Sep . 19, 2025 10:30 Back to list

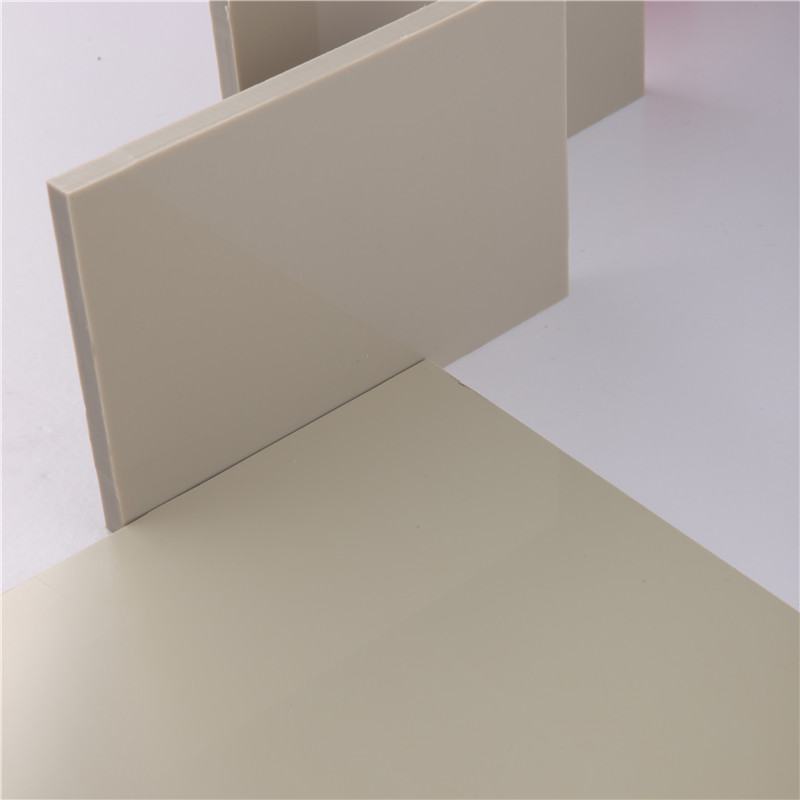

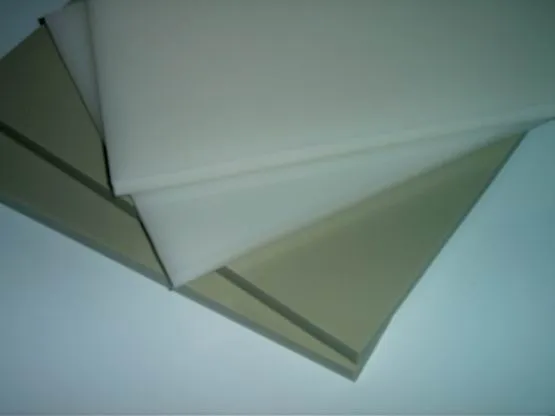

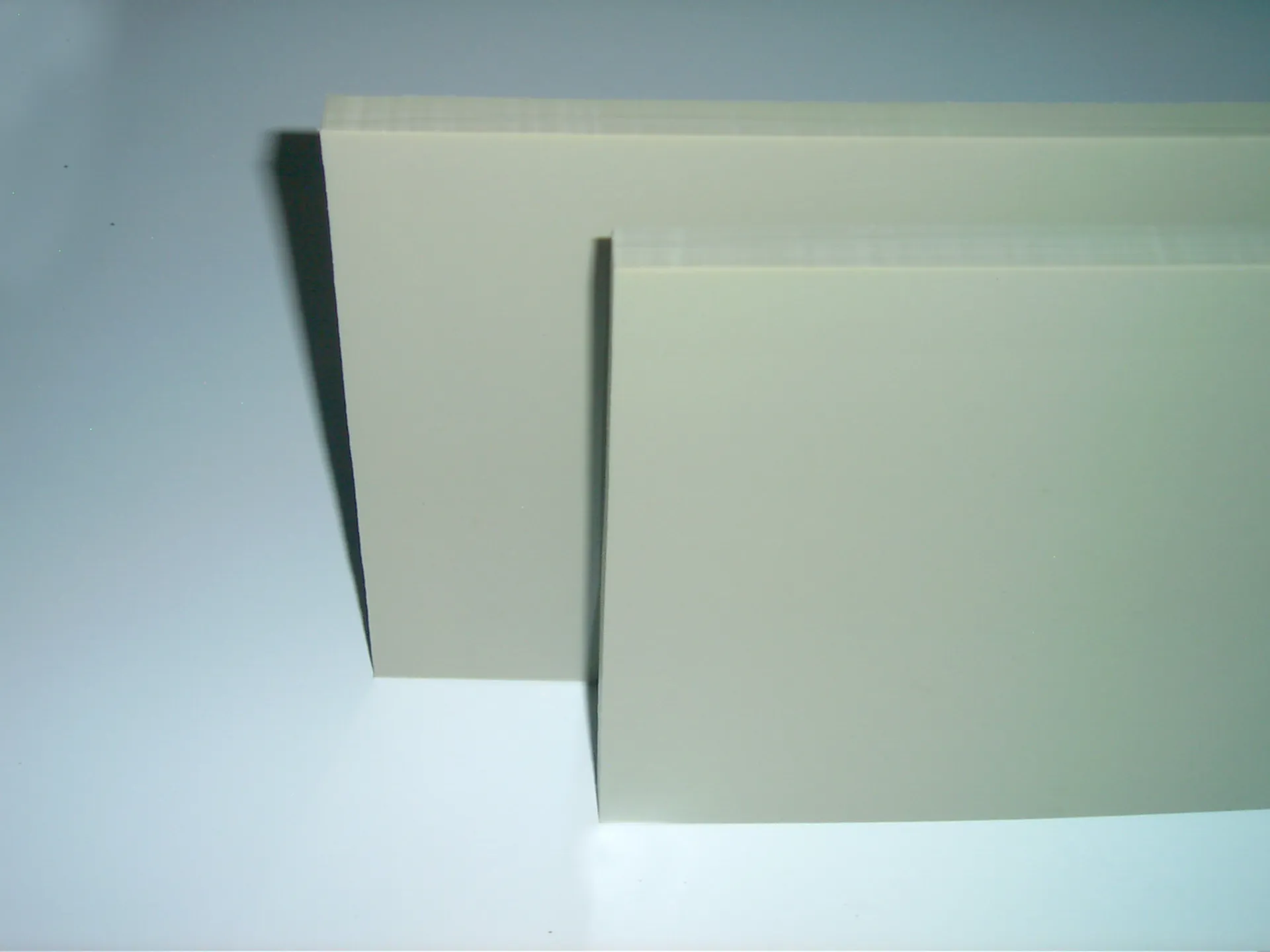

High Performance PPH Sheet | Chemical Resistant Polypropylene Sheets

Industry Trends and the Evolving Role of High-Performance Polymers

In an era marked by stringent environmental regulations and an accelerating demand for materials with superior chemical and thermal resistance, the prominence of high-performance polymers continues to grow across diverse industrial sectors. Among these, PPH sheet stands out as a critical engineering thermoplastic. Its unique combination of properties addresses complex challenges in environments where traditional materials often fail. The market for homopolymer polypropylene materials, specifically PPH, is experiencing robust growth driven by its increasing adoption in petrochemical processing, aggressive chemical storage, advanced water treatment facilities, and precision electronics manufacturing.

Key industry trends underscore this shift: a global emphasis on sustainable infrastructure requiring materials with extended service life, the rapid expansion of semiconductor fabrication demanding ultra-pure and corrosion-resistant components, and the ongoing modernization of industrial facilities aiming for enhanced operational efficiency and safety. These trends collectively amplify the strategic importance of durable, chemically inert, and highly weldable materials like PPH, positioning it as an indispensable solution for future industrial development.

The Precision Manufacturing Process of PPH Sheet

The manufacturing of a high-quality PPH sheet is a sophisticated process that demands meticulous control over material selection, extrusion parameters, and post-processing. This intricate flow ensures the final product meets rigorous industry standards for mechanical strength, chemical resistance, and dimensional stability. The core material is a high-molecular-weight polypropylene homopolymer resin, known for its crystallinity and robust backbone.

Process Flow:

- Raw Material Preparation: High-purity PPH resin granules, often enhanced with specific stabilizers (e.g., UV inhibitors, thermal stabilizers) and processing aids, are precisely weighed and blended. This step is crucial for ensuring the final sheet's long-term service life and performance under specific operational conditions, such as prolonged exposure to sunlight or elevated temperatures.

- Extrusion: The prepared resin blend is fed into a high-performance single or twin-screw extruder. Through precise temperature control across multiple heating zones (typically ranging from 180°C to 230°C), the PPH material is melted and homogenized. The screw design ensures consistent melt flow and prevents degradation, which is vital for maintaining the polymer's integrity.

- Die Forming and Calendering: The molten PPH is then forced through a flat extrusion die, forming a continuous sheet. Immediately following the die, the sheet enters a series of highly polished, temperature-controlled calender rolls. These rolls precisely calibrate the thickness, width, and surface finish (e.g., glossy, matte) of the PPH sheet, ensuring exceptional uniformity and minimal internal stresses.

- Cooling: The formed sheet is progressively cooled, often using water baths or additional chill rolls. Controlled cooling rates are critical to optimize the material's crystalline structure, which directly impacts its mechanical properties, such as tensile strength and impact resistance.

- Trimming and Cutting: Once adequately cooled and solidified, the sheet is trimmed to precise dimensions using automated cutting machinery. This ensures clean edges and adherence to specified length and width tolerances.

- Quality Control and Packaging: Each batch undergoes rigorous quality control, including visual inspection for defects, dimensional measurements, and mechanical property testing (e.g., density, tensile strength, flexural modulus) according to international standards such as ISO 9001 and ASTM D4101. Only sheets meeting stringent parameters are packaged for shipment.

This meticulous manufacturing process ensures that the PPH sheet exhibits superior chemical resistance against a broad spectrum of acids, alkalis, and solvents, coupled with an extended service life often exceeding 50 years in optimal conditions. Target industries such as petrochemicals, metallurgy, and water supply & drainage benefit significantly from these advantages, realizing energy savings through reduced maintenance requirements and enhanced operational safety due to its inherent corrosion resistance.

Technical Specifications and Performance Parameters

Understanding the precise technical specifications of PPH sheet is paramount for engineers and decision-makers in B2B applications. Its homopolymer structure provides a superior balance of stiffness, hardness, and thermal resistance compared to copolymer polypropylene. The material’s high degree of crystallinity contributes directly to its excellent chemical inertness and elevated temperature performance, making it suitable for demanding environments where other plastics might deform or degrade.

The following table outlines typical physical, mechanical, and thermal properties that characterize high-quality PPH sheets. These parameters are crucial for predicting performance in diverse industrial applications and ensuring compliance with project requirements.

Typical PPH Sheet Product Specifications

These specifications highlight the material's suitability for applications requiring rigidity, high operational temperatures, and excellent resistance to chemical attack. Authoritative certifications like ISO 9001 and adherence to ASTM standards confirm the consistency and reliability of manufactured PPH sheets.

Versatile Application Scenarios for PPH Sheet

The exceptional properties of PPH sheet make it a preferred material across a multitude of demanding industrial applications. Its combination of robust chemical resistance, high temperature tolerance, and ease of fabrication allows for reliable performance in critical infrastructure projects. Engineers and procurement specialists frequently specify PPH for projects where long-term durability and resistance to corrosive media are non-negotiable.

Key Application Sectors:

- Chemical Processing & Storage: PPH sheets are extensively used for fabricating chemical storage tanks, reaction vessels, pickling tanks, and linings in environments exposed to strong acids, alkalis, and various organic solvents. Its inertness prevents material degradation and contamination, ensuring safety and product purity.

- Industrial Ventilation & Air Pollution Control: In facilities generating corrosive fumes or aggressive exhaust gases, PPH is ideal for manufacturing ducts, scrubbers, fans, and exhaust hoods. Its resistance to chemical attack maintains the integrity of ventilation systems, crucial for worker safety and environmental compliance.

- Water and Wastewater Treatment: For purification tanks, sedimentation basins, filtration plates, and various components in water treatment plants, PPH offers excellent resistance to both raw and treated water, as well as chemicals used in the treatment process, such as chlorine and ozone.

- Semiconductor & Electronics Manufacturing: The ultra-pure nature and chemical resistance of PPH make it suitable for wet benches, cleanroom furniture, and components for handling high-purity chemicals used in the fabrication of microelectronics.

- Electroplating & Surface Treatment: PPH is employed in the construction of electroplating tanks and equipment due to its ability to withstand the highly aggressive chemical baths involved in surface finishing processes.

Customer feedback consistently highlights the reliability and longevity of PPH installations. For instance, a major chemical producer reported a significant reduction in maintenance costs and increased operational uptime after upgrading their steel storage tanks with PPH linings, citing the material's superior chemical compatibility and durability.

Inherent Technical Advantages of PPH Sheet

The selection of materials in B2B industrial contexts is driven by a critical evaluation of technical advantages that translate into long-term operational efficiency, safety, and cost-effectiveness. PPH sheet offers a compelling suite of benefits that positions it as a superior choice for many demanding applications.

Key Advantages:

- Superior Chemical Resistance: PPH exhibits exceptional resistance to a wider range of corrosive chemicals, including strong inorganic acids, alkalis, and many organic solvents, compared to standard polypropylene copolymers. This makes it indispensable for chemical storage, processing, and effluent treatment systems.

- Enhanced Thermal Performance: With a higher Vicat Softening Point and Heat Deflection Temperature, PPH sheets can operate effectively at elevated temperatures (up to 100°C continuously) without significant deformation or loss of mechanical properties, providing a wider operational window than many other thermoplastics.

- Excellent Weldability and Fabrication Ease: PPH can be readily processed and fabricated using standard thermoplastic welding techniques, including hot gas welding, extrusion welding, and butt fusion. This facilitates the creation of complex, leak-proof structures like tanks, ducts, and custom components with robust joint integrity.

- Long Service Life & Durability: PPH offers superior resistance to environmental stress cracking and UV degradation (when specially formulated), contributing to a significantly extended service life in both indoor and outdoor industrial environments. This reduces the frequency of replacements and associated downtime.

- Lightweight and Cost-Effective: Despite its robust properties, PPH is a relatively lightweight material, simplifying transport, handling, and installation. Its long-term durability and minimal maintenance requirements translate into substantial life-cycle cost savings compared to traditional metallic or less resilient plastic alternatives.

- Environmental Compliance & Safety: As a non-toxic, non-contaminating material, PPH supports environmental sustainability initiatives and enhances safety in applications involving potable water or sensitive chemicals. Its chemical inertness prevents leaching and ensures compliance with strict regulatory standards.

Vendor Comparison and Market Landscape Analysis

Selecting the right supplier for PPH sheet is a critical decision that impacts project timelines, material quality, and overall cost-efficiency. While several manufacturers produce PPH, significant variations can exist in raw material sourcing, manufacturing precision, adherence to international standards, and commitment to customer support. A thorough vendor comparison goes beyond initial pricing, considering factors that ensure long-term performance and reliability.

Authoritativeness is often demonstrated through certifications (e.g., ISO 9001, ISO 14001), consistent quality control protocols, and proven track records with established clients over many years of service. A reputable vendor will provide transparent test data, material safety data sheets (MSDS), and certifications that validate their product's properties.

PPH Sheet Vendor Comparison Matrix

This comparison highlights that while many options exist, a focus on material integrity, manufacturing precision, and comprehensive support, as exemplified by top-tier suppliers, ensures optimal project outcomes and long-term asset protection. Partnering with a manufacturer committed to rigorous quality control and technical expertise minimizes risks and maximizes return on investment.

Customized Solutions and Fabrication Expertise

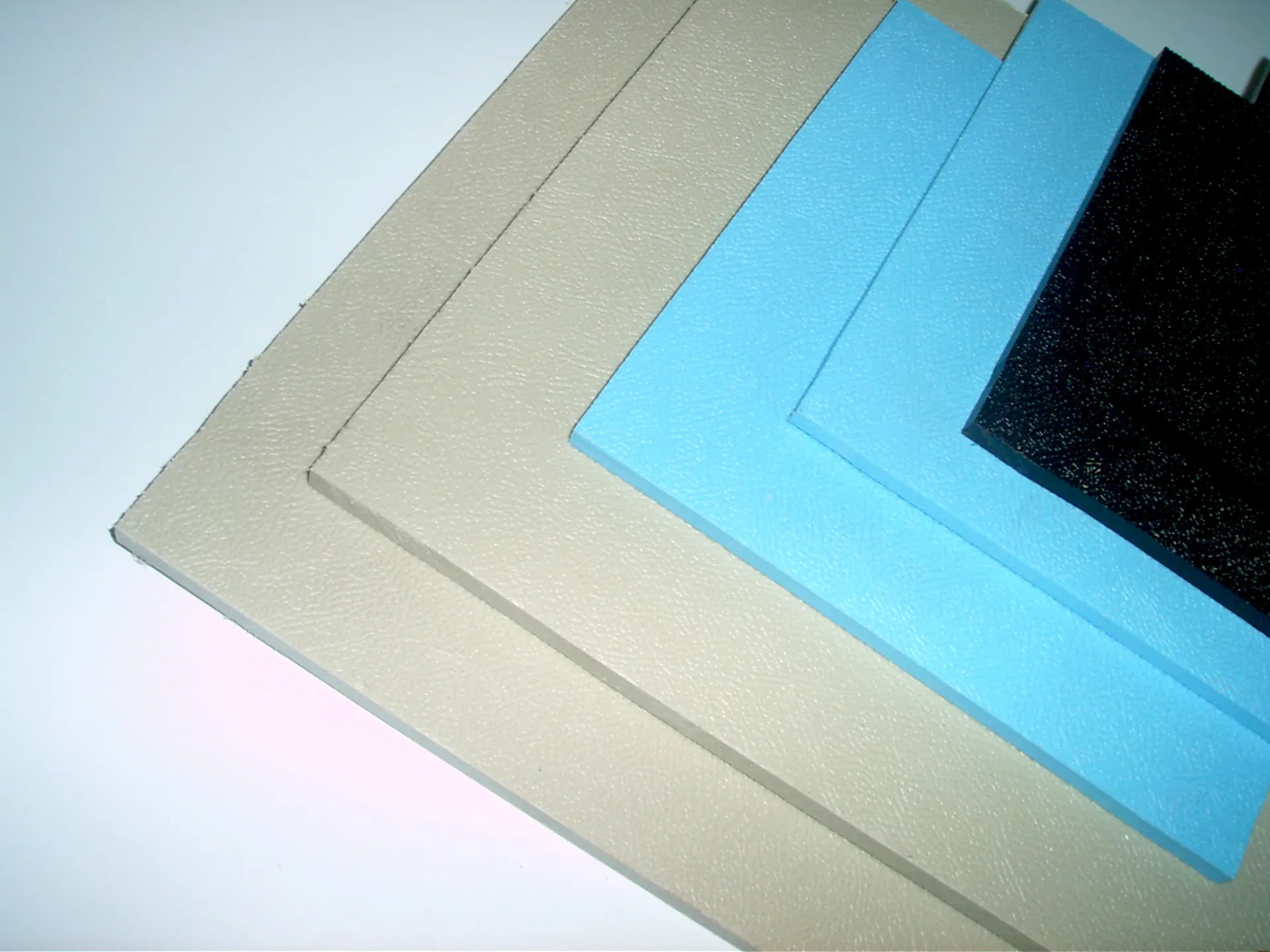

While standard PPH sheet products meet a broad range of industrial requirements, many complex projects necessitate tailor-made solutions. Leading manufacturers offer extensive customization capabilities, allowing engineers to specify precise dimensions, thicknesses, colors, and specialized additive packages to meet unique operational demands. This flexibility is crucial for optimizing performance in highly specific or challenging environments.

Customization Options:

- Dimensions & Thicknesses: Beyond standard sizes, custom widths and lengths can be produced to minimize waste and streamline fabrication processes for large-scale structures like chemical tanks or ventilation systems. Specific thicknesses can be manufactured to withstand particular hydrostatic pressures or mechanical loads.

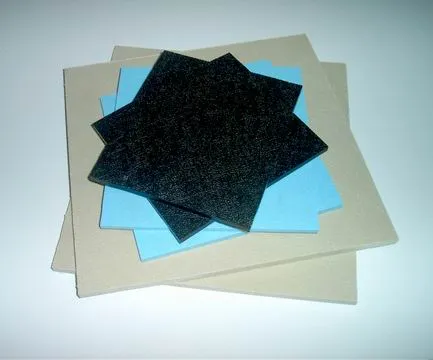

- Color Customization: While natural PPH is translucent or off-white, specific pigments can be incorporated during extrusion to produce sheets in various colors, which can be useful for coding, aesthetic purposes, or meeting branding requirements in certain applications.

- Specialized Additives:

- UV Stabilization: For outdoor applications or environments with high UV exposure, stabilizers can be added to significantly extend the material's lifespan and prevent premature degradation.

- Anti-Static Properties: In sensitive electronics manufacturing or environments where static discharge is a concern, anti-static agents can be incorporated to dissipate static electricity.

- Flame Retardancy: For applications with fire safety requirements, flame-retardant additives can be included, though this may slightly alter other material properties.

Beyond material customization, fabrication expertise is equally vital. Skilled technicians utilize advanced techniques like hot gas welding, extrusion welding, and butt fusion to join PPH sheets into complex, monolithic structures. This ensures the chemical and mechanical integrity of fabricated items, providing seamless and leak-proof solutions for intricate designs such as dual-containment tanks or multi-chamber processing units. Collaboration between the client's engineering team and the manufacturer's fabrication specialists can lead to highly optimized and efficient solutions, maximizing the intrinsic value of PPH.

Real-World Application Case Studies

Demonstrating the practical impact of PPH sheet in industrial settings provides invaluable insights into its capabilities and reliability. These case studies highlight how its technical advantages translate into tangible benefits for businesses facing complex material challenges.

Case Study 1: Large-Scale Chemical Storage Facility Modernization

Client: A leading specialty chemicals manufacturer operating a facility with aging steel storage tanks used for highly corrosive reagents.

Challenge: The existing carbon steel tanks were susceptible to corrosion, leading to frequent maintenance, costly downtime, and potential environmental risks. The client required a durable, chemically inert lining solution that could extend the tanks' lifespan and ensure material purity, without requiring full tank replacement.

Solution: Custom-fabricated PPH sheet liners were designed and installed within the existing steel tanks. The PPH material, known for its superior resistance to concentrated acids and alkalis, was selected for its long-term performance and weldability. Fabrication involved precision cutting and extrusion welding techniques to create a seamless, leak-proof internal lining.

Results: The PPH lining effectively mitigated corrosion issues, significantly extending the service life of the storage tanks. The client reported a 70% reduction in maintenance cycles related to corrosion and eliminated product contamination risks. The enhanced operational safety and reliability contributed to substantial cost savings and improved environmental compliance.

Case Study 2: High-Purity Ventilation System for a Semiconductor Plant

Client: A semiconductor fabrication facility requiring a new exhaust and ventilation system for cleanroom operations, handling corrosive vapor byproducts from etching processes.

Challenge: The existing PVC ductwork showed signs of chemical degradation due to exposure to aggressive etching fumes (e.g., hydrofluoric acid, sulfuric acid vapors), posing a risk to air quality and equipment. A material with superior chemical resistance and excellent fabrication properties for complex ducting was needed.

Solution: An entire ventilation system, including ducts, fume hoods, and scrubber components, was fabricated from PPH sheet. The material's high chemical resistance and thermal stability were perfectly suited for the corrosive and sometimes elevated-temperature exhaust stream. Advanced hot gas welding techniques ensured airtight, robust joints throughout the complex network.

Results: The PPH ventilation system completely eliminated the chemical degradation issues previously experienced. Air quality within the cleanroom improved, and the system maintained its structural integrity under continuous exposure to corrosive media. The client achieved enhanced safety, prolonged equipment life, and compliance with stringent cleanroom air purity standards, demonstrating the superior experience PPH provides in critical applications.

Trustworthiness: FAQ, Lead Time, Warranty & Support

Establishing trustworthiness in the B2B sector requires transparency, clear commitments, and comprehensive support. Understanding these aspects is crucial for decision-makers evaluating suppliers for long-term partnerships involving high-performance materials like PPH sheet.

Frequently Asked Questions (FAQ)

- Q: What is the primary advantage of PPH sheet over standard PP copolymer sheet?

A: PPH (Polypropylene Homopolymer) offers superior stiffness, higher temperature resistance (up to 100°C continuous operating temperature), and generally better chemical resistance, especially to strong acids and alkalis, compared to standard PP (Polypropylene Copolymer) which is more flexible but has lower thermal and chemical performance. - Q: Can PPH sheet be used outdoors?

A: Standard PPH sheet has limited UV resistance. However, specifically formulated UV-stabilized PPH sheets are available for outdoor applications, significantly extending their service life when exposed to sunlight. It's crucial to specify UV stabilization for outdoor use. - Q: What are the typical fabrication methods for PPH sheet?

A: PPH sheet is highly weldable. Common fabrication methods include hot gas welding, extrusion welding, and butt fusion welding. These techniques create strong, leak-proof joints, essential for chemical containment and ventilation systems. - Q: How does PPH sheet contribute to sustainability?

A: PPH contributes to sustainability through its long service life, reducing the need for frequent replacements. It is also a thermoplastic, meaning it can be recycled (though industrial recycling streams for large PPH structures vary by region). Its chemical inertness prevents contamination, supporting environmental safety.

Lead Time & Fulfillment

Standard PPH sheet sizes and thicknesses typically have a lead time of 7-14 business days, depending on current stock levels and order volume. For customized dimensions, colors, or specialized additive packages, lead times may extend to 3-4 weeks to accommodate manufacturing and testing processes. We maintain efficient logistics and supply chain management to ensure on-time delivery and project continuity for our clients. Large volume orders or highly specialized requirements are subject to individual production scheduling and can be discussed directly with our sales team.

Warranty Commitments

We stand behind the quality and performance of our PPH sheets. All products are manufactured under strict ISO 9001 certified quality management systems. We offer a standard 10-year warranty against manufacturing defects in material and workmanship, provided the product is stored, handled, fabricated, and installed according to industry best practices and our technical guidelines. Specific warranty terms for specialized applications or conditions can be outlined in project-specific agreements.

Customer Support Information

Our commitment to our clients extends beyond product delivery. We provide comprehensive technical support, including material selection guidance, fabrication advice, and problem-solving assistance. Our team of experienced engineers is available for consultation to ensure optimal material utilization and project success. For technical inquiries, sales support, or after-sales service, please contact us via our website's contact form, email at sales@lidaplastic.com, or by phone at +86-755-88888888 (example number). We strive to provide timely and effective support to all our B2B partners.

References

- ISO 9001: Quality management systems – Requirements. International Organization for Standardization.

- ASTM D4101: Standard Specification for Propylene Plastic Injection and Extrusion Materials. ASTM International.

- Brandrup, J., & Immergut, E. H. (Eds.). (1999). Polymer Handbook (4th ed.). Wiley-Interscience.

- Rochon, D. (2018). Chemical Resistance of Plastics and Elastomers. Knovel.

-

Comprehensive Guide to HDPE Sewer Pipes: Benefits, Applications & Innovations

NewsNov.25,2025

-

Comprehensive Guide To HDPE Pipes and Fittings | Durable & Sustainable Solutions

NewsNov.24,2025

-

HDPE Culvert Pipe – Durable, Flexible & Sustainable Infrastructure Solutions

NewsNov.24,2025

-

DWC HDPE Pipe – Durable, Cost-Effective Drainage and Conduit Solutions

NewsNov.23,2025

-

HDPE Drainage Pipe – Durable and Sustainable Water Management Solutions

NewsNov.23,2025

-

Durable and Sustainable HDPE Corrugated Pipe Solutions for Modern Infrastructure

NewsNov.23,2025