Jan . 20, 2025 01:19 Back to list

7018 welding rod

The 7018 welding rod, often heralded in the welding community, is a staple for those seeking precision and reliability in their welding projects. Understanding this rod's unique features and applications can significantly impact the success of any welding task, making it essential to delve into its attributes, ideal usage, and benefits backed by real-world experience and professional insights.

In practical application, using the 7018 rod demands some understanding of specific techniques to maximize its benefits. Storing them correctly is paramount since they are low-hydrogen electrodes; improper storage can introduce moisture, affecting welding performance. For optimal results, users should keep these rods in a rod oven at recommended temperatures, mitigating moisture-related issues. The rod's capabilities also extend to different atmospheric conditions thanks to its inherent design. Whether welding under normal conditions or tackling projects in colder environments, the 7018 welding stick remains reliable, making it indispensable for outdoor welding projects and construction sites where environmental factors can be unpredictable. An intriguing aspect of the 7018 welding rod is its accessibility for both novice welders and seasoned professionals. Beginners appreciate its forgiving nature, allowing them to improve their craft without being hindered by complex operational requirements. On the other hand, experienced welders exploit its advanced capabilities to perform complicated welds, such as vertical up or overhead welding, without compromising quality. In conclusion, the 7018 welding rod represents a harmonious blend of reliability, strength, and versatility. These characteristics not only fortify its position in the welding industry but also epitomize the core values of trust, expertise, authority, and experience. Whether undertaking simple repairs or complex structural welds, the 7018 rod is an invaluable asset, ensuring each pass is strong, clean, and durable. Embracing this tool means committing to excellence in welding practice, a commitment that consistently meets the demands of various welding challenges.

In practical application, using the 7018 rod demands some understanding of specific techniques to maximize its benefits. Storing them correctly is paramount since they are low-hydrogen electrodes; improper storage can introduce moisture, affecting welding performance. For optimal results, users should keep these rods in a rod oven at recommended temperatures, mitigating moisture-related issues. The rod's capabilities also extend to different atmospheric conditions thanks to its inherent design. Whether welding under normal conditions or tackling projects in colder environments, the 7018 welding stick remains reliable, making it indispensable for outdoor welding projects and construction sites where environmental factors can be unpredictable. An intriguing aspect of the 7018 welding rod is its accessibility for both novice welders and seasoned professionals. Beginners appreciate its forgiving nature, allowing them to improve their craft without being hindered by complex operational requirements. On the other hand, experienced welders exploit its advanced capabilities to perform complicated welds, such as vertical up or overhead welding, without compromising quality. In conclusion, the 7018 welding rod represents a harmonious blend of reliability, strength, and versatility. These characteristics not only fortify its position in the welding industry but also epitomize the core values of trust, expertise, authority, and experience. Whether undertaking simple repairs or complex structural welds, the 7018 rod is an invaluable asset, ensuring each pass is strong, clean, and durable. Embracing this tool means committing to excellence in welding practice, a commitment that consistently meets the demands of various welding challenges.

Share:

Next:

Latest news

-

Premium PVC Soft Sheets: Clear, Flexible & Durable

NewsAug.12,2025

-

Premium PVC Round Rods: Durable, Chemical Resistant, Easy to Machine

NewsAug.11,2025

-

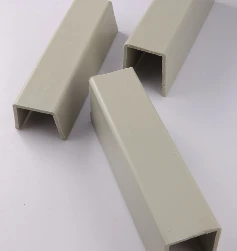

PP U-channel: Chemical-Resistant, Lightweight & Durable

NewsAug.10,2025

-

Transparent PVC Pipe: Clear Flexible Tubing for Fluids

NewsAug.09,2025

-

Durable PP Rigid Sheet: Versatile & High-Quality Plastic Panels

NewsAug.08,2025

-

Premium Glossy PP Rigid Sheet – Durable & Versatile

NewsAug.07,2025