Oct . 12, 2025 04:35 Back to list

PVC Rigid Sheet (Anti-Static) - ESD Safe, Durable, Cleanroom

PVC Rigid Sheet(anti-static) is a key solution in the manufacturing industry, specifically within the plastic product industry and the manufacturing of plastic plates, sheets, pipes, and profiles. This article explores how Baoding Lida Plastic Industry Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- PVC Rigid Sheet(anti-static) Overview

- Benefits & Use Cases of PVC Rigid Sheet(anti-static) in Manufacturing of plastic plates, sheets, pipes, and profiles

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on PVC Rigid Sheet(anti-static) from Baoding Lida Plastic Industry Co., Ltd

PVC Rigid Sheet(anti-static) Overview

PVC Rigid Sheet(anti-static) combines the mechanical strength of rigid PVC with engineered electrostatic dissipation to help protect sensitive processes and components. In practical terms, the sheet’s surface is formulated to keep surface resistivity within an ESD-safe range (commonly engineered into 106–109 Ω/sq, depending on grade), mitigating dust attraction and minimizing static discharge events. This makes it valuable wherever plastics are converted into plates, sheets, pipes, and profiles and then integrated into equipment guards, cleanroom partitions, jigs, fixtures, and handling trays.

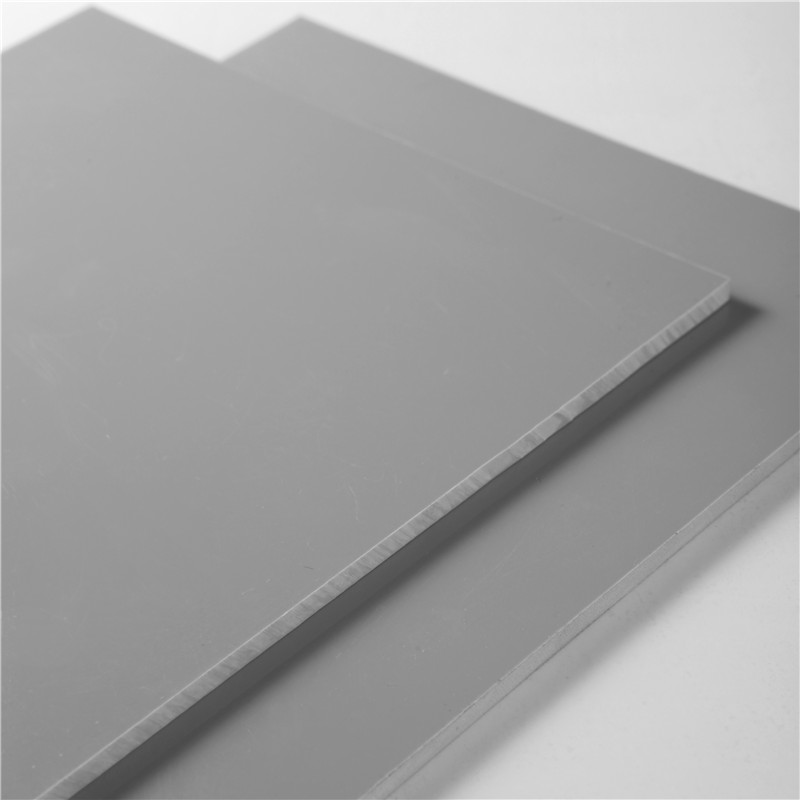

Typical options include multiple thicknesses, colors (e.g., gray, black, or translucent), and surface finishes (matte or gloss), with protective film available for fabrication. PVC offers inherent chemical resistance and is self-extinguishing, while remaining easy to machine, thermoform, and heat-bend. Baoding Lida Plastic Industry Co., Ltd manufactures these sheets with tight thickness tolerances and good flatness control to support CNC routing, drilling, and controlled forming operations. Technical datasheets and customized formulations are available upon request to align with sector-specific requirements in electronics, medical devices, and general industrial manufacturing.

Benefits & Use Cases of PVC Rigid Sheet(anti-static) in Manufacturing of plastic plates, sheets, pipes, and profiles

In downstream fabrication and assembly, PVC Rigid Sheet(anti-static) serves as a robust, ESD-aware substrate for machine guards, conveyor covers, cleanroom wall liners, workbench backsplashes, ESD-safe bins and dividers, and component carriers. Converters appreciate its dimensional stability, ease of cutting and routing, and its compatibility with mechanical fastening and solvent bonding. For extrusion and profiling lines, anti-static properties help reduce dust accumulation on guards and panels, supporting cleaner operations and lower maintenance.

Compared with many coated alternatives, anti-static PVC is cost-effective while delivering dependable static control and chemical resistance against acids, alkalis, and many industrial cleaners. It can be thermoformed into trays and hoods, bent for protective shrouds, or fabricated into modular partitions around sensitive processes. Baoding Lida Plastic Industry Co., Ltd brings sector know-how to each order—offering consistent quality, custom dimensions, color matching, and batch traceability—so OEMs, fabricators, and integrators can streamline projects without compromising on EHS or ESD requirements.

Cost, Maintenance & User Experience

Total cost of ownership favors PVC Rigid Sheet(anti-static) because it delivers strong durability at an accessible price point and reduces the risk of static-related damage or downtime. Users often find that anti-static grades reduce the frequency of cleaning in dusty environments and help minimize rework tied to particulate contamination. Permanent or semi-permanent anti-static formulations can extend service life and reduce the need for re-coating or replacement, strengthening ROI across multi-shift operations.

For maintenance, use soft, non-abrasive cloths and neutral pH cleaners; avoid harsh solvents and abrasives that could mar the surface. Store sheets flat, protected from UV and high heat, and handle with gloves to preserve optical quality where applicable. Fabricators report smooth machining with carbide tools, reliable edge quality, and predictable bending and forming behavior—key factors that shorten setup time and improve yield. In aggregate, buyers in the plastic product industry value the balance of performance, aesthetics, and processability that anti-static PVC provides.

Sustainability & Market Trends in manufacturing

Manufacturers are under pressure to meet EHS goals while staying competitive. Anti-static PVC solutions fit into this trajectory when sourced responsibly and processed in clean, efficient facilities. Baoding Lida Plastic Industry Co., Ltd prioritizes consistent quality and offers options that can be engineered to align with common regulatory expectations (e.g., RoHS/REACH-related requirements) as specified by customers. Pre-consumer scrap can be routed into controlled recycling streams, and material utilization can be optimized through cut-to-size services to reduce waste.

Market demand for ESD-safe materials continues to expand with the growth of electronics assembly, EV battery and energy storage production, medical device manufacturing, and high-spec industrial automation. Standards-driven environments—such as those referencing ANSI/ESD practices—are prompting more conversions from standard plastics to anti-static substrates for panels, partitions, and handling systems. As a forward-thinking supplier, Baoding Lida monitors these trends and invests in formulation options, dimensional ranges, and process consistency to support customers’ sustainability and compliance roadmaps.

Conclusion on PVC Rigid Sheet(anti-static) from Baoding Lida Plastic Industry Co., Ltd

PVC Rigid Sheet(anti-static) offers an effective mix of mechanical strength, chemical resistance, and ESD performance for businesses operating in the manufacturing of plastic plates, sheets, pipes, and profiles. With reliable fabrication behavior and a favorable cost profile, it helps B2B decision makers protect processes, improve cleanliness, and reduce risk. Baoding Lida Plastic Industry Co., Ltd backs every order with dependable quality and responsive customization.

Contact us: email: lidaplastic@ldsy.cn

Visit our website: https://www.lidaplastic.com

-

Comprehensive Guide To HDPE Pipes and Fittings | Durable & Sustainable Solutions

NewsNov.24,2025

-

HDPE Culvert Pipe – Durable, Flexible & Sustainable Infrastructure Solutions

NewsNov.24,2025

-

DWC HDPE Pipe – Durable, Cost-Effective Drainage and Conduit Solutions

NewsNov.23,2025

-

HDPE Drainage Pipe – Durable and Sustainable Water Management Solutions

NewsNov.23,2025

-

Durable and Sustainable HDPE Corrugated Pipe Solutions for Modern Infrastructure

NewsNov.23,2025

-

HDPE Water Pipe - Durable, Cost-Effective Water Solutions for Global Needs

NewsNov.22,2025