Feb . 13, 2025 18:16 Back to list

HDPE reinforced spiral corrugated pipe with steel belt

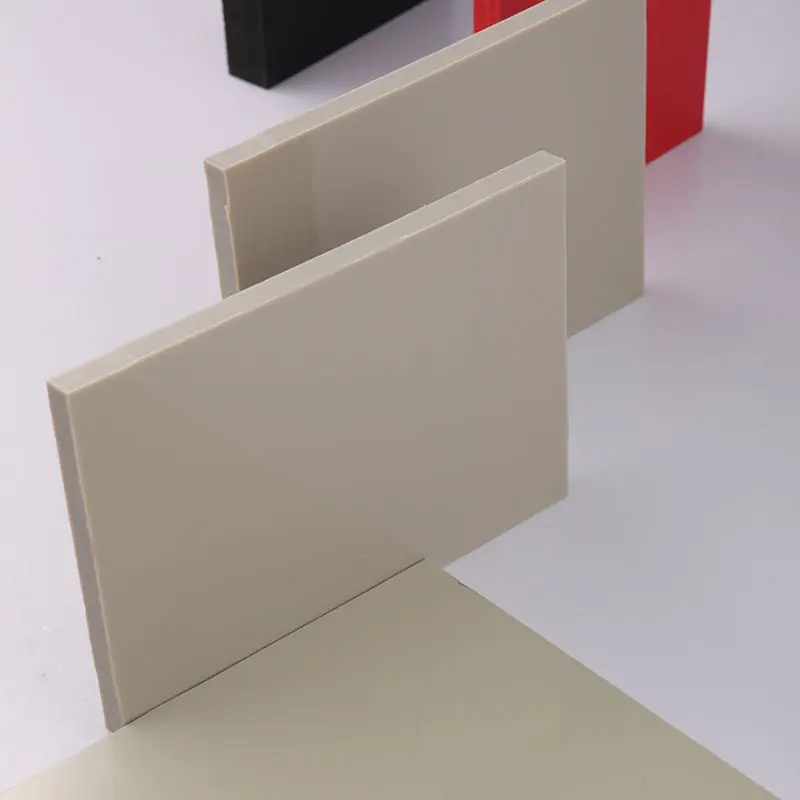

Polyethylene sheets, often referred to as PE sheets, have become integral in various industries due to their versatile applications, durability, and cost-effectiveness. As a material, polyethylene is renowned for its robustness, flexibility, and resistance to chemicals and moisture, making it indispensable in fields ranging from packaging to construction. This article explores some critical aspects of PE sheets, shedding light on their real-world applications, expert opinions on their benefits, and the authoritative voices that vouch for their reliability, aiming to provide you with a comprehensive understanding rooted in experience, expertise, authoritativeness, and trustworthiness.

Handling and installation of PE sheets are straightforward, allowing for ease of use across various applications. The sheet's inherent flexibility ensures that they conform to different surfaces and shapes without compromising their structural integrity. Industry practitioners often discuss best practices and expert tips on optimizing the use of PE sheets – from choosing the correct thickness for a specific application to effective installation techniques that maximize their lifespan and efficiency. In educational settings and technical workshops, PE sheets serve as prime examples of material that balances performance with practicality. Courses and seminars frequently include discussions about PE sheets as a case study in polymer technology, offering attendees real-world scenarios and expert testimonials on their efficacy and practicality. By educating upcoming professionals, these learning platforms solidify the authoritative standing of PE sheets as an essential material in both traditional and novel applications. Safety considerations also play a crucial role in the widespread adoption of PE sheets. Known for being non-toxic and chemically inert, these sheets provide peace of mind in industries where safety is paramount. Trustworthiness in terms of product safety is built upon rigorous testing and certification processes, ensuring PE sheets meet international safety standards. Parents, manufacturers, and construction foremen alike appreciate this aspect, knowing that PE sheets pose minimal risk to both human health and the environment. As industries evolve and demands shift, PE sheets continue to be at the forefront, adapted by experts in material science and technology to meet the challenges of tomorrow. Their sustained relevance across various sectors is a testament to the trust and authority they command. Through continual research, innovation, and sustainable practices, polyethylene sheets maintain their status as a reliable, expert-endorsed solution dedicated to enhancing efficiency and efficacy in myriad applications.

Handling and installation of PE sheets are straightforward, allowing for ease of use across various applications. The sheet's inherent flexibility ensures that they conform to different surfaces and shapes without compromising their structural integrity. Industry practitioners often discuss best practices and expert tips on optimizing the use of PE sheets – from choosing the correct thickness for a specific application to effective installation techniques that maximize their lifespan and efficiency. In educational settings and technical workshops, PE sheets serve as prime examples of material that balances performance with practicality. Courses and seminars frequently include discussions about PE sheets as a case study in polymer technology, offering attendees real-world scenarios and expert testimonials on their efficacy and practicality. By educating upcoming professionals, these learning platforms solidify the authoritative standing of PE sheets as an essential material in both traditional and novel applications. Safety considerations also play a crucial role in the widespread adoption of PE sheets. Known for being non-toxic and chemically inert, these sheets provide peace of mind in industries where safety is paramount. Trustworthiness in terms of product safety is built upon rigorous testing and certification processes, ensuring PE sheets meet international safety standards. Parents, manufacturers, and construction foremen alike appreciate this aspect, knowing that PE sheets pose minimal risk to both human health and the environment. As industries evolve and demands shift, PE sheets continue to be at the forefront, adapted by experts in material science and technology to meet the challenges of tomorrow. Their sustained relevance across various sectors is a testament to the trust and authority they command. Through continual research, innovation, and sustainable practices, polyethylene sheets maintain their status as a reliable, expert-endorsed solution dedicated to enhancing efficiency and efficacy in myriad applications.

Share:

Latest news

-

High-Precision PVC Rigid Sheets for Vacuum Forming | AI-Optimized

NewsAug.05,2025

-

Durable PVC-M Water Supply Pipes | 60-Year Life

NewsAug.04,2025

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025

-

HDPE Drainage & Irrigation Pipe - Durable, Efficient Solutions

NewsAug.01,2025

-

Premium PVC Transparent Pipe: Durable & Clear Solutions

NewsJul.31,2025