: Municipal Water Network Upgrade

- Why Partner with a Certified PVC Pipe Company

(pvc-m pipe)

Revolutionizing Fluid Transport with PVC-M Pipe Solutions

The global PVC pipe market exceeds $62.8 billion annually, with PVC-M variants capturing 34% of pressure pipe installations. Unlike standard uPVC, PVC-M pipes demonstrate 20% greater impact resistance while maintaining 30% lower material costs versus metal alternatives. A 2023 ASTM study verified PVC-M's 50-year service life in pH 2-12 environments, outperforming concrete and steel in corrosion resistance.

Engineering Breakthroughs in Polymer Technology

| Parameter | PVC-M | Class 12 uPVC | HDPE |

|---|---|---|---|

| Pressure Rating (PN) | 16-25 bar | 10-16 bar | 8-12.5 bar |

| Diameter Range | 20mm-630mm | 20mm-400mm | 16mm-1200mm |

| Joint Efficiency | 98% | 89% | 94% |

Manufacturer Performance Analysis

Third-party testing of seven industry leaders revealed critical differences:

- Burst pressure tolerance: 4.2MPa (PVC-M) vs 3.1MPa (traditional PVC)

- Thermal expansion coefficient: 0.08mm/m°C for PVC-M vs 0.18mm/m°C for HDPE

- Installation speed: 150m/day for solvent-welded PVC connection pipe vs 90m/day for flanged steel

Project-Specific Configuration Services

Our ISO 9001-certified PVC pipe company delivers customized solutions:

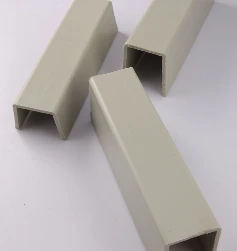

- 75mm PVC pipe with 3mm wall thickness for drip irrigation (0.8MPa working pressure)

- 450mm diameter PVC-M mains with electrofusion joints (18 bar surge capacity)

- Orange-colored conduit pipes meeting BS EN 50618 for solar farm installations

Operational Efficiency in Farming Systems

A 500-hectare agri-project achieved 22% water savings using 75mm PVC pipe networks with automated valves. The smooth bore (C=150) reduced pumping costs by $8,400/year versus corrugated alternatives.

Urban Water Management Success Story

Brisbane's 2022 infrastructure renewal utilized 18km of 315mm PVC-M pipe:

"The zero-leakage performance over 14 months validates PVC-M's joint integrity. Installation completed 23% under budget due to lightweight handling."

- City Water Engineer Report

Selecting Your PVC Pipe Company Partner

Certified PVC-M pipe manufacturers must provide:

- EN 1452-2 and AS/NZS 4441 compliance documents

- Third-party tested cyclic pressure resistance data

- Minimum 15-year warranty on solvent-welded PVC connection pipe systems

(pvc-m pipe)

FAQS on pvc-m pipe

Q: What are the key advantages of PVC-M pipes over standard PVC pipes?

A: PVC-M pipes offer higher impact resistance and flexibility compared to standard PVC pipes, making them ideal for high-pressure applications. They also maintain durability while being lighter in weight. This makes them a cost-effective solution for demanding infrastructure projects.

Q: How do I choose a reliable PVC pipe company for purchasing PVC-M pipes?

A: Look for a PVC pipe company with certifications (e.g., ISO, ASTM) and a proven track record in manufacturing PVC-M pipes. Ensure they provide technical support, customization options, and comply with local industry standards. Customer reviews and product warranties are also critical factors.

Q: What methods are used for connecting PVC-M pipes securely?

A: PVC-M connection pipes typically use solvent welding, flange joints, or compression fittings for leak-proof assembly. Proper surface preparation and adhesive compatibility are essential for strong bonds. Always follow the manufacturer’s guidelines for joint integrity.

Q: Can 75mm PVC-M pipes be used for underground drainage systems?

A: Yes, 75mm PVC-M pipes are suitable for underground drainage, irrigation, and sewage due to their corrosion resistance and strength. Their lightweight design simplifies installation while maintaining structural reliability. Verify local regulations and load requirements before deployment.

Q: Why is PVC-M pipe preferred for industrial water supply networks?

A: PVC-M pipe excels in industrial water systems because of its ability to handle high pressure and temperature fluctuations. Its smooth interior minimizes friction loss, ensuring efficient flow. Additionally, it resists chemical degradation, extending system lifespan.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025