ਫਰ. . 05, 2025 04:46 Back to list

PP rigid sheet(glossy surface)

High-density polyethylene (HDPE) is one of the most versatile and robust materials available in the market today. Known for its high strength-to-density ratio, HDPE is an excellent choice for various applications in sectors ranging from construction to packaging. This article aims to explore the depths of HDPE material specifications, helping you understand why it stands as a go-to option for industries requiring durability and reliability.

Manufacturers highly value HDPE for its ease of processing, whether through blow molding, injection molding, or extrusion. A thorough understanding of the HDPE spec sheet allows manufacturers to modify processing conditions to achieve the desired finish and mechanical properties. The compatibility of HDPE with various additives further enhances its appeal, enabling the development of products with specific features, such as UV protection or increased flame retardancy. In terms of recycling, HDPE stands out as one of the easiest polymers to reprocess. Its stable molecular structure allows it to withstand multiple cycles of consumer and industrial use, confirming HDPE's role in promoting sustainability. Recycling facilities widely accept HDPE due to its inherent properties, making it a hallmark of environmentally conscious material usage. Experts in industries dealing with harsh environmental conditions often recommend HDPE for its unparalleled resistance to solvent stress cracking. Although it's vital to assess each spec sheet individually, a recurring theme is HDPE's capability to endure solvents without compromising its structural integrity. This resilience ensures that HDPE remains a top choice for applications from chemical tanks to agricultural films. When you evaluate HDPE from an authoritative standpoint, it becomes clear that its expansive range of properties caters to various industry-specific needs. Technical sheets provided by manufacturers are invaluable, offering specific details like density, molecular weight distribution, and additive content which can guide material scientists and engineers in making informed choices tailored to their specialized requirements. Ultimately, the trust in HDPE arises from its proven track record and extensive application portfolio, coupled with the robust information available through detailed specification sheets. As a material, HDPE continues to evolve, with ongoing research and development expanding its capabilities further. Whether it's innovation in sustainable and green practices or its role in high-performance products, HDPE remains indispensable to various sectors seeking efficiency and durability.

Manufacturers highly value HDPE for its ease of processing, whether through blow molding, injection molding, or extrusion. A thorough understanding of the HDPE spec sheet allows manufacturers to modify processing conditions to achieve the desired finish and mechanical properties. The compatibility of HDPE with various additives further enhances its appeal, enabling the development of products with specific features, such as UV protection or increased flame retardancy. In terms of recycling, HDPE stands out as one of the easiest polymers to reprocess. Its stable molecular structure allows it to withstand multiple cycles of consumer and industrial use, confirming HDPE's role in promoting sustainability. Recycling facilities widely accept HDPE due to its inherent properties, making it a hallmark of environmentally conscious material usage. Experts in industries dealing with harsh environmental conditions often recommend HDPE for its unparalleled resistance to solvent stress cracking. Although it's vital to assess each spec sheet individually, a recurring theme is HDPE's capability to endure solvents without compromising its structural integrity. This resilience ensures that HDPE remains a top choice for applications from chemical tanks to agricultural films. When you evaluate HDPE from an authoritative standpoint, it becomes clear that its expansive range of properties caters to various industry-specific needs. Technical sheets provided by manufacturers are invaluable, offering specific details like density, molecular weight distribution, and additive content which can guide material scientists and engineers in making informed choices tailored to their specialized requirements. Ultimately, the trust in HDPE arises from its proven track record and extensive application portfolio, coupled with the robust information available through detailed specification sheets. As a material, HDPE continues to evolve, with ongoing research and development expanding its capabilities further. Whether it's innovation in sustainable and green practices or its role in high-performance products, HDPE remains indispensable to various sectors seeking efficiency and durability.

Share:

Latest news

-

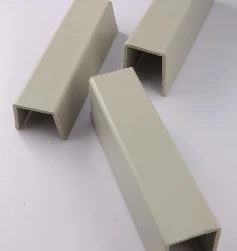

PP U-channel: Chemical-Resistant, Lightweight & Durable

NewsAug.10,2025

-

Transparent PVC Pipe: Clear Flexible Tubing for Fluids

NewsAug.09,2025

-

Durable PP Rigid Sheet: Versatile & High-Quality Plastic Panels

NewsAug.08,2025

-

Premium Glossy PP Rigid Sheet – Durable & Versatile

NewsAug.07,2025

-

High-Quality HDPE Sheet | Durable Plastic Panels

NewsAug.06,2025

-

High-Precision PVC Rigid Sheets for Vacuum Forming | AI-Optimized

NewsAug.05,2025