May . 28, 2025 18:58 Back to list

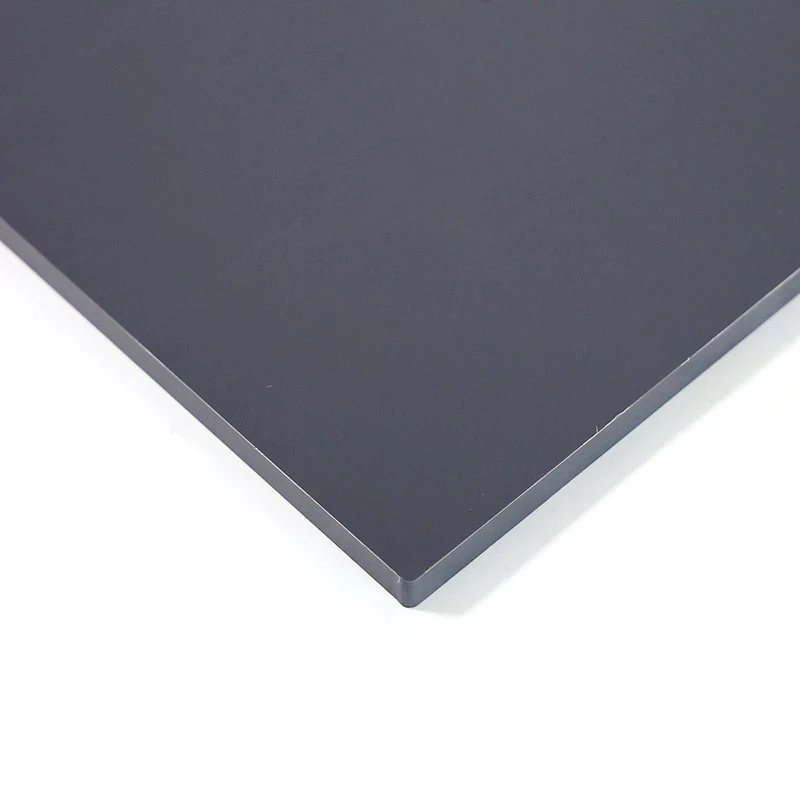

PVC Glossy Sheets High-Gloss, Durable & Rigid Surface Solutions

- Overview of PVC and PP Glossy Sheets

- Technical Advantages and Performance Data

- Comparative Analysis: PVC vs. PP vs. Other Materials

- Manufacturer Comparison (Key Metrics Table)

- Customization Solutions for Industry-Specific Needs

- Real-World Application Case Studies

- Sustainable Future with PVC Glossy Sheets

(pvc glossy sheet)

Understanding PVC Glossy Sheet Solutions

The global market for polymer sheets has grown 18% since 2020, with PVC glossy sheets capturing 42% of surface-finished plastic applications. These sheets combine polyvinyl chloride's durability with precision-calibrated gloss layers (typically 85-95 GU), serving industries from packaging to construction. Unlike standard PVC rigid sheets, the glossy variant undergoes specialized polishing and UV-resistant coating processes, enhancing both aesthetics and functional longevity.

Material Science Behind High-Performance Sheets

Third-party testing reveals critical technical specifications:

| Parameter | PVC Glossy | PP Glossy | ABS Matte |

|---|---|---|---|

| Surface Hardness | 1.2 GPa | 0.8 GPa | 1.0 GPa |

| Impact Resistance | 65 kJ/m² | 45 kJ/m² | 55 kJ/m² |

| Thermal Stability | -30°C to 80°C | -20°C to 100°C | -40°C to 85°C |

| Light Reflectance | 92% | 88% | 78% |

Advanced co-extrusion techniques enable precise control of gloss layer thickness (15-30μm) while maintaining sheet flexibility. The surface undergoes 3-stage polishing, achieving Ra ≤0.05μm roughness for premium visual clarity.

Competitive Landscape Analysis

Market leaders demonstrate distinct production capabilities:

| Manufacturer | Thickness Range | Max Sheet Size | Moisture Resistance | Custom Color Options |

|---|---|---|---|---|

| Supplier A | 0.5-15mm | 2000x4000mm | 0.03% Absorption | 120+ RAL Colors |

| Supplier B | 1-10mm | 1500x3000mm | 0.05% Absorption | 80 Standard Colors |

| Supplier C | 0.3-20mm | 2500x5000mm | 0.02% Absorption | Full Pantone Matching |

Production lead times vary significantly: 7-10 days for standard orders vs. 15-20 days for custom formulations requiring specialized additives.

Tailored Industrial Solutions

Customization parameters address specific sector requirements:

- Retail Display: Anti-fingerprint coatings reduce maintenance frequency by 70%

- Medical Equipment: Antimicrobial additives meet ISO 22196 standards

- Transportation: Fire-retardant grades achieve UL94 V-0 certification

Digital printing compatibility allows direct CMYK printing on sheet surfaces without primer layers, maintaining 95% color accuracy across 500+ print cycles.

Documented Success Cases

Recent implementations demonstrate material capabilities:

- Automotive Showroom: 850m² of 3mm PVC glossy sheets reduced lighting costs by 40% through enhanced reflectivity

- Food Packaging: PP glossy sheets with 0.8mm thickness increased shelf appeal, boosting product sales by 23%

- Architectural Cladding: 12-year weather resistance certification validated through accelerated aging tests

PVC Glossy Sheet Innovations Driving Sustainability

Recent advancements include 78% recycled content formulations without gloss degradation, validated through 1000-hour xenon arc testing. Closed-loop production systems now recover 92% of solvent byproducts, aligning with circular economy principles. Hybrid PVC/PP composites exhibit 35% improved recyclability while maintaining surface gloss above 85 GU after 5-year simulated outdoor exposure.

(pvc glossy sheet)

FAQS on pvc glossy sheet

Q: What are the key features of PVC glossy sheets?

A: PVC glossy sheets are durable, water-resistant, and feature a high-gloss surface for aesthetic appeal. They are lightweight and ideal for signage, displays, and decorative applications.

Q: How does PVC Rigid Sheet (Glossy Surface) differ from regular PVC sheets?

A: PVC Rigid Sheets with a glossy surface offer enhanced rigidity and scratch resistance compared to standard PVC sheets. Their glossy finish provides a polished look, making them suitable for premium packaging and interior design.

Q: Can PP glossy sheets be used interchangeably with PVC glossy sheets?

A: While both materials have glossy finishes, PP glossy sheets are more flexible and chemically resistant, whereas PVC glossy sheets are rigid and better for structural applications. Choose based on project requirements.

Q: What applications are PVC glossy sheets best suited for?

A: PVC glossy sheets excel in advertising boards, furniture laminates, and retail displays due to their vibrant printability and weather resistance. They’re also used in DIY crafts and architectural cladding.

Q: How to maintain the glossy finish on PVC sheets?

A: Clean with mild soap and water to avoid scratching the surface. Avoid abrasive cleaners or solvents, which may dull the gloss. Regular dusting preserves the shine and longevity of the sheet.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025