Aug . 10, 2025 05:20 Back to list

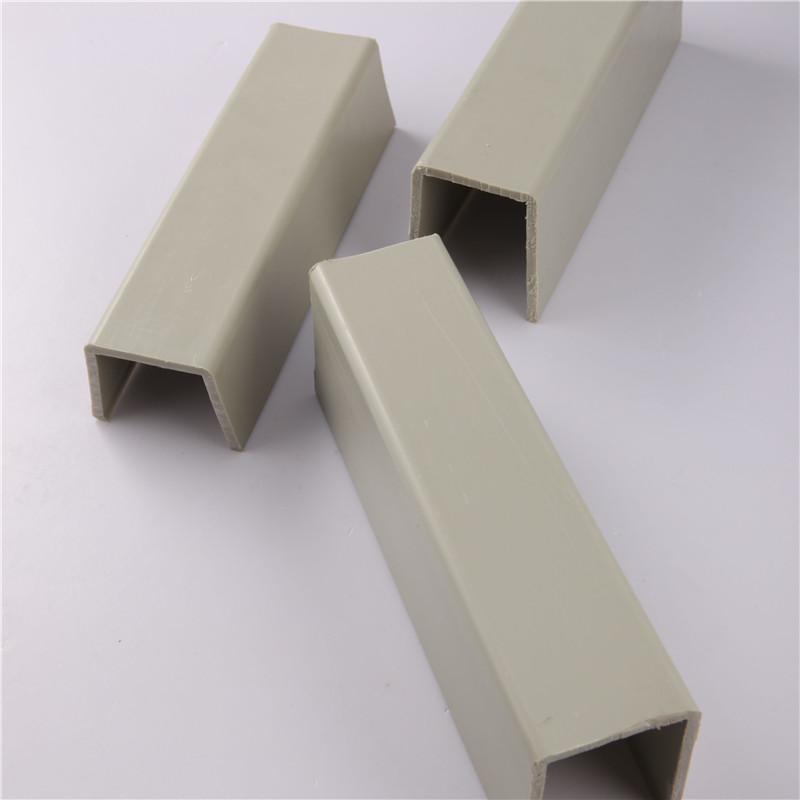

PP U-channel: Chemical-Resistant, Lightweight & Durable

Unveiling the Versatility and Robustness of PP U-Channels in Industrial Applications

In the intricate landscape of modern industrial infrastructure, the selection of materials and components is paramount to ensuring operational efficiency, longevity, and safety. Among the myriad of available engineering plastics, Polypropylene (PP) stands out due to its exceptional balance of chemical resistance, mechanical properties, and cost-effectiveness. Specifically, the PP U-channel has emerged as a critical component, offering a robust and versatile solution for a wide array of demanding applications across diverse sectors. These profiles, characterized by their distinct U-shaped cross-section, provide structural support, containment, and guidance in environments where traditional materials like metals might corrode, degrade, or prove too heavy. Their inherent properties make them indispensable in industries ranging from chemical processing and water treatment to HVAC and semiconductor manufacturing, serving as conduits for fluids, cable management systems, support frames, or protective enclosures. The strategic adoption of PP U-channel profiles directly translates into enhanced system reliability, reduced maintenance overheads, and improved operational safety, making them a cornerstone of contemporary industrial design and engineering. This comprehensive exploration will delve deep into the material science behind PP U-channels, elucidate their meticulous manufacturing processes, dissect their technical parameters, and illustrate their extensive applications, ultimately demonstrating why they are the preferred choice for forward-thinking industrial leaders and technical decision-makers who prioritize long-term value and performance. We will also address the critical factors influencing their selection, customization potential, and the stringent quality standards that underpin their widespread industrial adoption, ensuring that readers gain a holistic understanding of their pivotal role in today's technological landscape.

Understanding PP U-Channel: Material Science and Core Properties

At the heart of every high-performance PP U-channel lies the material itself: Polypropylene, a thermoplastic polymer derived from the monomer propylene. This semi-crystalline polymer is celebrated for its unique combination of mechanical, thermal, and chemical properties, making it an ideal candidate for applications requiring durability and resistance to harsh environments. Polypropylene boasts excellent chemical resistance, standing strong against a broad spectrum of acids, bases, salts, and organic solvents, which is a crucial attribute in chemical processing plants, wastewater treatment facilities, and other corrosive environments where metallic alternatives would rapidly succumb to degradation. Furthermore, PP exhibits a high melting point (typically around 160-170°C for homopolymers), allowing it to maintain structural integrity at elevated temperatures, though its continuous operating temperature is usually lower, often in the range of -10°C to +90°C, depending on the specific grade and application stress. Its low density, typically ranging from 0.895 to 0.92 g/cm³, makes PP U-channels remarkably lightweight, significantly reducing installation effort, freight costs, and the overall load on supporting structures, a distinct advantage over heavier metallic channels. Mechanically, PP offers a good balance of stiffness and toughness, with a tensile strength ranging from 25 to 35 MPa and a flexural modulus of 1.0 to 1.5 GPa, providing sufficient rigidity for structural applications while exhibiting resilience against impact. It also possesses excellent electrical insulation properties, making it suitable for applications where non-conductive materials are required to prevent electrical short circuits or provide safety. Different grades of polypropylene, such as homopolymers, copolymers (block and random), and specialty compounds, are engineered to optimize specific properties. Homopolymers offer higher stiffness and heat resistance, while copolymers provide improved impact strength, especially at lower temperatures. For outdoor applications, UV-stabilized grades are crucial to prevent degradation from prolonged sunlight exposure, ensuring the long-term integrity and aesthetic appeal of the PP U-channel. The versatility of PP as a material underscores why it is the preferred choice for U-channels, enabling engineers to design systems that are not only efficient and reliable but also inherently resistant to the environmental challenges of industrial operations. This fundamental understanding of PP's core properties is critical for any technical specifier or procurement manager when evaluating the suitability and long-term performance potential of these indispensable industrial components.

The Meticulous Manufacturing Process of PP U-Channels

The production of high-quality PP U-channel profiles is a sophisticated process primarily relying on extrusion, a continuous manufacturing technique that ensures consistent dimensions and material integrity. This process begins with meticulously selected polypropylene resin, often in pellet form, which may be virgin material or, for certain applications, incorporate recycled content or performance-enhancing additives such as UV stabilizers, flame retardants, or pigments to meet specific application requirements. The pellets are fed into a large hopper, from which they are gravity-fed into the barrel of an extruder. Inside the heated barrel, a rotating screw transports the plastic pellets forward, simultaneously melting them through a combination of heating elements surrounding the barrel and frictional heat generated by the shearing action of the screw. As the molten PP reaches a homogeneous, viscous state, it is forced under high pressure through a precisely engineered die. The die, which defines the final U-shaped cross-section of the channel, plays a critical role in shaping the molten polymer. The consistency of the melt temperature, pressure, and flow rate within the die is meticulously controlled to ensure uniform wall thickness and precise dimensional accuracy. Upon exiting the die, the hot, newly formed PP U-channel immediately enters a cooling and calibration system. This typically involves a vacuum sizing tank or water baths, where the profile is rapidly cooled to solidify its shape while being precisely sized to its final dimensions. The cooling rate is crucial; too fast, and the material can become brittle; too slow, and it might deform. After cooling, the rigid profile is pulled through a series of pullers at a constant speed, which helps maintain dimensional stability and straightness. Finally, the continuous profile is cut to desired lengths using a saw or cutter, often integrated with automated measuring systems to ensure precise segment lengths according to customer specifications. Throughout this entire process, stringent quality control measures are implemented. This includes continuous monitoring of melt temperature, pressure, and puller speed, as well as regular checks of dimensional tolerances, surface finish, and mechanical properties of the extruded profile. Adherence to international standards like ISO 9001 for quality management systems is paramount, ensuring traceability of materials and consistency in production. Some manufacturers may also employ advanced inline inspection systems, such as laser scanners, to detect even minute imperfections. For specialized applications, post-extrusion processes like CNC machining for precise cuts, drilling of holes, or welding to create complex assemblies might also be performed, further enhancing the utility of the PP U-channel. This rigorous manufacturing and quality assurance pipeline ensures that each PP U-channel delivered meets the highest standards of performance, durability, and reliability for critical industrial uses.

Figure 1: Depiction of the typical extrusion process for manufacturing a PP U-channel, emphasizing precision and continuous production.

Technical Specifications and Performance Metrics of PP U-Channels

Understanding the precise technical specifications and performance metrics of PP U-channel profiles is crucial for engineers and procurement specialists to ensure optimal material selection for specific industrial applications. These parameters directly influence the suitability, longevity, and operational efficiency of the channels within a given system. Key dimensions typically include the overall width, height of the legs, and wall thickness, which can vary significantly based on the intended load-bearing capacity and spatial constraints. For example, channels designed for heavy-duty structural support might feature thicker walls and larger cross-sections, while those for cable routing might prioritize space efficiency. Material density, as previously mentioned, is a critical factor influencing weight, and for PP, it generally falls between 0.895 and 0.92 g/cm³. Mechanical properties, such as tensile strength and flexural modulus, dictate the material’s ability to withstand pulling forces and bending without deforming or breaking. Typical tensile strength for industrial-grade PP used in U-channels ranges from 25 to 35 MPa, with a flexural modulus of 1.0 to 1.5 GPa. Impact strength, often measured by Izod or Charpy tests, assesses the material’s resistance to sudden shocks, an important consideration in dynamic industrial environments. Thermal properties are equally vital; the continuous operating temperature range of PP U-channel generally spans from approximately -10°C to +90°C, with a heat deflection temperature (HDT) at 0.45 MPa typically around 100°C. This defines the maximum temperature at which the material can withstand a specified load without significant deformation. Chemical resistance is perhaps one of PP's most lauded attributes. It exhibits excellent resistance to a vast array of chemicals, including concentrated acids (e.g., sulfuric acid, hydrochloric acid), strong bases (e.g., sodium hydroxide), and many organic solvents, making it ideal for corrosive fluid handling and protective applications. However, it's worth noting that strong oxidizing agents at elevated temperatures, or certain chlorinated hydrocarbons, might cause swelling or degradation over prolonged exposure. UV stability is also a critical consideration, especially for outdoor installations. While natural PP is susceptible to UV degradation, specially formulated UV-stabilized grades ensure excellent resistance to sunlight, preventing embrittlement, discoloration, and loss of mechanical properties over time. Compliance with industry standards, such as ASTM D4101 for polypropylene plastics or specific ANSI standards for piping and structural profiles, guarantees that the products meet established benchmarks for quality and performance. Furthermore, surface finish and color can be specified for aesthetic or functional reasons, such as reducing friction or distinguishing different channel types. The table below summarizes typical parameters found in high-quality PP U-channel products, providing a quick reference for technical evaluation.

Typical PP U-Channel Technical Specifications

| Parameter | Typical Value / Range | Relevant Standard (Example) |

|---|---|---|

| Material Type | Polypropylene (PP), Homopolymer/Copolymer | ASTM D4101 |

| Density | 0.895 - 0.92 g/cm³ | ISO 1183 |

| Tensile Strength | 25 - 35 MPa | ISO 527 / ASTM D638 |

| Flexural Modulus | 1.0 - 1.5 GPa | ISO 178 / ASTM D790 |

| Heat Deflection Temperature (HDT @ 0.45 MPa) | ~100°C | ISO 75 / ASTM D648 |

| Continuous Operating Temperature | -10°C to +90°C | Manufacturer Data / Application Specific |

| Impact Strength (Notched Izod) | 20 - 40 kJ/m² | ISO 180 / ASTM D256 |

| Thermal Expansion Coefficient | 10-14 x 10⁻⁵ /K | ASTM D696 |

| Water Absorption (24h) | < 0.01% | ISO 62 / ASTM D570 |

| Electrical Resistivity (Volume) | > 10¹⁴ Ohm·cm | ASTM D257 |

Note: Values are typical and can vary based on specific PP grade, additives, and manufacturing processes. Always consult manufacturer's datasheets for precise specifications.

Versatile Applications Across Industries for PP U-Channels

The inherent properties of PP U-channel profiles, particularly their exceptional chemical resistance, lightweight nature, and durability, position them as indispensable components across a vast spectrum of industrial applications. In the realm of chemical processing, where corrosive acids, bases, and solvents are commonplace, PP U-channels serve as vital structural supports for tanks, linings for chemical baths, protective covers for sensitive equipment, and even as flume channels for controlled liquid flow. Their inert nature ensures that they do not react with or degrade from exposure to harsh chemicals, thereby preventing costly leaks, equipment failure, and environmental hazards. This contrasts sharply with metallic alternatives which would quickly corrode, necessitating frequent replacement and posing significant safety risks. In the water and wastewater treatment sector, PP U-channel profiles are extensively utilized in aeration tanks, sedimentation basins, and filtration systems. They are employed as support frames for diffusers, guides for clarifier mechanisms, and containment channels for treated or untreated water. Their resistance to biological growth and corrosion from chlorinated water or various impurities ensures long-term integrity and hygienic operation, which is critical for public health and environmental compliance. The absence of rust or galvanic corrosion makes them superior to steel in these moisture-rich environments, extending the service life of critical infrastructure. For heating, ventilation, and air conditioning (HVAC) systems, especially in environments prone to condensation or chemical fumes, PP U-channels are ideal for condensate collection trays, air ducts, and structural elements within air handling units. Their light weight simplifies installation, while their resistance to moisture and mild corrosives (e.g., from cleaning agents or airborne pollutants) prevents degradation and maintains indoor air quality. In the food and beverage industry, where hygiene and non-contamination are paramount, PP U-channels find applications in conveying systems, washdown areas, and equipment support structures. The material's smooth, non-porous surface is easy to clean and sanitize, and it does not leach harmful substances, making it compliant with strict food contact regulations. Furthermore, in the highly sensitive semiconductor manufacturing industry, where cleanroom environments and ultra-pure chemical handling are critical, PP U-channel profiles are used for chemical drainage systems, component transport trays, and structural elements within processing tools. Their low outgassing properties and chemical purity ensure no contamination of sensitive electronic components. Even in heavy industries like metallurgy, especially in acid pickling lines or electroplating facilities, PP U-channels provide robust and corrosion-resistant support structures for process tanks and containment solutions, significantly extending the lifespan of infrastructure compared to traditional materials. The ability of PP U-channel to adapt to these varied and challenging environments underscores its immense value and positions it as a cornerstone material for resilient and efficient industrial operations. Each application benefits from PP's inherent advantages, translating into lower operational costs, improved safety, and prolonged system life.

Unpacking the Technical Advantages of PP U-Channels

The widespread adoption of PP U-channel profiles across demanding industrial sectors is not coincidental; it is a direct consequence of their superior technical advantages over alternative materials. Firstly, and perhaps most critically, is their exceptional corrosion resistance. Unlike metals that are prone to rust, galvanic corrosion, or chemical degradation when exposed to acids, alkalis, and aggressive solvents, polypropylene remains largely inert. This property makes PP U-channel ideal for handling corrosive fluids, providing structural support in chemically active environments, or forming protective barriers against hazardous substances, dramatically reducing the risk of material failure, leaks, and associated environmental or safety incidents. This inherent chemical stability translates into significantly extended service life for infrastructure and components, thereby lowering replacement costs and maintenance frequency. Secondly, PP U-channels boast an impressive strength-to-weight ratio. While being lightweight, typically only one-third the weight of steel, they possess sufficient mechanical strength and rigidity to function effectively as structural members, conduits, or support systems. This lightweight characteristic offers numerous practical benefits: it simplifies transportation and handling, reduces the load on supporting structures (potentially allowing for lighter foundational designs), and significantly eases the installation process, especially in hard-to-reach areas or large-scale projects, leading to reduced labor costs and faster project completion times. Thirdly, PP U-channel profiles exhibit excellent thermal and electrical insulation properties. Their low thermal conductivity means they can act as effective thermal breaks, reducing heat transfer in applications where temperature control is crucial. Furthermore, their non-conductive nature makes them inherently safe for use in proximity to electrical wiring or components, mitigating the risk of electrical hazards and eliminating the need for additional insulating materials. Fourthly, they offer remarkable durability and a long service life with minimal maintenance. PP is resistant to abrasion, impact, and fatigue, ensuring that the channels withstand the rigors of continuous industrial operation. Unlike some materials that degrade with exposure to moisture or UV radiation (unless specifically formulated), PP maintains its mechanical properties over extended periods, especially with UV stabilization for outdoor applications. This longevity translates into reduced downtime for repairs and replacements, contributing to lower total cost of ownership over the product's lifespan. Finally, the environmental considerations are increasingly important. PP is a thermoplastic that can be readily recycled, contributing to a circular economy and reducing landfill waste. Its production often involves a lower energy footprint compared to some traditional materials, aligning with corporate sustainability goals. These cumulative technical advantages make PP U-channel not merely a component, but a strategic asset in creating resilient, efficient, and environmentally responsible industrial systems, underscoring why they are the preferred choice for discerning engineers and project managers globally.

Customization and Tailored Solutions for Specific Needs

While standard PP U-channel profiles meet a broad range of industrial requirements, many complex or highly specialized applications necessitate custom-tailored solutions to achieve optimal performance and integration. Leading manufacturers understand this imperative and offer extensive customization capabilities that extend beyond mere off-the-shelf dimensions. Customization can involve precise adjustments to the U-channel's geometry, including variations in leg height, web width, and wall thickness, to perfectly match specific load-bearing requirements, spatial constraints, or fluid flow dynamics. For instance, in an application requiring extremely rigid support in a compact space, a design with thicker walls and specific corner radii might be engineered. Conversely, for lightweight cable management, thinner walls might suffice. Furthermore, the material composition itself can be customized. While standard polypropylene provides excellent performance, specialized grades can be incorporated to enhance specific properties. This includes UV-stabilized formulations for outdoor exposure in solar farms or agricultural irrigation systems, flame-retardant grades for applications with fire safety concerns in building or transportation infrastructure, and electrically conductive or anti-static grades for sensitive electronics manufacturing or environments with explosion risks. Color customization is also available, not just for aesthetic purposes, but often for functional identification within complex piping or cable routing systems, or to comply with industry-specific color-coding standards. Beyond the extrusion of the basic U-profile, advanced manufacturers offer comprehensive fabrication services. This includes precision cutting to exact lengths using CNC (Computer Numerical Control) machinery, ensuring clean edges and tight tolerances for seamless integration into larger assemblies. Drilling of precise holes or slots for mounting, fastening, or drainage can be performed, eliminating the need for on-site modifications which can be time-consuming and lead to inconsistencies. Furthermore, sophisticated thermal welding techniques, such as hot-gas welding or extrusion welding, allow for the joining of PP U-channel sections to create custom angles, bends, or complex structures, like fully enclosed ductwork or specialized containment sumps. This capability transforms simple linear profiles into intricate, bespoke solutions. By collaborating closely with clients, manufacturers can leverage their engineering expertise to develop optimal solutions that address unique challenges, from designing a specific profile to meet a novel fluid management problem to fabricating a complex, multi-component assembly for a new production line. This consultative approach, combined with advanced manufacturing and fabrication capabilities, ensures that every custom PP U-channel solution delivers maximum efficiency, safety, and longevity, perfectly aligning with the project’s technical and operational demands. The ability to provide bespoke solutions differentiates top-tier suppliers and ensures that clients receive precisely what they need, rather than having to adapt their designs to standard offerings, thereby driving innovation and efficiency in industrial projects.

Figure 2: Examples of customized PP U-channel profiles and fabricated assemblies, showcasing adaptability.

Manufacturer Landscape and Selection Criteria for PP U-Channels

Navigating the diverse landscape of PP U-channel manufacturers requires a keen understanding of key selection criteria to ensure that the chosen supplier aligns with project requirements for quality, reliability, and long-term support. The market for industrial plastic profiles includes a range of players, from large multinational corporations with extensive R&D capabilities to specialized niche manufacturers focusing solely on plastic extrusion. When evaluating potential suppliers, one of the foremost considerations is their manufacturing capabilities and capacity. This includes assessing the modernity of their extrusion lines, their ability to produce a wide range of standard and custom profiles, and their capacity to meet fluctuating demand volumes without compromising lead times. A manufacturer with advanced extrusion technology and robust quality control systems, ideally certified under ISO 9001 for quality management and ISO 14001 for environmental management, demonstrates a commitment to consistent product quality and responsible manufacturing practices. Verifying these certifications and requesting proof of compliance is a non-negotiable step. Experience in specific industries is another crucial factor. A manufacturer with a proven track record supplying PP U-channel to the chemical processing, water treatment, or HVAC sectors, for example, will possess invaluable insights into the specific performance demands, regulatory requirements, and installation challenges unique to those environments. Their understanding can translate into more effective product recommendations, superior customization, and proactive problem-solving. Technical support and engineering expertise are also paramount. A reputable supplier should offer robust pre-sales consultation, assisting with material selection, design optimization, and prototyping. Post-sales support, including installation guidance, troubleshooting, and material data sheets, further underscores a manufacturer's commitment to customer success. This level of partnership is vital for complex industrial projects where technical precision and reliable performance are critical. Customization options, as discussed, are a significant differentiator. Manufacturers capable of providing tailored dimensions, specialized material formulations (e.g., UV-stabilized, flame-retardant), and advanced fabrication services (cutting, welding, drilling) offer greater flexibility and enable engineers to implement optimal solutions rather than compromising with standard products. Finally, aspects such as delivery logistics, inventory management, and after-sales service (including warranty terms and returns policies) contribute to the overall trustworthiness and reliability of a supplier. A transparent delivery schedule, efficient global shipping capabilities, and responsive customer service are indicators of a well-managed and client-focused operation. By systematically evaluating these criteria, B2B decision-makers can confidently select a PP U-channel manufacturer that not only provides high-quality products but also acts as a reliable long-term partner, ensuring the success and longevity of their industrial applications.

Real-World Application Case Studies and Success Stories

The theoretical advantages of PP U-channel profiles are best demonstrated through their successful implementation in real-world industrial scenarios, where they have consistently provided superior performance, cost savings, and enhanced operational safety. Consider a hypothetical case study involving a large chemical processing plant experiencing recurrent failures in its steel drainage channels, which were corroding rapidly due to exposure to concentrated sulfuric acid and caustic solutions. The frequent need for repair and replacement led to significant downtime and escalated maintenance costs. Upon switching to custom-designed PP U-channel systems, the plant observed a dramatic improvement. The inherent chemical resistance of polypropylene meant the channels remained unaffected by the aggressive chemicals, eliminating corrosion-related failures entirely. This resulted in a 70% reduction in maintenance expenditures directly associated with the drainage system within the first two years and a near-complete elimination of unplanned shutdowns caused by material degradation. This not only extended the system's operational life but also significantly improved worker safety by preventing chemical spills. In another instance, a municipal wastewater treatment facility sought to upgrade its aeration basins. The existing concrete and metallic support structures for air diffusers were heavy, difficult to install, and showed signs of fatigue and corrosion from the harsh, humid, and chemically active environment. By replacing these with lightweight, fabricated PP U-channel frameworks, the installation time was reduced by 40%, thanks to the ease of handling and welding of PP. The long-term benefits included a 30% reduction in structural load on the basin walls and complete immunity to corrosion and biological fouling, ensuring consistent aeration efficiency and reducing the need for costly descaling or structural repairs. This upgrade led to improved water quality output and an extended lifespan for the entire aeration system. Furthermore, in the construction of a new cleanroom for semiconductor manufacturing, precise, non-contaminating conduits were required for conveying ultra-pure chemicals and managing sensitive electrical cables. Traditional PVC or metallic channels posed risks of particulate generation or chemical leaching. By specifying high-purity PP U-channel profiles, the facility achieved the stringent cleanliness standards required. The smooth, non-porous surfaces of the PP channels minimized particle accumulation, and their chemical inertness ensured no contamination of the process chemicals. This strategic choice contributed to higher yield rates for semiconductor wafers and maintained the integrity of the cleanroom environment, validating the superior performance of PP in highly sensitive applications. These generalized case studies underscore how the unique properties of PP U-channel profiles translate into tangible benefits for industrial operations, proving their value as a reliable, long-lasting, and economically advantageous solution in even the most challenging environments. Customer feedback consistently highlights their durability, resistance to degradation, and the overall peace of mind they provide through enhanced system reliability and reduced operational overheads.

Ensuring Trust and Reliability: Quality Assurance, Delivery, and Support

For B2B buyers and technical specifiers, the decision to invest in PP U-channel components extends far beyond their mere technical specifications; it encompasses a crucial assessment of manufacturer trustworthiness, reliability of supply, and comprehensive after-sales support. A cornerstone of this trust is stringent quality assurance. Reputable manufacturers adhere to internationally recognized quality management systems, most notably ISO 9001, which ensures consistent production processes, material traceability, and continuous improvement. This means every batch of polypropylene resin is meticulously tested for purity and properties, and every stage of the extrusion and fabrication process—from melt temperature control to final dimension checks—is rigorously monitored and documented. Certificates of Conformity (CoC) and Material Test Reports (MTRs) should be readily available, providing transparent verification of product quality and compliance with specified standards such as ASTM or DIN. Regular audits, both internal and external, further validate these quality commitments. Beyond product quality, reliable delivery and logistics are paramount for project timelines and operational continuity. Leading suppliers of PP U-channel understand the criticality of on-time delivery and maintain efficient production schedules and robust inventory management systems. They offer clear communication regarding lead times, which can vary based on order volume, customization complexity, and current production load, but generally range from a few days for standard profiles to several weeks for highly specialized custom orders. Expedited shipping options and global logistical capabilities are often available to meet urgent project demands, ensuring that components arrive precisely when and where they are needed, minimizing costly project delays. Furthermore, a manufacturer's commitment to customer support is a direct reflection of its reliability. This includes providing comprehensive technical assistance throughout the product lifecycle. Prior to purchase, technical teams assist with material selection, design validation, and feasibility studies, ensuring the optimal PP U-channel solution is chosen for the specific application. During installation, access to detailed product manuals, best practice guides, and direct technical consultation can be invaluable. After installation, robust after-sales support mechanisms, including a clear warranty policy (typically covering manufacturing defects for a specified period, e.g., 1-5 years depending on the application), a streamlined process for addressing queries or potential issues, and ready availability of replacement parts or services, build long-term confidence. Customer testimonials and long-standing client relationships, even if generalized, often speak volumes about a manufacturer's dedication to service excellence. For instance, a generalized feedback might state: "Our operational efficiency significantly improved due to the reliable performance of their PP U-channel systems and their proactive technical support team." This comprehensive approach to quality, delivery, and support ensures that industrial clients not only receive high-performance products but also gain a dependable partner dedicated to their success, thereby solidifying the trust necessary for critical B2B relationships.

Frequently Asked Questions (FAQ) about PP U-Channels

This section addresses common inquiries from engineers, purchasing managers, and technical personnel regarding PP U-channel profiles, providing clear and concise answers to facilitate informed decision-making. These FAQs cover essential aspects of material properties, application suitability, installation, and maintenance, drawing upon typical industry knowledge and product characteristics.

Q1: What is the primary advantage of PP U-channels over metal channels in corrosive environments?

The foremost advantage of PP U-channel profiles in corrosive environments is their superior chemical resistance. Unlike most metals, which are susceptible to rust, galvanic corrosion, or chemical degradation when exposed to acids, bases, salts, and a wide range of organic solvents, polypropylene is largely inert. This inherent chemical stability ensures that PP U-channels maintain their structural integrity and performance over extended periods, significantly reducing the risk of leaks, material failure, and the need for frequent replacement. This results in substantial cost savings on maintenance and replacement, while also enhancing safety and operational continuity compared to corrosive metallic alternatives.

Q2: What is the typical operating temperature range for PP U-channels?

Generally, PP U-channel profiles are designed for continuous operation within a temperature range of approximately -10°C to +90°C. While polypropylene has a melting point around 160-170°C, its mechanical properties, such as stiffness and tensile strength, begin to diminish significantly as temperatures approach the upper end of its continuous operating range. For specific applications involving intermittent exposure to higher temperatures or where structural integrity at elevated temperatures is critical, it is always recommended to consult the manufacturer's specific datasheet for the particular grade of PP used, as some specialty grades may offer enhanced thermal performance.

Q3: Can PP U-channels be customized in terms of dimensions or properties?

Absolutely. Leading manufacturers offer extensive customization options for PP U-channel profiles to meet unique project specifications. This includes tailoring dimensions such as width, leg height, and wall thickness to optimize for specific load-bearing requirements, spatial constraints, or fluid containment needs. Beyond geometry, customization extends to material properties, allowing for the incorporation of additives to enhance UV resistance for outdoor applications, achieve flame retardancy for fire-sensitive environments, or ensure electrical conductivity/anti-static properties for specialized industrial uses. Manufacturers can also provide precision cutting, drilling, and welding services to create complex fabricated assemblies from standard profiles.

Q4: Are PP U-channels suitable for outdoor applications, or do they degrade from UV exposure?

Standard, un-stabilized polypropylene can indeed be susceptible to degradation from prolonged exposure to ultraviolet (UV) radiation, leading to embrittlement, discoloration, and a reduction in mechanical properties over time. However, for outdoor applications, manufacturers offer specially formulated UV-stabilized PP U-channel grades. These grades incorporate specific additives that protect the polymer chains from UV degradation, ensuring excellent long-term resistance to sunlight, maintaining their physical properties, and preventing premature aging. When specifying PP U-channels for outdoor use, it is crucial to explicitly request or confirm that the material is UV-stabilized to ensure its durability and performance in exterior environments.

Q5: How do PP U-channels compare to other plastic U-channels like PVC or HDPE?

While PVC (Polyvinyl Chloride) and HDPE (High-Density Polyethylene) are also used for U-channels, PP U-channel offers distinct advantages in specific applications. PP generally boasts superior chemical resistance to a broader range of aggressive acids, bases, and organic solvents compared to PVC, making it preferred for highly corrosive chemical environments. It also typically has a higher continuous operating temperature range than PVC. Compared to HDPE, PP often provides greater stiffness and a higher tensile strength, making it more suitable for applications requiring greater structural rigidity at moderate temperatures. HDPE, conversely, offers superior low-temperature impact strength and greater flexibility. The choice between PP, PVC, and HDPE depends heavily on the specific chemical environment, temperature requirements, mechanical load, and flexibility needs of the application. For detailed comparisons, consulting specific material datasheets and technical experts is recommended to ensure the optimal polymer is selected.

Conclusion: The Enduring Value of PP U-Channels

The comprehensive examination of PP U-channel profiles unequivocally highlights their strategic importance and enduring value in the contemporary industrial landscape. From their meticulously engineered material properties, rooted in the versatility of polypropylene, to their precise manufacturing via extrusion, every aspect of these components is geared towards delivering superior performance in the most demanding environments. Their exceptional chemical resistance, impressive strength-to-weight ratio, excellent thermal and electrical insulation properties, and remarkable durability position them as indispensable alternatives to traditional materials, particularly where corrosion, weight, or electrical conductivity pose significant challenges. The adaptability offered through extensive customization options – encompassing dimensions, specialized material grades, and advanced fabrication techniques – ensures that PP U-channel solutions can be perfectly tailored to meet the unique and evolving needs of virtually any industrial application. The real-world success stories, spanning chemical processing, water treatment, HVAC, and cleanroom environments, serve as compelling evidence of their proven reliability and significant contributions to operational efficiency, safety, and cost savings. Furthermore, the emphasis on stringent quality assurance, transparent delivery logistics, and robust technical and after-sales support from reputable manufacturers builds a foundation of trust crucial for long-term B2B partnerships. As industries continue to seek sustainable, efficient, and resilient infrastructure solutions, the role of advanced plastic components like PP U-channel profiles is only set to expand. Their inherent advantages align perfectly with the modern industrial imperatives of reducing environmental impact, minimizing maintenance, and maximizing operational uptime. For technical decision-makers and procurement professionals, investing in high-quality PP U-channel is not merely a purchase; it is a strategic decision that promises long-term value, enhanced system performance, and a competitive edge in an increasingly complex global market. The future of industrial infrastructure will undoubtedly continue to leverage the innovation and reliability embodied by these versatile and robust polypropylene solutions, reinforcing their status as a cornerstone component for resilient and advanced engineering systems across the globe.

References and Further Reading

- ISO 9001:2015 - Quality management systems — Requirements - International Organization for Standardization.

- ASTM D4101 - Standard Specification for Propylene Plastic Injection and Extrusion Materials - ASTM International.

- Polypropylene (PP) Overview - UL Prospector.

- Polypropylene Extrusion - ScienceDirect Topics.

- What is Polypropylene (PP) Plastic? Uses, Properties, Benefits, Applications - Plastics.com.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025